Modified diatomite additive for electrolyte for lithium battery and preparation method

A diatomaceous earth and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as flatulence, achieve the effects of improving viscosity stability, reducing flatulence, and improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

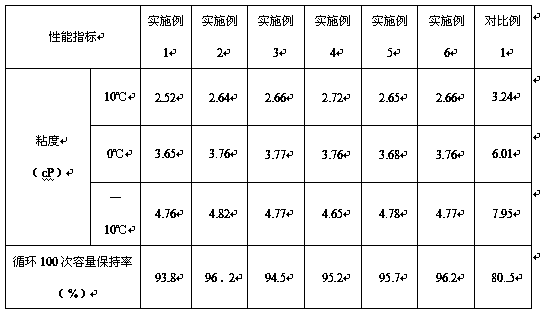

Examples

Embodiment 1

[0033] The preparation process is:

[0034] (1) The starch ether solution was prepared by etherified starch and deionized water; the etherified starch was hydroxyalkyl starch; the mass concentration of the starch ether solution was 4%;

[0035] (2) Use sodium hydroxide to adjust the starch ether solution to strong alkalinity; the pH of the starch ether solution is 11;

[0036] (3) Add fatty acid and diatomite powder to the starch ether solution, heat and cook for 110 minutes; the ratio of raw materials is 70 parts by weight of starch ether solution, 7 parts by weight of fatty acid, and 23 parts by weight of diatomite powder; the cooking temperature is 93°C ;

[0037] (4) Use dilute hydrochloric acid to adjust the system to strong acidity; the pH of the system is 2;

[0038] (5) Filter and wash with deionized water until neutral;

[0039] (6) Vacuum drying and dehydration to prepare the electrolyte modified diatomite additive for lithium batteries; the temperature of vacuum ...

Embodiment 2

[0041] The preparation process is:

[0042] (1) The starch ether solution is prepared by etherified starch and deionized water; the etherified starch is carboxymethyl starch; the mass concentration of the starch ether solution is 3%;

[0043] (2) Use sodium hydroxide to adjust the starch ether solution to strong alkalinity; the pH of the starch ether solution is 11;

[0044] (3) Add fatty acid and diatomite powder to the starch ether solution, heat and cook for 95 minutes; the ratio of raw materials is 71 parts by weight of starch ether solution, 7 parts by weight of fatty acid, and 22 parts by weight of diatomite powder; the cooking temperature is 91°C ;

[0045](4) Use dilute hydrochloric acid to adjust the system to strong acidity; the pH of the system is 2;

[0046] (5) Filter and wash with deionized water until neutral;

[0047] (6) Vacuum drying and dehydration to prepare the electrolyte modified diatomite additive for lithium batteries; the temperature of vacuum dryi...

Embodiment 3

[0049] The preparation process is:

[0050] (1) The starch ether solution was prepared by etherified starch and deionized water; the etherified starch was cationic starch; the mass concentration of the starch ether solution was 4.6%;

[0051] (2) Use sodium hydroxide to adjust the starch ether solution to strong alkalinity; the pH of the starch ether solution is 11;

[0052] (3) Add fatty acid and diatomite powder to the starch ether solution, heat and cook for 140 minutes; the ratio of raw materials is 63 parts by weight of starch ether solution, 9 parts by weight of fatty acid, and 28 parts by weight of diatomite powder; the cooking temperature is 95°C ;

[0053] (4) Use dilute hydrochloric acid to adjust the system to strong acidity; the pH of the system is 2;

[0054] (5) Filter and wash with deionized water until neutral;

[0055] (6) Vacuum drying and dehydration to prepare the electrolyte modified diatomite additive for lithium batteries; the temperature of vacuum dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com