Synthetic method for pharmaceutical intermediate p-chlorobenzoic acid

A technology of p-chlorobenzoic acid and a synthesis method, which is applied in the field of synthesis of a pharmaceutical intermediate p-chlorobenzoic acid, can solve the problems of complicated process and low final yield, and can reduce intermediate links, shorten reaction time, and improve reaction yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

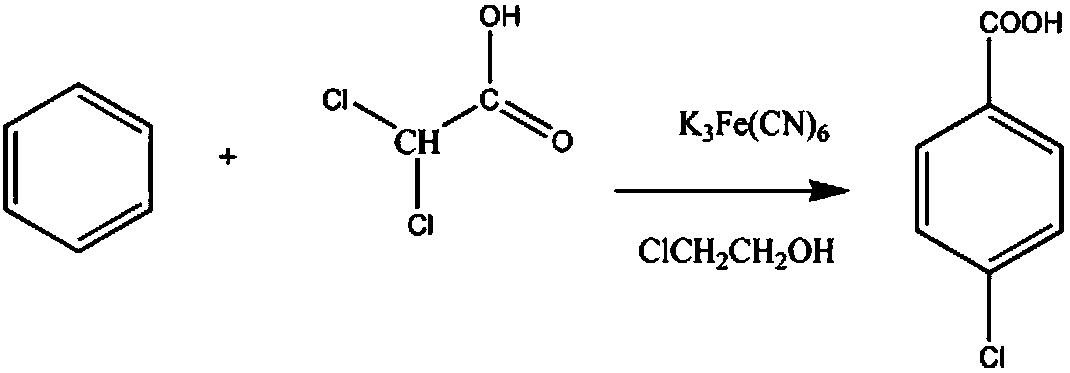

Image

Examples

example 1

[0011] Add 3L of 2-chloroethanol solution with a mass fraction of 30% into the reaction vessel, control the stirring speed at 90rpm, add 2mol of benzene solution with a mass fraction of 50%, 3mol of dichloroacetic acid, and 30g of potassium ferricyanide powder, and increase the temperature of the solution to Keep at 70°C for 70 minutes, lower the solution temperature to 10°C, precipitate solids, filter, wash the solids with 60% aniline solution, combine the washing liquid and filtrate, adjust the pH to 2 with 25% oxalic acid solution, and precipitate precipitates , filtered, the solid was washed with 45% potassium nitrate solution by mass fraction, washed by 70% 2-octanol solution by mass fraction, washed by 80% 2-butoxyethanol solution by mass fraction, dehydrated by anhydrous calcium sulfate dehydrating agent , to get 266.22 g of finished p-chlorobenzoic acid, yield 85%.

example 2

[0013] Add 3L of 2-chloroethanol solution with a mass fraction of 35% into the reaction vessel, control the stirring speed at 100rpm, add 2mol mass fraction of 53% benzene solution, 3.5mol of dichloroacetic acid, 30g of potassium ferricyanide powder, and raise the temperature of the solution to 70°C, keep it for 70min, lower the solution temperature to 10°C, precipitate solids, filter, wash the solids with 62% aniline solution, combine the washing liquid and filtrate, adjust the pH to 2.5 with 27% oxalic acid solution, and precipitate Precipitate, filter, wash the solid with 47% potassium nitrate solution, 73% 2-octanol solution, 83% 2-butoxyethanol solution, solid sodium hydroxide dehydrating agent After dehydration, 278.75 g of p-chlorobenzoic acid was obtained, with a yield of 89%.

example 3

[0015] Add 3L of 39% 2-chloroethanol solution into the reaction vessel, control the stirring speed to 110rpm, add 2mol of 57% benzene solution, 4mol of dichloroacetic acid, 40g of potassium ferricyanide powder, and increase the temperature of the solution to Keep at 80°C for 80 minutes, lower the temperature of the solution to 16°C, precipitate solids, filter, wash the solids with 65% aniline solution, combine the washing liquid and filtrate, adjust the pH to 3 with 30% oxalic acid solution, and precipitate precipitates , filtered, the solid was washed with 50% potassium nitrate solution by mass fraction, washed by 76% 2-octanol solution, 87% by 2-butoxyethanol solution, anhydrous calcium sulfate dehydrating agent After dehydration, 288.14 g of p-chlorobenzoic acid was obtained, with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com