Synthesis method for increasing polycarbosilane (PCS) yield

A technology of polycarbosilane yield and polycarbosilane, which is applied in the synthesis field of improving polycarbosilane yield, can solve problems such as low PCS synthesis yield, waste of manpower and material resources, and waste of materials, so as to improve process improvement efficiency and avoid Emissions, the effect of improving the synthesis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Put 360g of PDMS in a three-necked flask, raise the temperature to 420°C for 8 hours under the protection of nitrogen, and carry out pyrolysis rearrangement reaction to prepare P-PCS;

[0038] (2) Dissolve the P-PCS obtained in step (1) with 200ml of xylene, filter and distill, distill at 350°C for 1 hour to remove the xylene, and distill at 350°C for 1 hour to obtain the product PCS and the distilled LPCS, PCS The yield is 31%;

[0039] (3) LPCS is recovered and mixed with 360g PDMS, and steps (1) and (2) are repeated;

[0040] (4) When the above steps were repeated until the 8th time, the amount of LPCS added was 145g, and the recovered LPCS was 145g equally, and the yield of PCS was 40% at this moment.

[0041] The process of using PDMS as raw material to synthesize PCS for the first time can be regarded as the traditional method for synthesizing PCS. In contrast, the yield of PCS is increased from 31% to 40%.

Embodiment 2

[0043] (1) Put 360g of PDMS in a three-necked flask, raise the temperature to 450°C for 8 hours under the protection of nitrogen, and carry out pyrolysis rearrangement reaction to prepare P-PCS;

