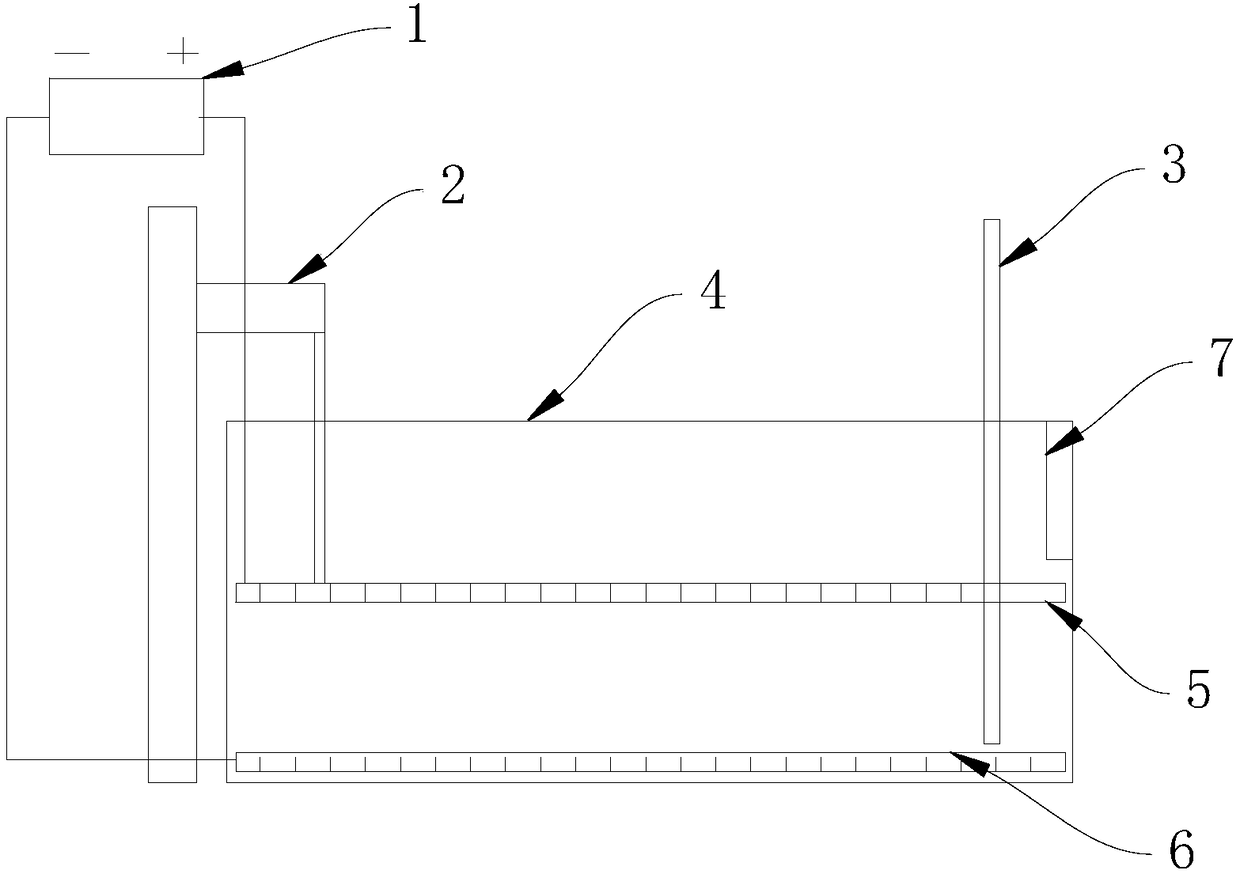

Graphene electrochemical reduction dyeing device and method

A technology of graphene electrochemical and dyeing devices, which is applied in the field of graphene electrochemical reduction dyeing devices, can solve problems such as endangering workers' health and environmental pollution, and achieve the effects of improving production efficiency, reducing production costs, and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

