A kind of sintered rare-earth permanent magnet material added with vc and preparation method thereof

A rare earth permanent magnet and sintered magnet technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as grain coarsening, achieve small grain size, improve comprehensive magnetic properties, and eliminate obvious problems. The effect of microporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

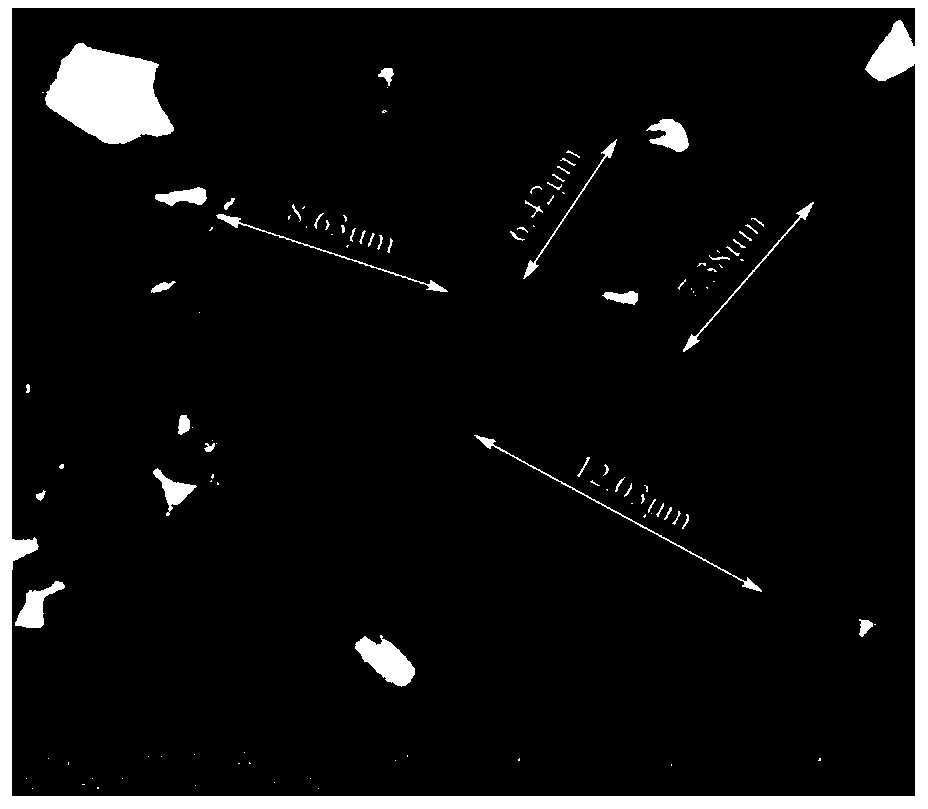

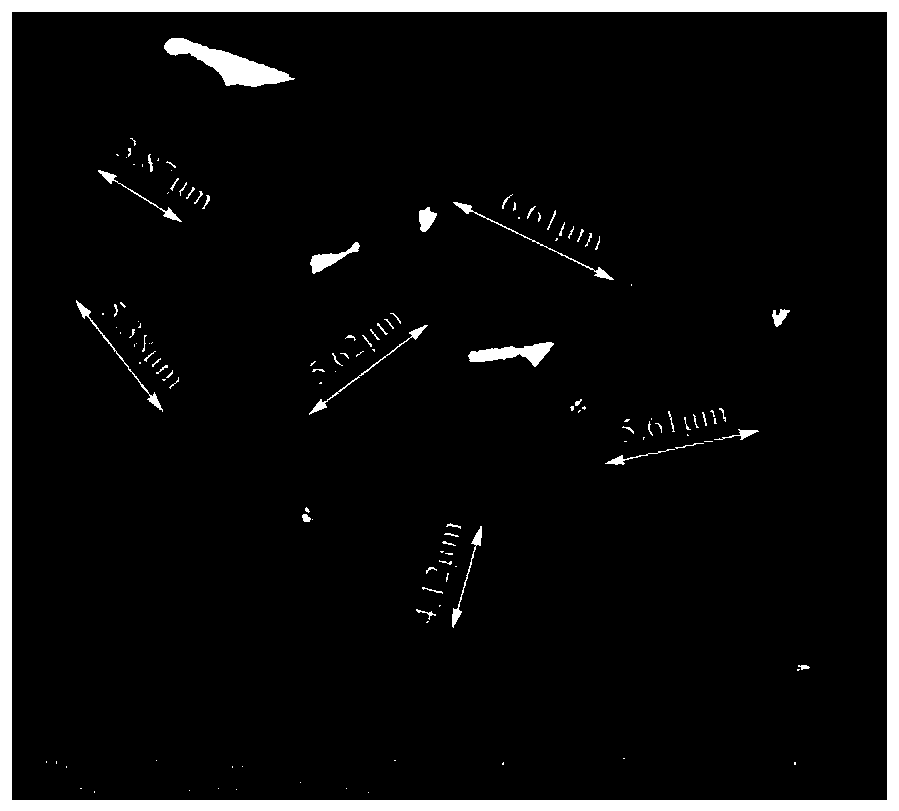

Image

Examples

Embodiment 1

[0046] The sintered rare earth permanent magnet material prepared in this embodiment has the chemical formula of Nd 29.89 Fe 63.62 co 4.93 Ga 0.64 B 0.92 The magnet is composed of vanadium carbide, and the process steps are as follows:

[0047] (1) Ingredients

[0048] Dosing according to the chemical formula of the above-mentioned magnets, and remove the oxides and impurities on the surface of the raw materials;

[0049] (2) Casting

[0050] Put the prepared raw materials in step (1) into a vacuum induction melting furnace and melt them under the condition of high-purity argon gas. Quick-setting alloy cast sheet with a thickness of 0.25mm;

[0051] (3) Preparation of magnetic powder

[0052] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen crushing treatment to obtain coarsely crushed alloy particles with a particle size of 10-300 μm, and carry out jet mill crushing of the obtained alloy coarsely crushed particles und...

Embodiment 2

[0068] The sintered rare earth permanent magnet material prepared in this embodiment has the chemical formula of Nd 32.92 Fe 65.07 co 1.0 B 1.01 The magnet is composed of vanadium carbide, and the process steps are as follows:

