Biodegradable plastic film and preparation method thereof

A technology of plastic film and degradable masterbatch, applied in the field of degradable plastic film and its preparation, can solve the problems of inability to degrade automatically, harm to the environment and human body, etc., and achieve the effects of formula safety, improving soil environment and accelerating the degradation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

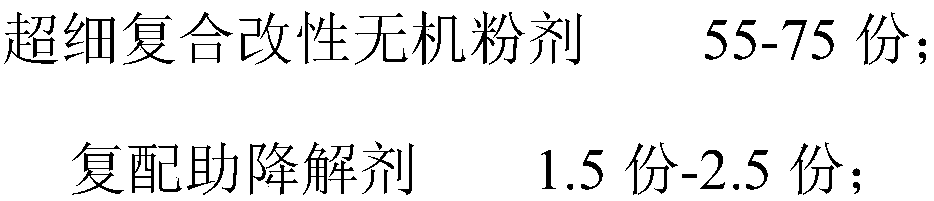

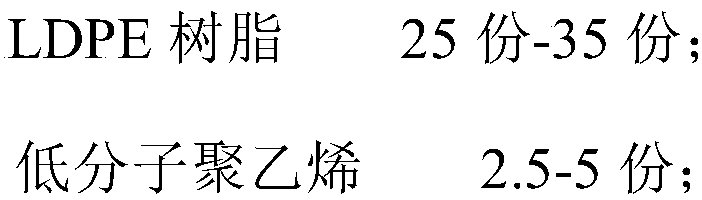

[0032] A degradable plastic film, the main resin of the degradable film is LDPE resin and LLDPE resin with a mass ratio of 3:1; and 30% composite modified polyolefin degradation masterbatch is added to the main resin; the Composite modified polyolefin degradation masterbatch, including the following raw materials in parts by weight:

[0033]

[0034] Described superfine composite modification inorganic powder comprises the raw material of following weight:

[0035] 85 parts of composite modified superfine ground calcium carbonate;

[0036] Nanoscale SiO 2 10 copies;

[0037] KH-550 silane coupling agent 0.5 parts.

[0038] The particle size D97≤1μm of the composite modified superfine ground calcium carbonate; the nano-scale SiO 2 The particle size is 80-100nm.

[0039] The silane coupling agent is KH-550; the compound degradation aid is FeSt 3 -MnSt 2 and biosurfactant, the weight ratio of the two is 10:1; the MRF=2-4g / 10min of the LDPE resin.

[0040] The preparat...

Embodiment 2

[0053] A degradable plastic film, the main resin of the degradable film is LDPE resin and LLDPE resin with a mass ratio of 3:1; and 30% composite modified polyolefin degradation masterbatch is added to the main resin; the Composite modified polyolefin degradation masterbatch, including the following raw materials in parts by weight:

[0054]

[0055] Described superfine composite modification inorganic powder comprises the raw material of following weight:

[0056] 90 parts of composite modified superfine ground calcium carbonate;

[0057] Nanoscale SiO 2 13 copies;

[0058] KH-550 silane coupling agent 0.8 parts.

[0059] The particle size D97≤1μm of the composite modified superfine ground calcium carbonate; the nano-scale SiO 2 The particle size is 80-100nm.

[0060] The silane coupling agent is KH-550; the compound degradation aid is FeSt 3 -MnSt 2 and biosurfactant, the weight ratio of the two is 10:1; the MRF=2-4g / 10min of the LDPE resin.

[0061] The preparat...

Embodiment 3

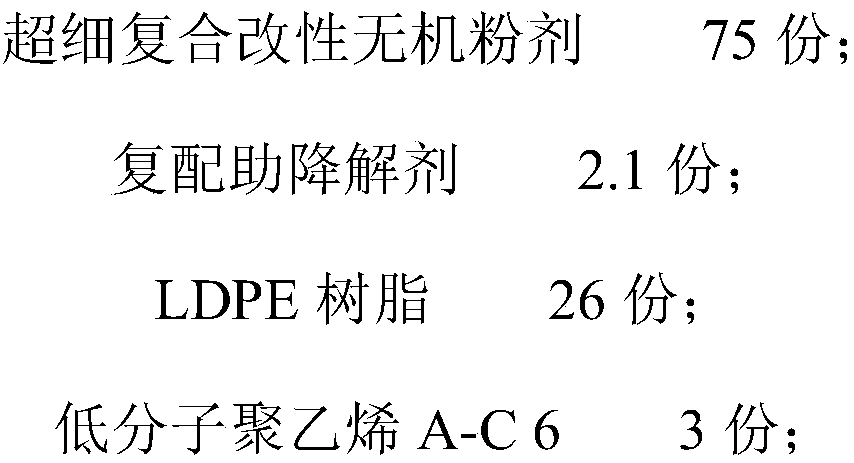

[0068] A degradable plastic film, the main resin of the degradable film is LDPE resin and LLDPE resin with a mass ratio of 3:1; and 30% composite modified polyolefin degradation masterbatch is added to the main resin; the Composite modified polyolefin degradation masterbatch, including the following raw materials in parts by weight:

[0069]

[0070] Described superfine composite modification inorganic powder comprises the raw material of following weight:

[0071] 88 parts of composite modified superfine ground calcium carbonate;

[0072] Nanoscale SiO 2 11 copies;

[0073] KH-550 silane coupling agent 1 part.

[0074] The particle size D97≤1μm of the composite modified superfine ground calcium carbonate; the nano-scale SiO 2 The particle size is 80-100nm.

[0075] The silane coupling agent is KH-550; the compound degradation aid is FeSt 3 -MnSt 2 and biosurfactant, the weight ratio of the two is 10:1; the MRF of the LDPE resin=2-4g / 10min.

[0076] The preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com