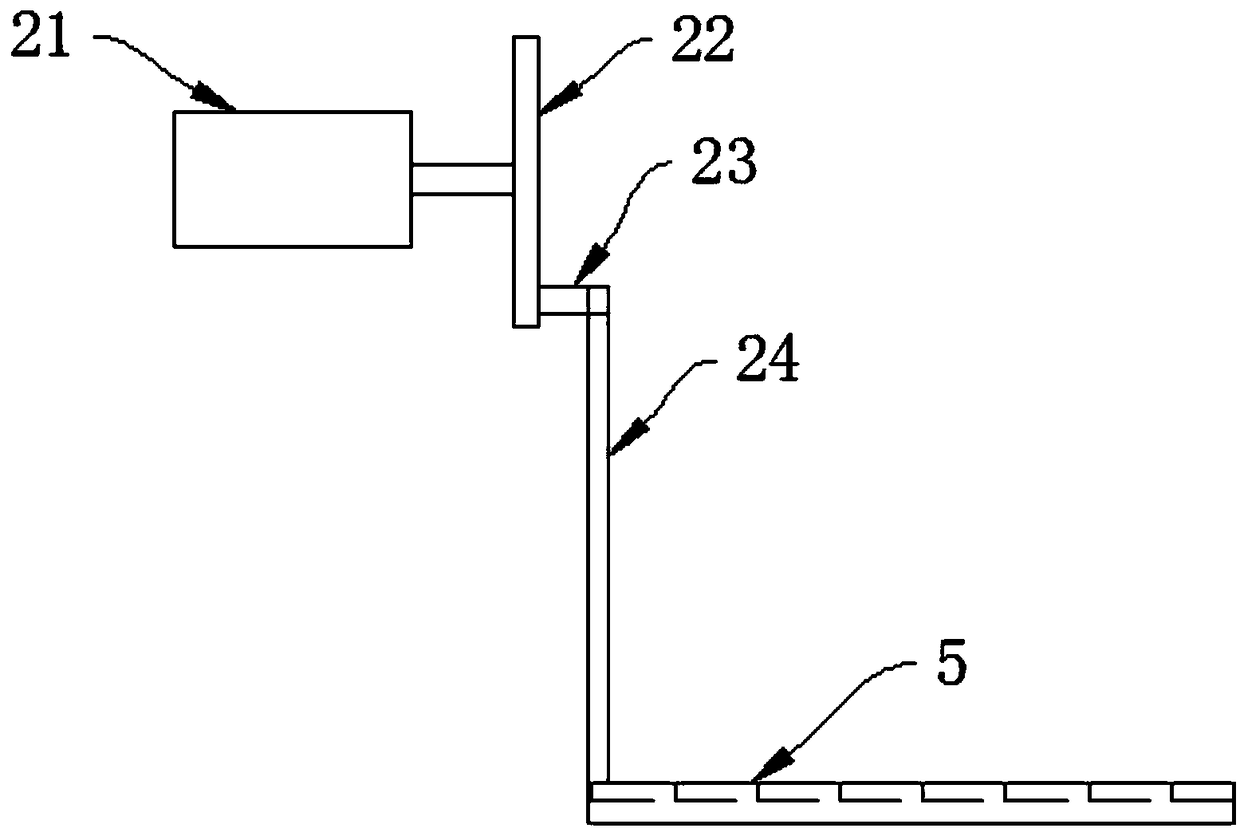

Method used

Image

Examples

Embodiment 1

[0042] In the electrolytic cell, sodium hydroxide aqueous solution, triethanolamine and sulfur dyes are sequentially added to prepare an electrolyte, wherein the concentration of sodium hydroxide in the electrolyte is 0.15mol / L, the concentration of triethanolamine is 0.02mol / L, and the sulfur dye The concentration is 0.01mol / L. Turn on the driving device and connect to the DC power supply. The 100-mesh steel plate of the anode grid stirs the electrolyte and starts the electrochemical reduction reaction. Adding an appropriate amount of ion migration aid can speed up the reduction efficiency of sulfur dyes. The current density is 0.5 ampere / square decimeter, and the electric current reduction is 30 minutes, and the measured current efficiency is 82.3%.

Embodiment 2

[0044]In the electrolytic cell, sodium hydroxide aqueous solution, triethanolamine and sulfur dyes are sequentially added to prepare an electrolyte, wherein the concentration of sodium hydroxide in the electrolyte is 0.2mol / L, the concentration of triethanolamine is 0.15mol / L, and the sulfur dye The concentration is 0.02mol / L. Turn on the driving device and connect to the DC power supply. The 150-mesh steel plate of the anode grid stirs the electrolyte and starts the electrochemical reduction reaction. Adding an appropriate amount of ion transfer additive can speed up the reduction efficiency of sulfur dyes. The current density is 0.7 ampere / square decimeter, and the electric current reduction is 30 minutes, and the measured current efficiency is 83.4%.

Embodiment 3

[0046] In the electrolytic cell, sodium hydroxide aqueous solution, triethanolamine and sulfur dyes are sequentially added to prepare an electrolyte, wherein the concentration of sodium hydroxide in the electrolyte is 0.1mol / L, the concentration of triethanolamine is 0.1mol / L, and the concentration of sulfur dye is 0.1mol / L. The concentration is 0.15mol / L. Turn on the driving device and connect to the DC power supply. The 100-mesh nickel plate of the anode grid stirs the electrolyte and starts the electrochemical reduction reaction. Adding an appropriate amount of ion transfer additive can speed up the reduction efficiency of sulfur dyes. The temperature of the electrolyte is 30°C. The electrolytic current density is 0.5 ampere / square decimeter, and the electric current reduction is 30 minutes, and the measured current efficiency is 80.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com