Polyhydroxy POSS-modified reverse osmosis composite membrane and preparation method thereof

A technology of reverse osmosis composite membrane and silsesquioxane, which is applied in the direction of semi-permeable membrane separation, reverse osmosis, chemical instruments and methods, etc., can solve the problems of no improvement in chlorine resistance and membrane pollution resistance, and achieve Effects of high permeability and separation performance, increase in free volume, and enhanced permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

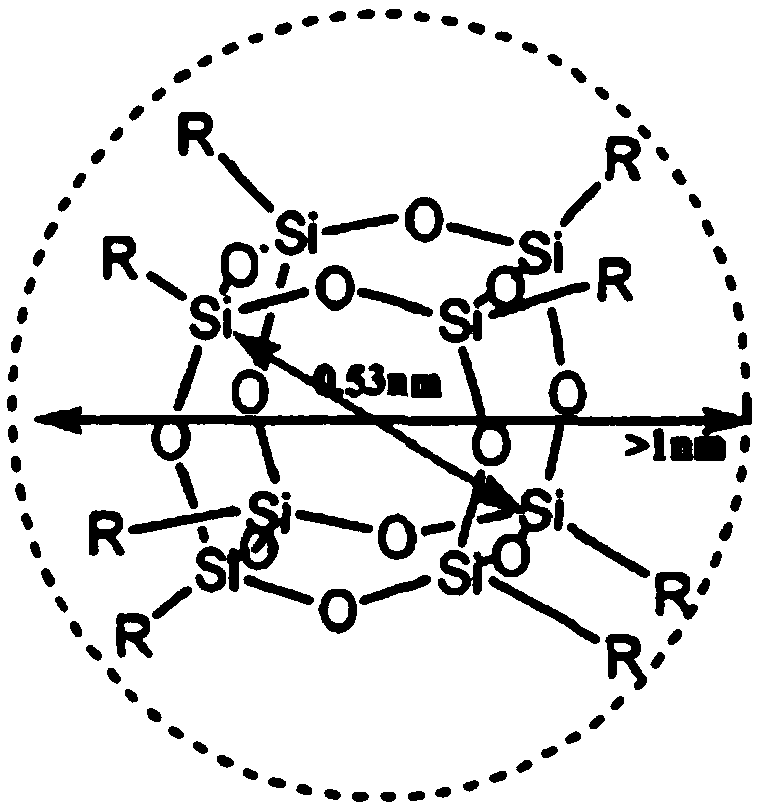

[0027] As an aspect of the technical solution of the present invention, it relates to a method for preparing a reverse osmosis composite membrane modified by polyhydroxy cage silsesquioxane, which includes:

[0028] The base film is first contacted with a reaction system containing polyhydroxyl-functionalized cage silsesquioxane nanoparticles and polyamines, and then contacted with polybasic acid chlorides, and the polyhydroxyl-functionalized caged silsesquioxane nanoparticles Particles, polyamines and polyacyl chlorides are subjected to interfacial polymerization to obtain a reverse osmosis composite membrane modified by polyhydroxy cage silsesquioxane.

[0029] In some embodiments, the preparation method specifically includes:

[0030] providing an aqueous polyamine solution comprising the polyhydroxyl-functionalized cage silsesquioxane nanoparticles;

[0031] The base film is soaked in the polyamine aqueous solution, and then soaked in the polyacyl chloride organic solutio...

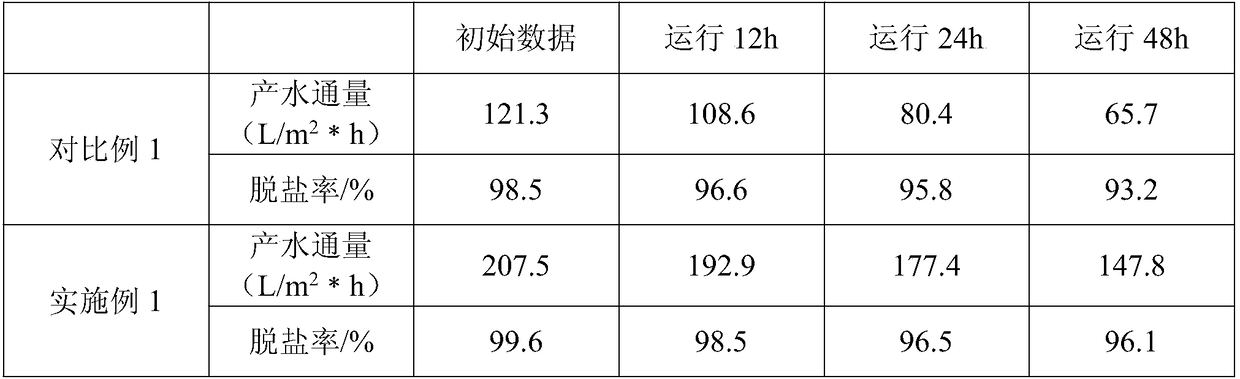

Embodiment 1

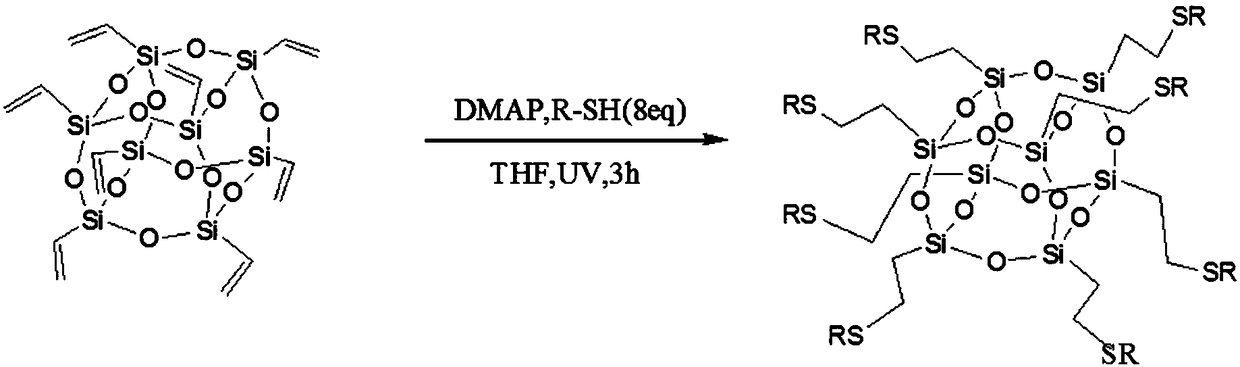

[0075] Step 1. Preparation of Octahydroxyl Functionalized Caged Silsesquioxane Nanoparticles

[0076] Octahydroxyl-functionalized cage silsesquioxane nanoparticles are prepared by click chemistry of octavinyl silsesquioxane (OvPOSS) and small molecules of mercapto alcohols, and the reaction mechanism is double bond-thiol-ene Free radical addition. First, the initiator is excited by absorbing photons under the action of heat or light, cracks and generates free radicals; then, the newly generated free radicals will capture a hydrogen atom (H) on the mercapto group (-SH) to generate mercapto free radicals. Then the mercapto free radical will attack the carbon-carbon double bond (C=C), and the active center will transfer to generate a carbon free radical; process, the free radical addition of thiol-double bond (thiol-ene) can be completed, and its typical chemical reaction formula is as follows figure 2 shown.

[0077] Step 2. Prepare basement membrane

[0078] Polysulfone-ba...

Embodiment 2

[0088]This example is basically the same as Example 1, except that in Step 3, the ratio of octahydroxy-functionalized cage-type silsesquioxane nanoparticles to m-phenylenediamine is 1:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com