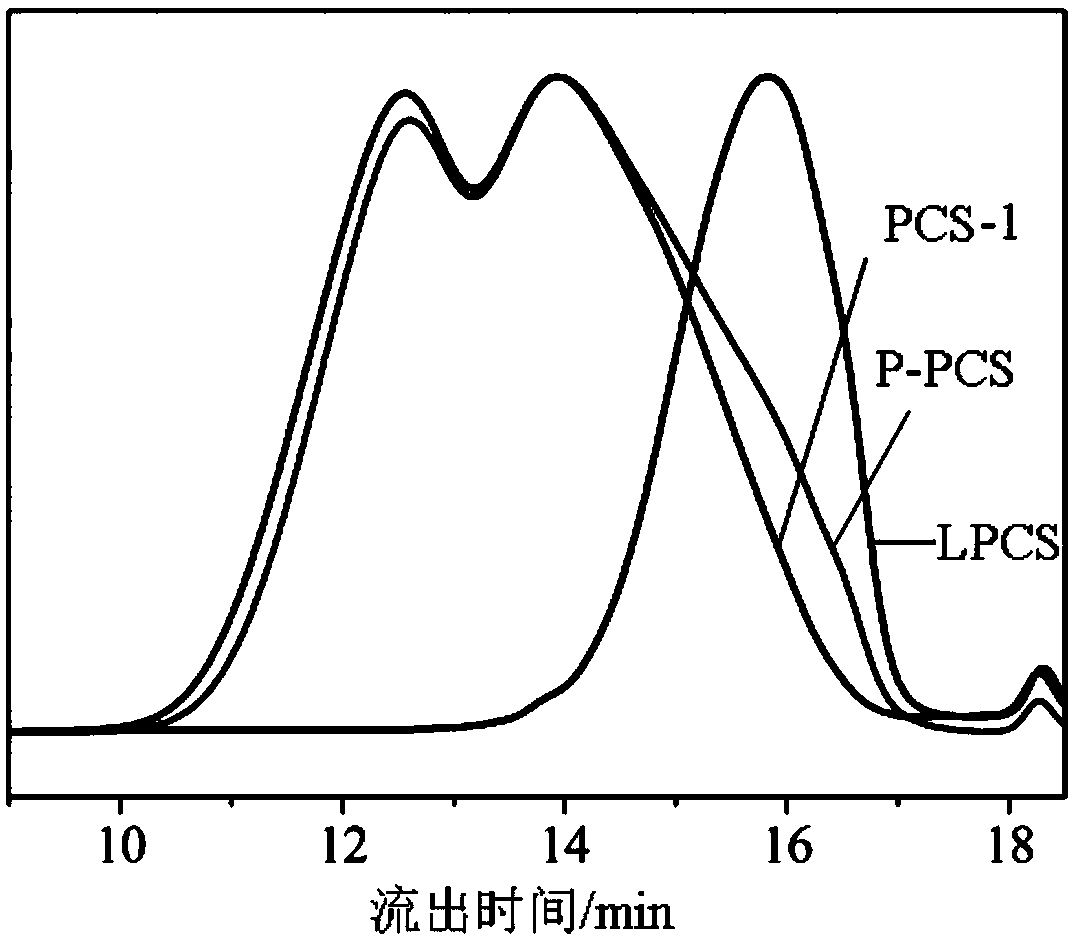

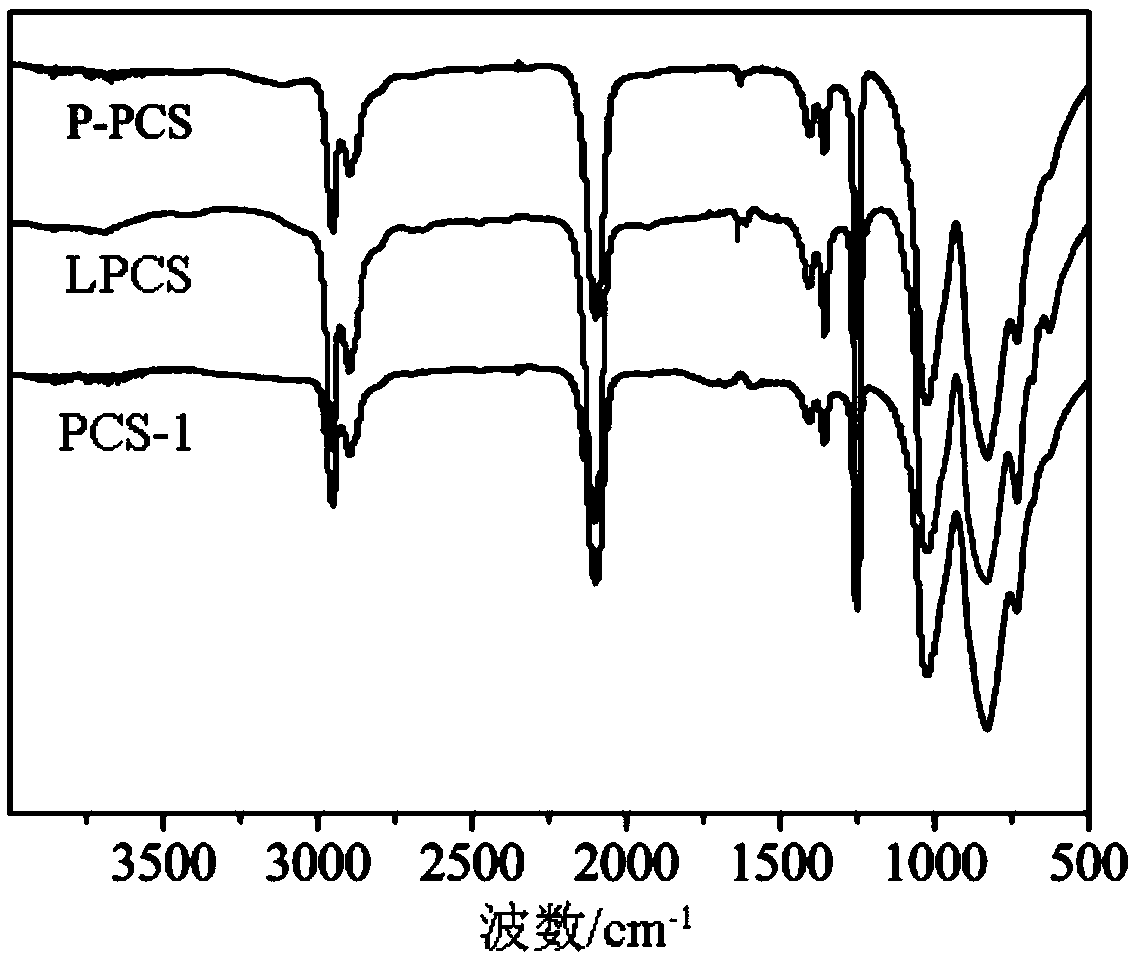

[0044] (2) Dissolve the P-PCS obtained in step (1) with 200ml of xylene, filter and distill, distill at 350°C for 1 hour to remove the xylene, and distill at 350°C for 1 hour to obtain the product PCS and the distilled LPCS, PCS The yield is 50%, the PCS at this time is named as PCS-1, and the LPCS is named as LPCS-1;

