A kind of graphene functionalized nano needle tip and preparation method thereof

A technology of graphene function and needle tip, which is applied in the field of functionalization of metal materials, can solve the problems of inability to prepare graphene functionalized probes and uncontrollable tip structure, and achieve excellent electrical properties, excellent needle tip morphology, and sharp tip tips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

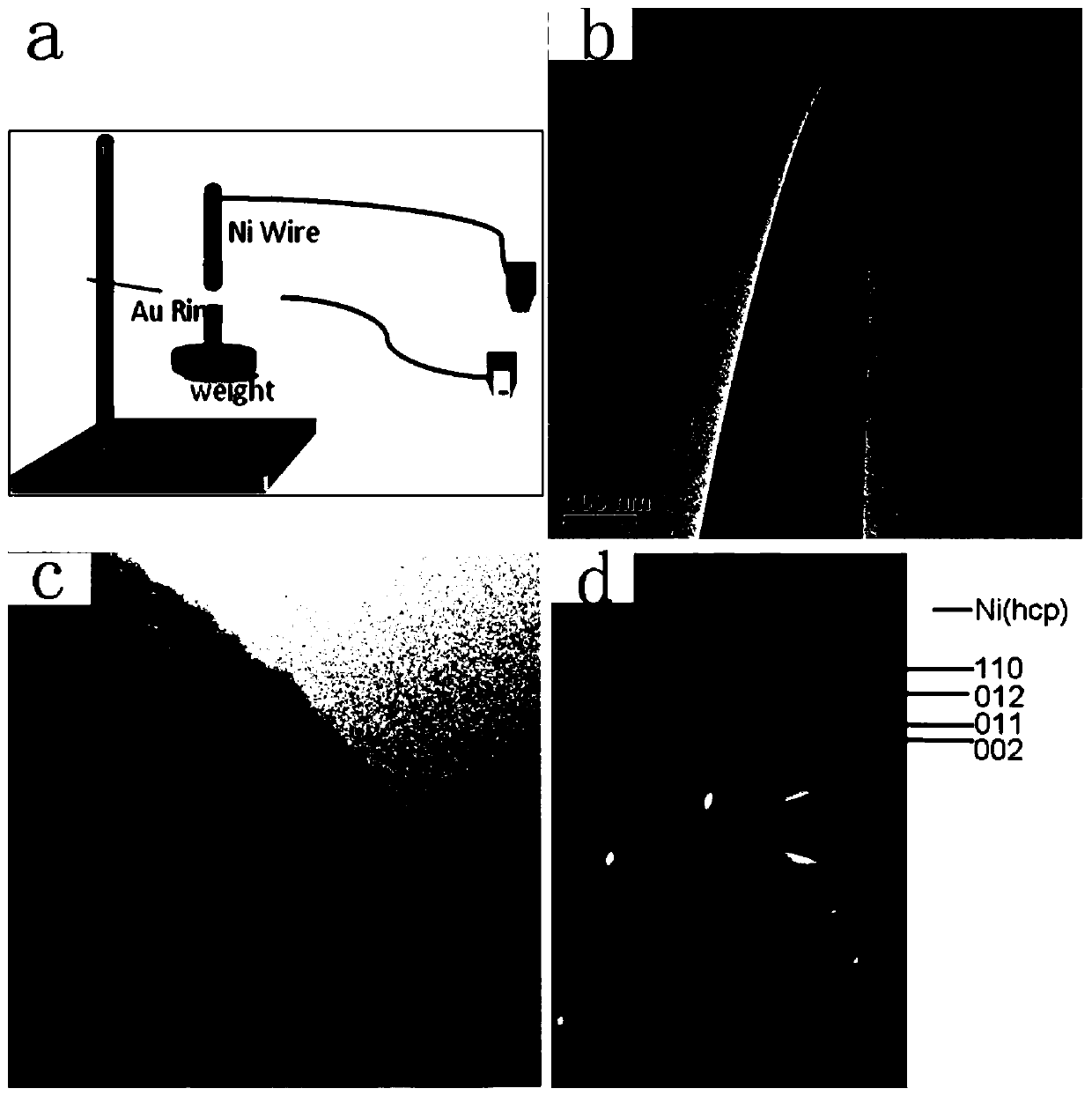

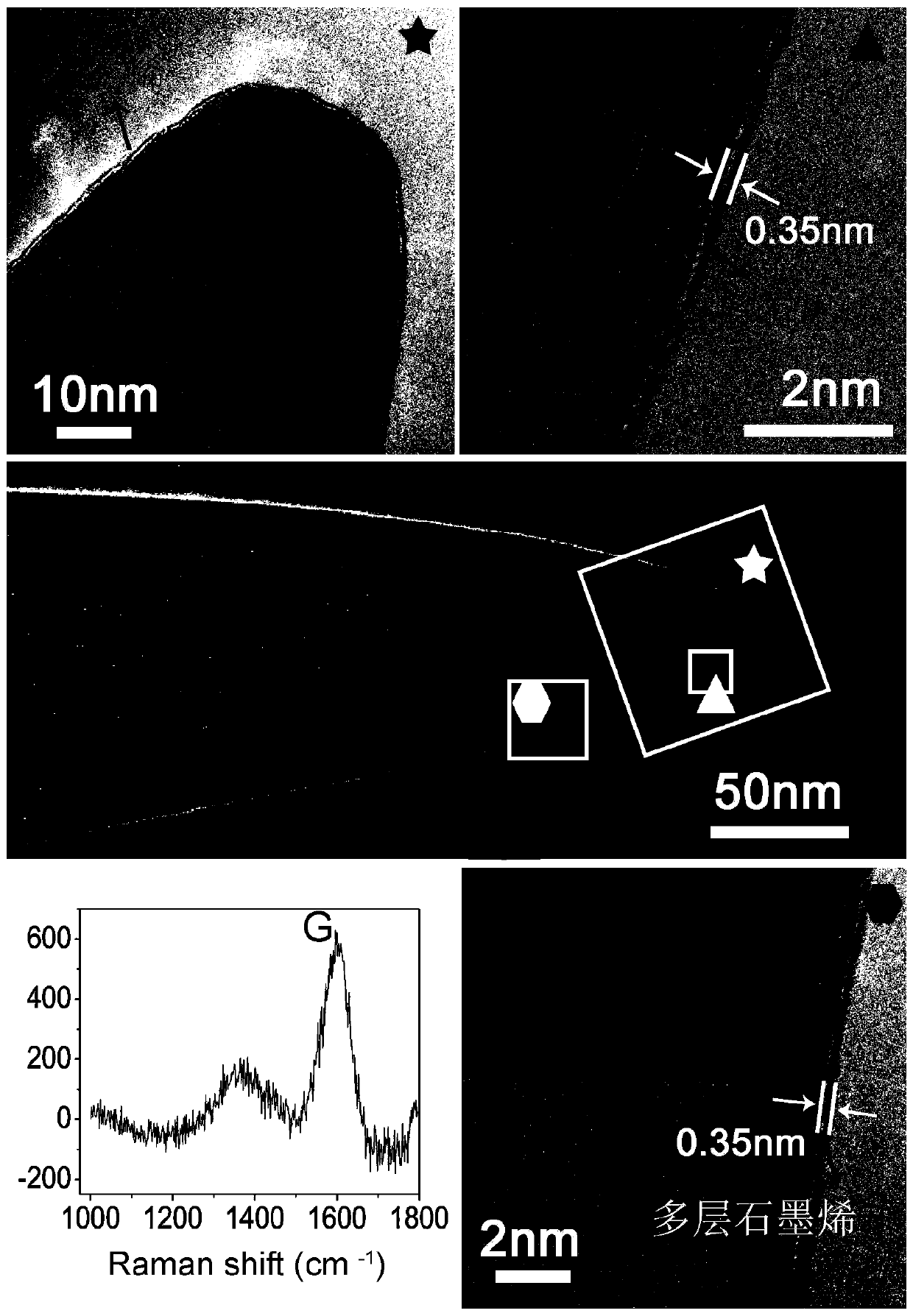

[0046] Metal Ni needle tips with a tip diameter of about 30nm were prepared by electrochemical corrosion method. figure 1 A schematic diagram of the device for preparing the original nickel needle by electrochemical corrosion method, the nickel wire is connected to the positive pole of the power supply, and the gold ring is connected to the negative pole of the power supply. The 1M KCl liquid film on the gold ring was used to gradually corrode the Ni wire to finally obtain the Ni needle tip. figure 1 b is the TEM image of the generated nickel needle, the surface of the needle tip is smooth, and the tip size is about 30nm. figure 1 c corresponds to the HR-TEM image of the nickel needle tip, figure 1 The d is the corresponding SAED pattern. The apex angle of the tip of the needle tip is about 30°.

[0047] The Ni needle tip was rinsed with a large amount of water, soaked in dilute acetic acid to remove the surface oxide layer, rinsed with a large amount of water, and dried wi...

Embodiment 2

[0053] Metal Ni needle tips with a tip diameter of about 30nm were prepared by electrochemical corrosion method. The Ni needle tip was rinsed with a large amount of water, soaked in dilute acetic acid to remove the surface oxide layer, rinsed with a large amount of water, and dried with nitrogen. The above-mentioned Ni needle tip was fixed vertically in an autoclave, and 100 μL of triethylene glycol solution with a purity of 99% was added, while 450 μL of a 0.1 mol / L NaOH solution was added and mixed well. The above reaction kettle was placed in a muffle furnace, heated to 220°C at a heating rate of 5°C / min and kept for 2 hours, and then cooled down naturally.

