Clean utilization method of coal slime produced in coal mining process

A mining process and coal slime technology, applied in the field of clean utilization of coal slime, can solve problems such as unfavorable coal mining work, difficulty in obtaining economic benefits, and difficulty in direct utilization, etc., and achieve good biological nutrition replenishment effect, good market economy effect, The effect of solving blockage and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

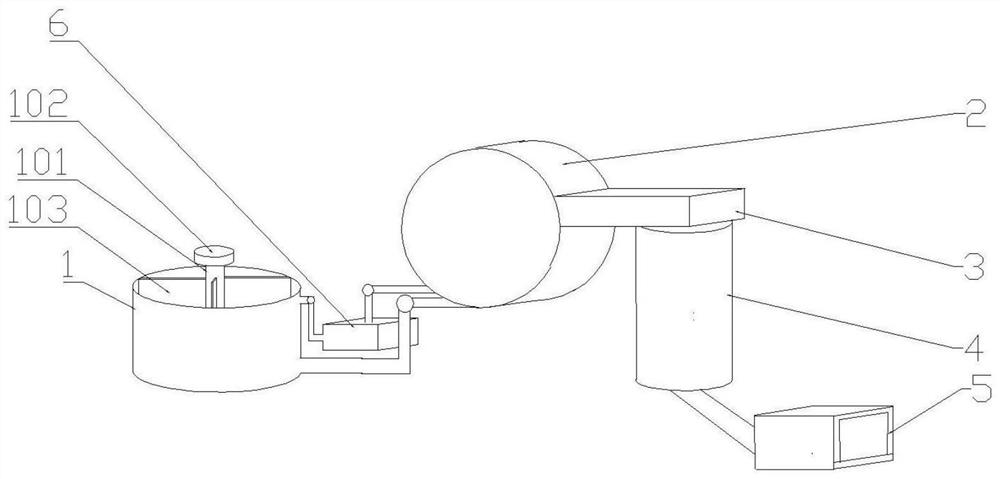

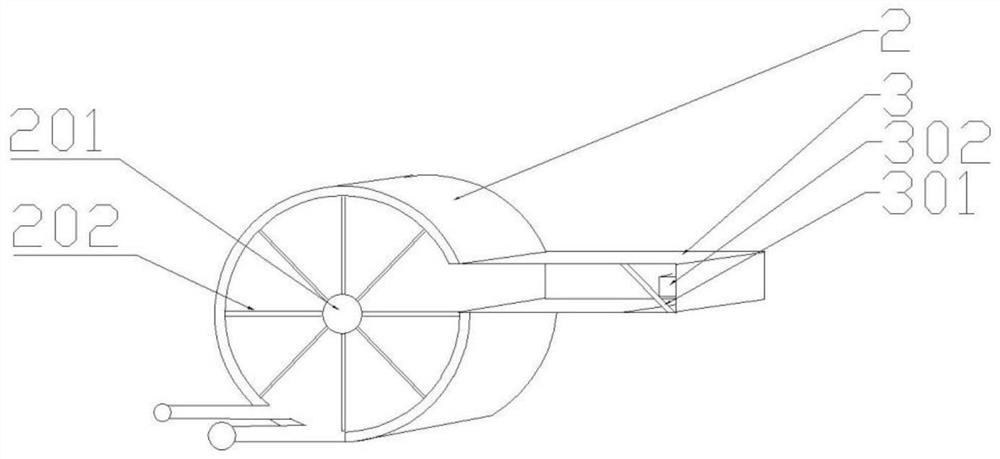

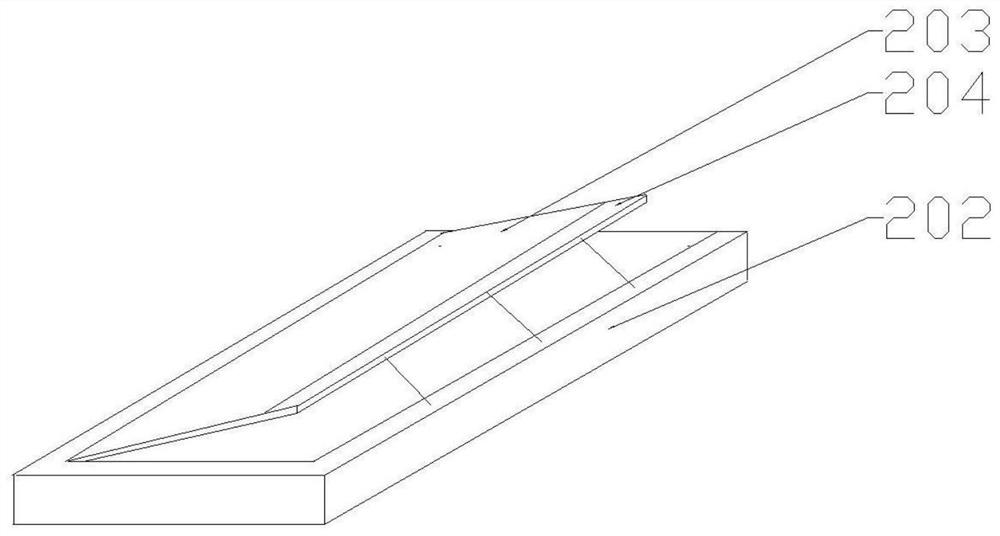

[0050] A method for clean utilization of coal slime produced during coal mining, including:

[0051] S1. Putting the coal slime in a coal slime treatment device for pretreatment to obtain coal slime powder, putting the coal slime powder into a blast burner for combustion to obtain coal slime powder;

[0052] S2. Add 10 parts by weight of straw, 15 parts by weight of corn silk, 20 parts by weight of mixed fertilizer, 10 parts by weight of inorganic fertilizer and 60 parts by weight of water to 160 parts by weight of the coal slime powder and mix uniformly to obtain Mixture;

[0053] S3, then put the mixture into the drum, and place it at 60°C and a wind speed of 15m / s, after fermenting for 10 days, spread out and spray 50 parts by weight of wormwood water with a mass fraction of 20%, and then reset Sealed fermentation at 60°C for 3 days, then adding 15 parts by weight of Bacillus and 25 parts by weight of Saccharomyces cerevisiae, fermenting at 30°C for 5 days, drying until th...

Embodiment 2

[0056] A method for clean utilization of coal slime produced during coal mining, including:

[0057] S1. Putting the coal slime in a coal slime treatment device for pretreatment to obtain coal slime powder, putting the coal slime powder into a blast burner for combustion to obtain coal slime powder;

