A kind of Ⅱ-type core-shell structure quantum dot and its preparation method and application

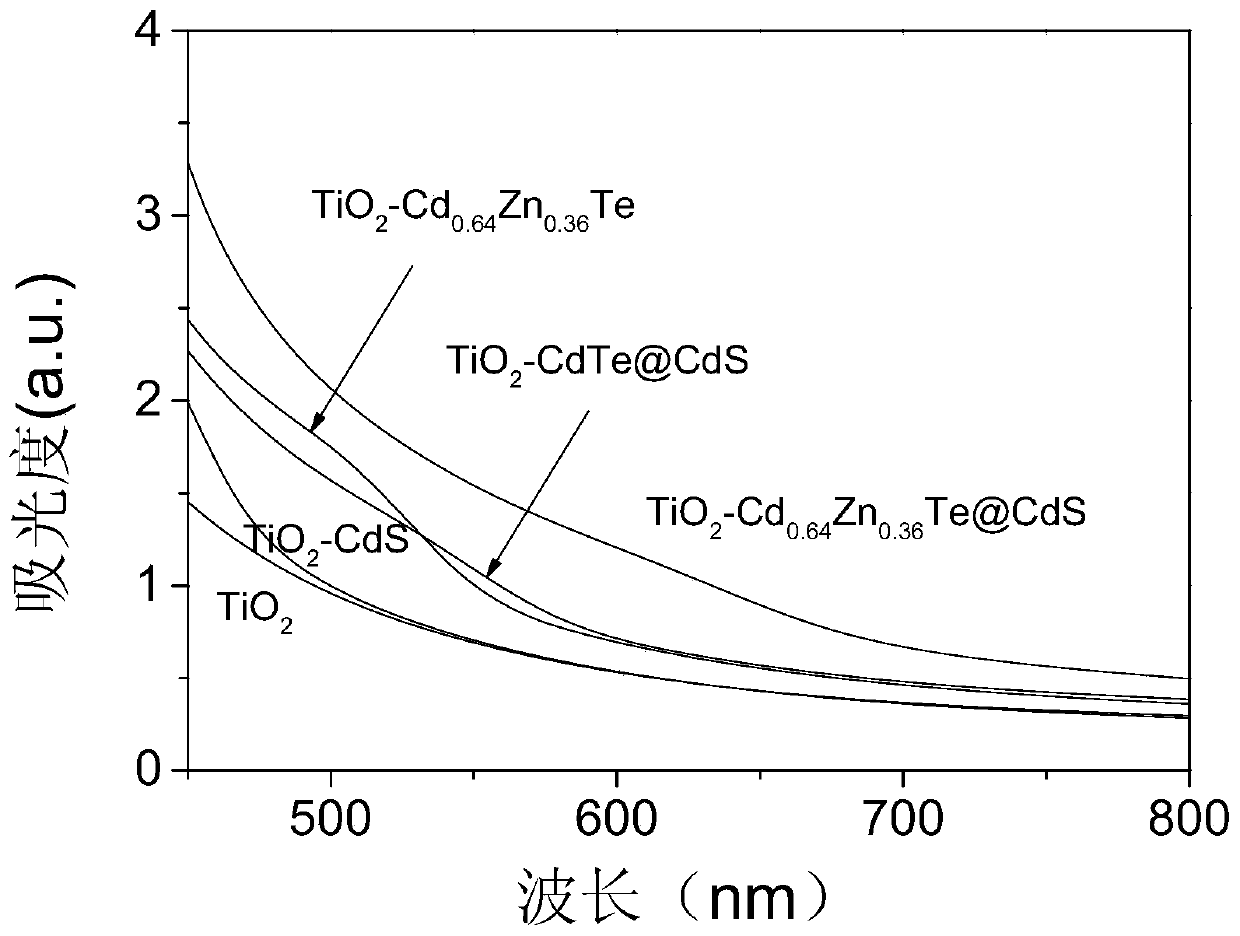

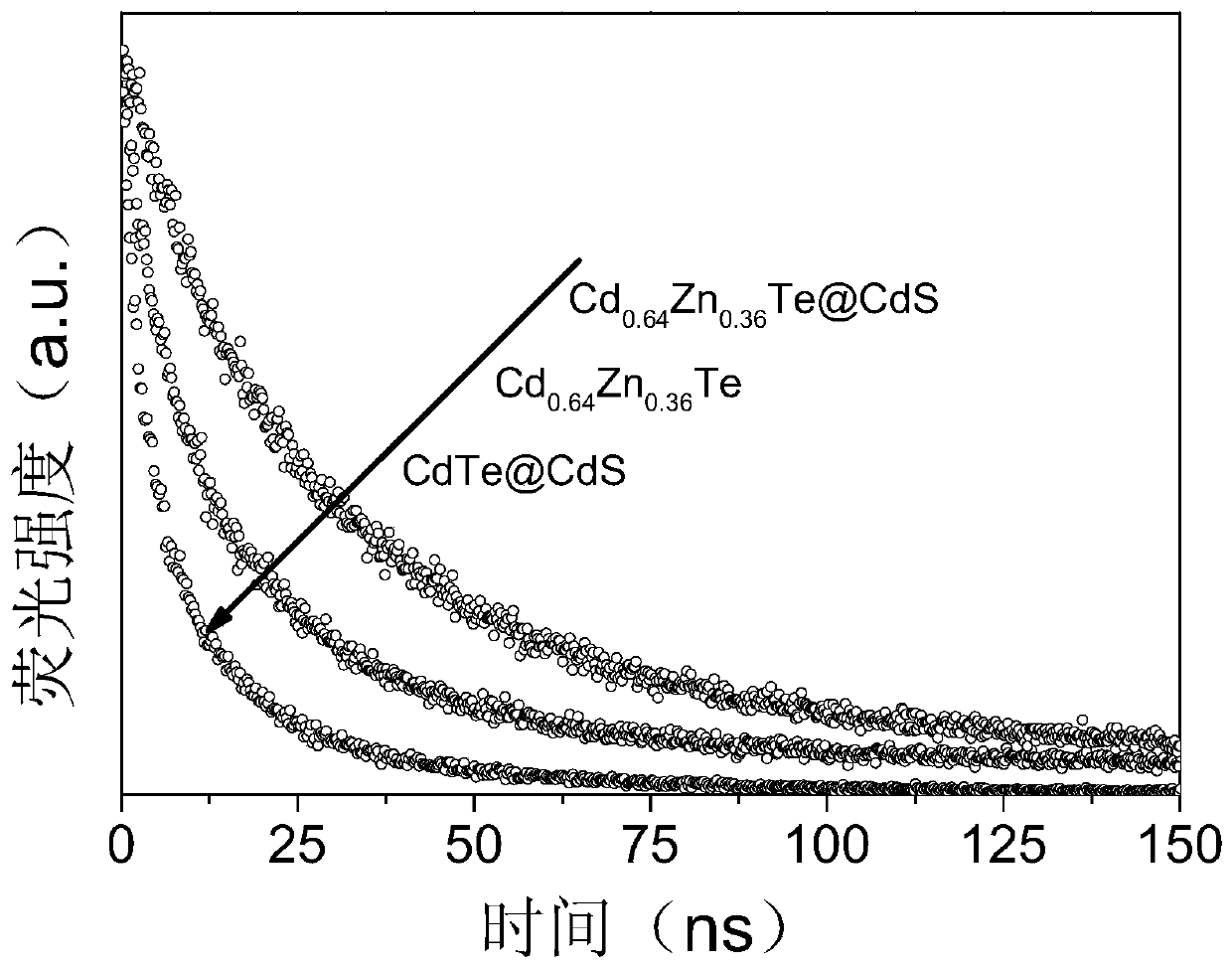

A technology of core-shell structure and quantum dots, which is applied in the field of sensitized solar cells, can solve problems such as the elimination of unfavorable holes, and achieve the effects of loose shell thickness, reduced difficulty, and excellent photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