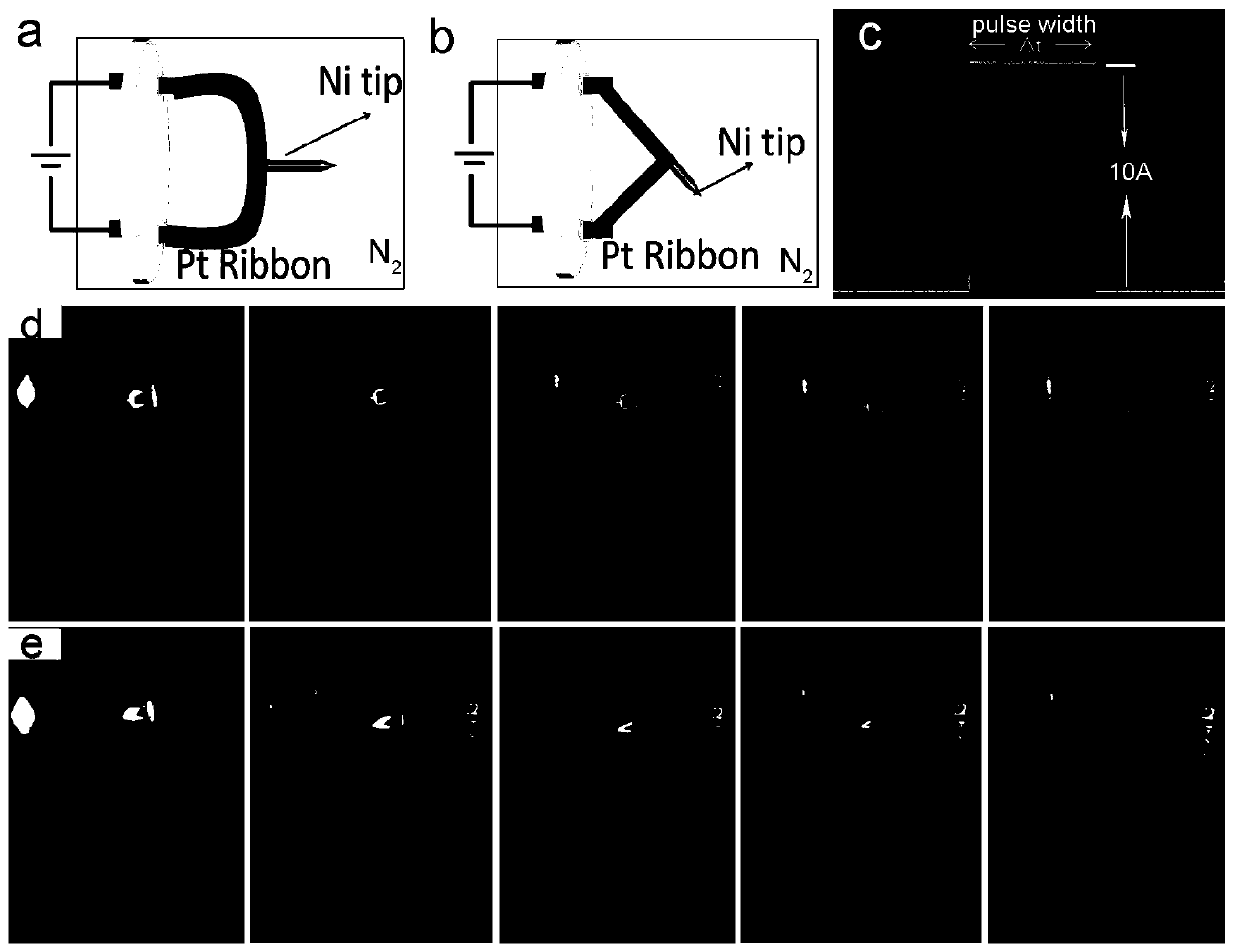

[0054] Take out the above-mentioned Ni needle tip, rinse it with a large amount of water, dry it with nitrogen, and spot weld it in the middle of the metal Pt strip with a length of 25mm*width 0.85mm*thickness 0.05mm; the metal Pt strip is bent into a U shape, and the two ends are spot-welded and fixed on the ceramic ...

Embodiment 3

[0057] Metal Ni needle tips with a tip diameter of about 30nm were prepared by electrochemical corrosion method. The Ni needle tip was rinsed with a large amount of water, soaked in dilute acetic acid to remove the surface oxide layer, rinsed with a large amount of water, and dried with nitrogen. The above-mentioned Ni needle tip was fixed vertically in an autoclave, and 100 μL of triethylene glycol solution with a purity of 99% was added, while 450 μL of a 0.1 mol / L NaOH solution was added and mixed well. The above reactor was placed in a muffle furnace, heated to 220°C at a rate of 5°C / min for 2 hours, and then cooled naturally.

[0058] The above-mentioned Ni needle tip was taken out, rinsed with a large amount of water, and dried with nitrogen gas. The tip of the needle tip was fixed on the corundum needle holder, and then the needle holder was placed in the heating area of the tube furnace. Use a molecular pump to vacuum the cavity to 10 -5 Turn off the pump after Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com