[0069] (1) Ingredients

[0070] Dosing according to the chemical formula of the above-mentioned magnets, and remove the oxides and impurities on the surface of the raw materials;

[0071] (2) Casting

[0072] Put the raw materials prepared in step (1) into a vacuum induction melting furnace and melt them under the condition of high-purity argon. After melting, pour the alloy liquid on a water-cooled copper roller with a linear speed of 3.5m / s, and then quickly cool it to obtain Quick-setting alloy cast sheet with an average thickness of 0.22mm;

[0073] (3) Preparation of magnetic powder

[0074] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen crushing treatment to obtain coarsely crushed alloy...

Embodiment 3

[0090] The sintered rare earth permanent magnet material prepared by the present embodiment has the chemical formula of (Nd, Pr) 32.52 Fe 65.08 co 0.79 B 0.71 Ga 0.2 al 0.4 Cu 0.3 The magnet is composed of vanadium carbide, and the process steps are as follows:

[0091] (1) Ingredients

[0092] Dosing according to the chemical formula of the above-mentioned magnets, and remove the oxides and impurities on the surface of the raw materials;

[0093] (2) Casting

[0094] Put the prepared raw materials in step (1) into a vacuum induction melting furnace and melt them under the condition of high-purity argon gas. Quick-setting alloy cast sheet with a thickness of 0.25mm;

[0095] (3) Preparation of magnetic powder

[0096] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen crushing treatment to obtain coarsely crushed alloy particles with a particle size of 10-300 μm, and carry out jet mill crushing of the obtained alloy co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com