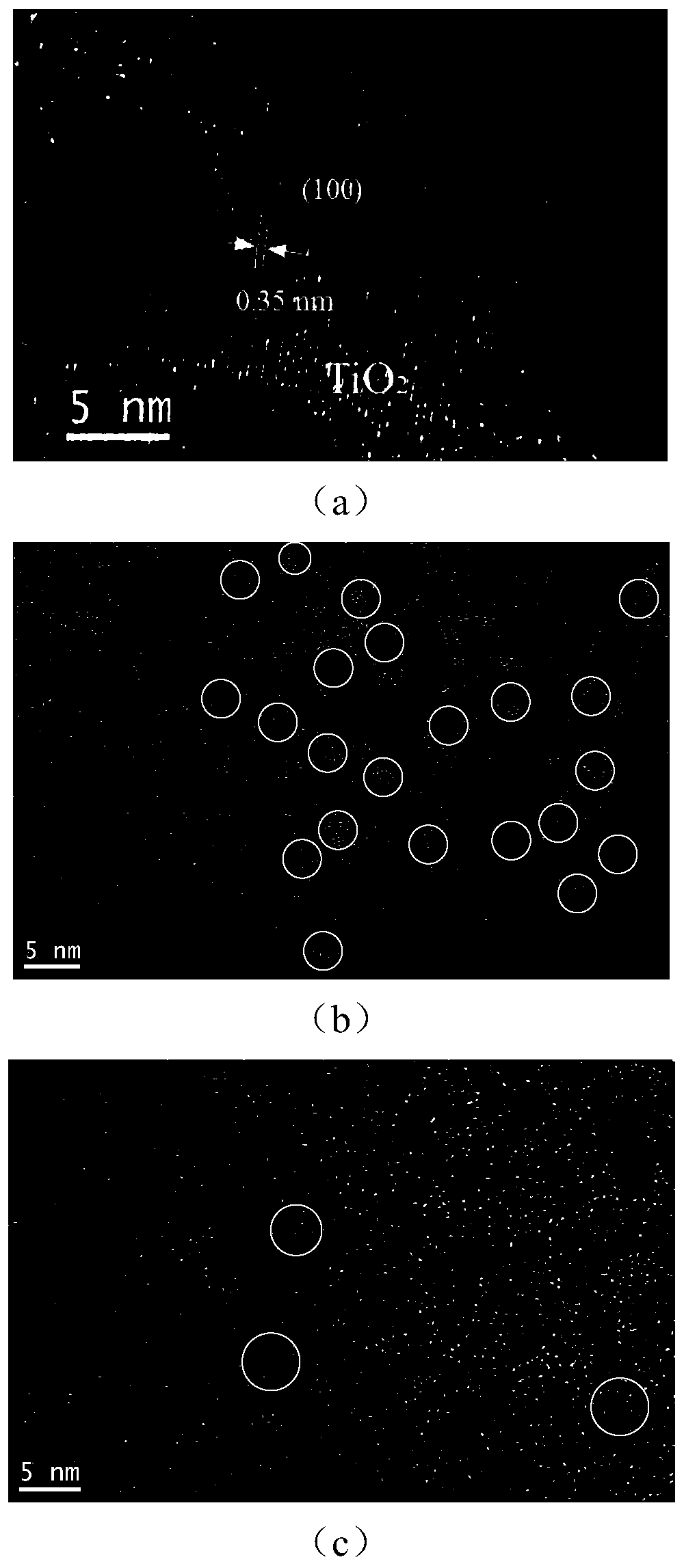

[0054] (1) Preparation of titanium dioxide dense layer:

[0055] TiO by screen printing 2 The slurry (P25) is evenly spread on the screen, and the material is scraped lightly and quickly with a scraper. Then place the conductive surface of the conductive glass directly under the screen plate, and quickly scrape TiO 2 The paste allows it to be printed onto conductive glass. TiO 2 The film was placed in a sealed box with a small amount of ethanol, and stood for 3 minutes. Under the atmosphere of ethanol vapor, the TiO 2 The film is naturally leveled, transferred to an oven, and dried at 125°C.

[0056] (2) Preparation of Cd by aqueous phase method 0.64 Zn 0.36 Te (feeding ratio Cd / Zn=1 / 1) quantum dots:

[0057] Sodium borohydride and tellurium powder are used as raw materials, deionized water is used as a solvent, and a transparent sodium telluride hydride solution is formed by reacting at 30°C for 2-3 hours in a nitrogen atmosphere. with CdCl 2 , ZnCl 2 As raw materia...

Embodiment 2

[0081] (1) Preparation of titanium dioxide dense layer:

[0082] TiO was screen-printed 2 The slurry (P25) is spread evenly on the wire mesh, and the material is applied lightly and quickly with a scraper. Then place the conductive surface of the conductive glass directly under the screen plate, and quickly scrape the TiO with force 2 The paste makes it print onto conductive glass. the TiO 2 The film was placed in a sealed box with a small amount of ethanol, and stood for 3 min. Under the atmosphere of ethanol vapor, the TiO 2 The film was naturally leveled, transferred to an oven, and dried at 125°C.

[0083] (2) Preparation of Cd by aqueous method 0.37 Zn 0.63 Te (feeding ratio Cd / Zn=1 / 3) quantum dots:

[0084] Using sodium borohydride and tellurium powder as raw materials and deionized water as solvent, in a nitrogen atmosphere, react at 30 °C for 2-3 hours to form a transparent sodium tellurium hydride solution. with CdCl 2 , ZnCl 2 As raw material, mercaptopropi...

Embodiment 3

[0092] (1) Preparation of titanium dioxide dense layer:

[0093] TiO was screen-printed 2 The slurry (P25) is spread evenly on the wire mesh, and the material is applied lightly and quickly with a scraper. Then place the conductive surface of the conductive glass directly under the screen plate, and quickly scrape the TiO with force 2 The paste makes it print onto conductive glass. the TiO 2 The film was placed in a sealed box with a small amount of ethanol, and stood for 3 min. Under the atmosphere of ethanol vapor, the TiO 2 The film was naturally leveled, transferred to an oven, and dried at 125°C.

[0094] (2) Preparation of Cd by aqueous method 0.14 Zn 0.86 Te (feeding ratio Cd / Zn=1 / 7) quantum dots:

[0095] Using sodium borohydride and tellurium powder as raw materials and deionized water as solvent, in a nitrogen atmosphere, react at 30 °C for 2-3 hours to form a transparent sodium tellurium hydride solution. with CdCl 2 , ZnCl 2 As raw material, mercaptopropi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com