[0058] S2. Add 25 parts by weight of straw, 20 parts by weight of corn silk, 30 parts by weight of mixed fertilizer, 20 parts by weight of inorganic fertilizer and 80 parts by weight of water to 200 parts by weight of the coal slime powder and mix uniformly to obtain Mixture;

[0059] S3, then put the mixture into the drum, and put it under 70°C and 30m / s wind speed, after fermenting for 15 days, spread out and spray 80 parts by weight of wormwood water with a mass fraction of 30%. Sealed fermentation at 70°C for 5 days, then adding 20 parts by weight of Bacillus and 30 parts by weight of Saccharomyces cerevisiae, fermenting at 40°C for 8 days, drying until the water content is ...

Embodiment 3

[0062] A method for clean utilization of coal slime produced during coal mining, including:

[0063] S1. Putting the coal slime in a coal slime treatment device for pretreatment to obtain coal slime powder, putting the coal slime powder into a blast burner for combustion to obtain coal slime powder;

[0064] S2. Add 18 parts by weight of stalks, 18 parts by weight of corn silk, 25 parts by weight of mixed fertilizer, 15 parts by weight of inorganic fertilizer and 70 parts by weight of water to 180 parts by weight of the coal slime powder and mix them uniformly to obtain Mixture;

[0065] S3, then put the mixture into the drum, and place it at 65°C and a wind speed of 22m / s, after fermentation for 12 days, spread out and spray 75 parts by weight of wormwood water with a mass fraction of 25% and then reset Sealed fermentation at 65°C for 4 days, then adding 18 parts by weight of Bacillus and 28 parts by weight of Saccharomyces cerevisiae, fermenting at 35°C for 6 days, drying u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com