Modified novolac epoxy resin hot melt adhesive

A phenolic epoxy resin, hot melt adhesive technology, applied in the direction of in-line phenolic epoxy resin adhesives, adhesives, oil/grease/wax adhesives, etc., can solve the viscosity of phenolic epoxy resin hot melt adhesives, etc. Insufficient performance, etc., to achieve the effects of excellent thermal stability, excellent initial viscosity, and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

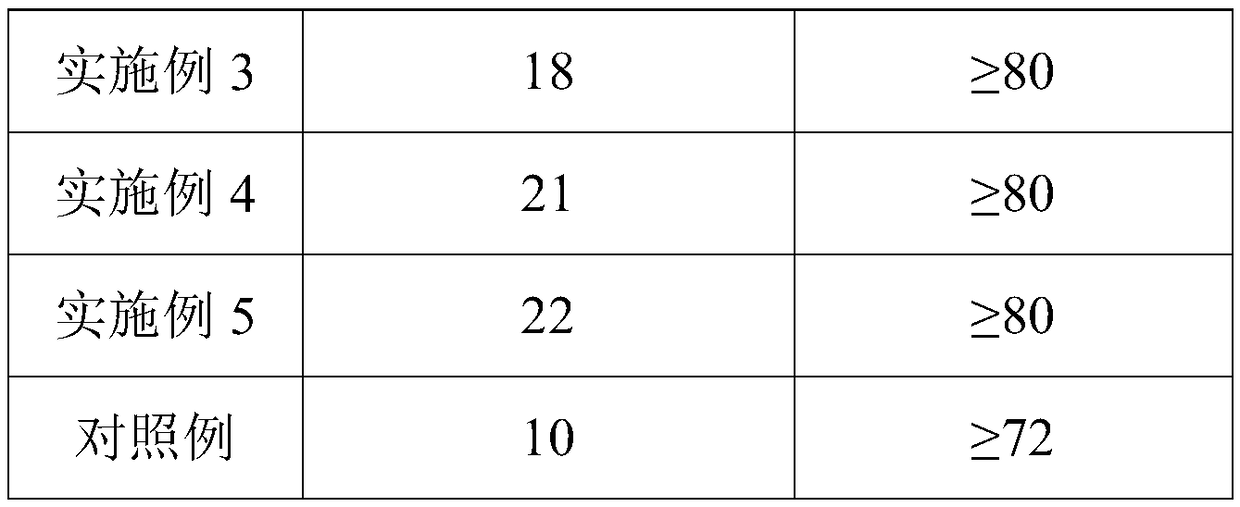

Examples

Embodiment 1

[0016] A modified phenolic epoxy resin hot melt adhesive, the raw materials of which include by weight: 2 parts of phenolic epoxy resin, 20 parts of polyurethane resin, 2.8 parts of lapis lazuli powder, 5 parts of compound oil, 2 parts of microcrystalline wax, phthalate 0.9 parts of di-n-nonyl dicarboxylate, 1.3 parts of benzoin, 2.5 parts of antioxidant BHT, and 3.5 parts of bauxite.

Embodiment 2

[0018] A modified phenolic epoxy resin hot melt adhesive, the raw materials of which include by weight: 60 parts of phenolic epoxy resin, 1.2 parts of polyurethane resin, 12 parts of lapis lazuli powder, 1.5 parts of compound oil, 6 parts of microcrystalline wax, phthalate 0.2 part of di-n-nonyl dicarboxylate, 4.7 parts of benzoin, 0.1 part of antioxidant BHT, 10 parts of bauxite;

[0019] Wherein, the novolac epoxy resin is a modified novolac epoxy resin; the preparation method of the modified novolac epoxy resin is: mixing novolak epoxy resin and α-methylcinnamaldehyde solution, heating up to 70°C, The reaction was carried out for 2.5 h under vacuum stirring to obtain a modified novolac epoxy resin.

Embodiment 3

[0021] A modified phenolic epoxy resin hot melt adhesive, the raw materials of which include by weight: 5 parts of phenolic epoxy resin, 15 parts of polyurethane resin, 3 parts of lapis lazuli powder, 4.5 parts of compound oil, 3 parts of microcrystalline wax, o-benzene 0.8 parts of di-n-nonyl dicarboxylate, 1.5 parts of benzoin, 2.1 parts of antioxidant BHT, 4.5 parts of bauxite;

[0022] Wherein, the novolac epoxy resin is a modified novolac epoxy resin; the preparation method of the modified novolac epoxy resin is: mixing the novolac epoxy resin and α-methyl cinnamaldehyde solution evenly, heating up to 85°C, Reaction 2h under vacuum stirring, obtains modified novolac epoxy resin;

[0023] The solvent of the α-methylcinnamaldehyde solution is ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com