[0045] (3) LPCS is recovered and mixed with 360g PDMS, and steps (1) and (2) are repeated;

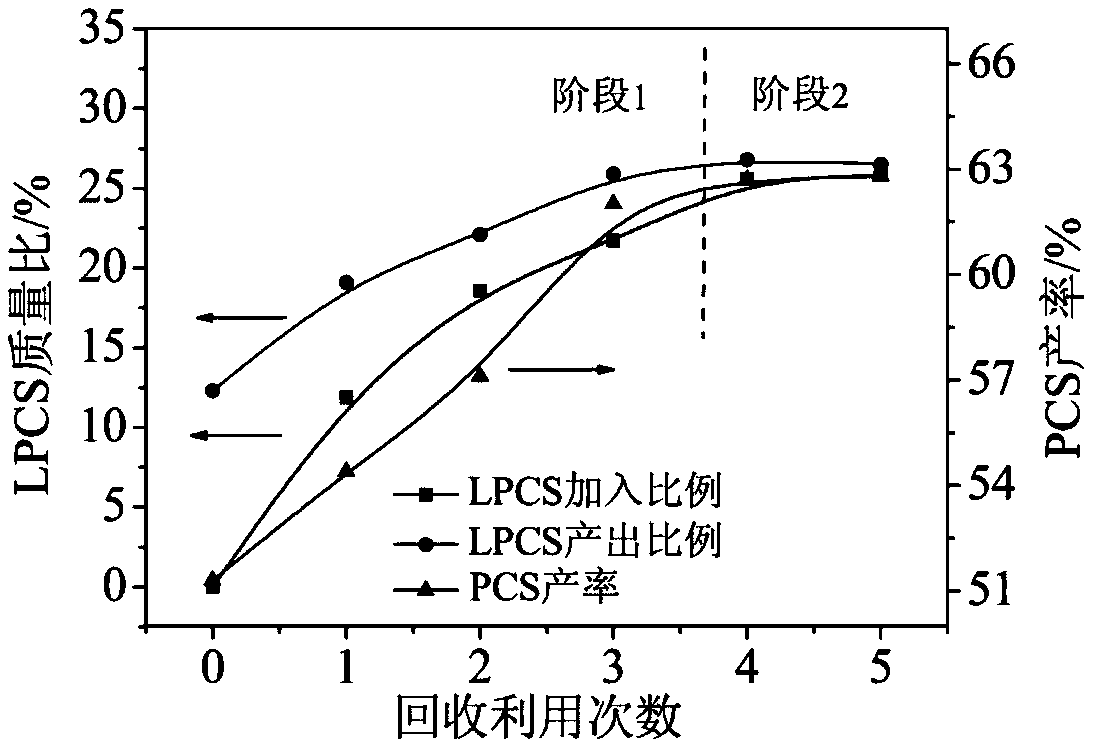

[0046] (4) When the process of preparing PCS was repeated to the 6th time, the amount of LPCS added was 94g, and the gained LPCS was 94g equally. At this time, the yield of PCS was 63%. The PCS at this time was named PCS-6, LPCS Named LPCS-6.

[0047] see figure 1 , wherein the process of preparing PCS with PDMS as a raw material for the first synthesis of PCS can be regard...

Embodiment 3

[0054] (1) Put 360g of PDMS in a three-necked flask, raise the temperature to 480°C for 8 hours under the protection of nitrogen, and carry out pyrolysis rearrangement reaction to prepare P-PCS;

[0055] (2) Dissolve the P-PCS obtained in step (1) with 200ml of xylene, filter and distill, distill at 350°C for 1 hour to remove the xylene, and distill at 350°C for 1 hour to obtain the product PCS and the distilled LPCS, PCS The yield is 57%;

[0056] (3) LPCS is recovered and mixed with 360g PDMS, and steps (1) and (2) are repeated;

[0057] (4) When the process of preparing PCS was repeated for the fourth time, the amount of LPCS added was 50 g, and the recovered LPCS was also 50 g, and the yield of PCS was 65%.

[0058] The process of using PDMS as raw material to synthesize PCS for the first time can be regarded as the traditional method for synthesizing PCS. In contrast, the yield of PCS is increased from 57% to 65%.

[0059] The yield of PCS can be stabilized at 63% with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com