Leakage preventive hydrogen tank for hydrogen-powered automobile

A technology for power vehicles and hydrogen tanks, which is applied to fixed-capacity gas storage tanks, pressure vessels, and outer walls of container structures, and can solve problems such as potential safety hazards and leakage during the use of hydrogen tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

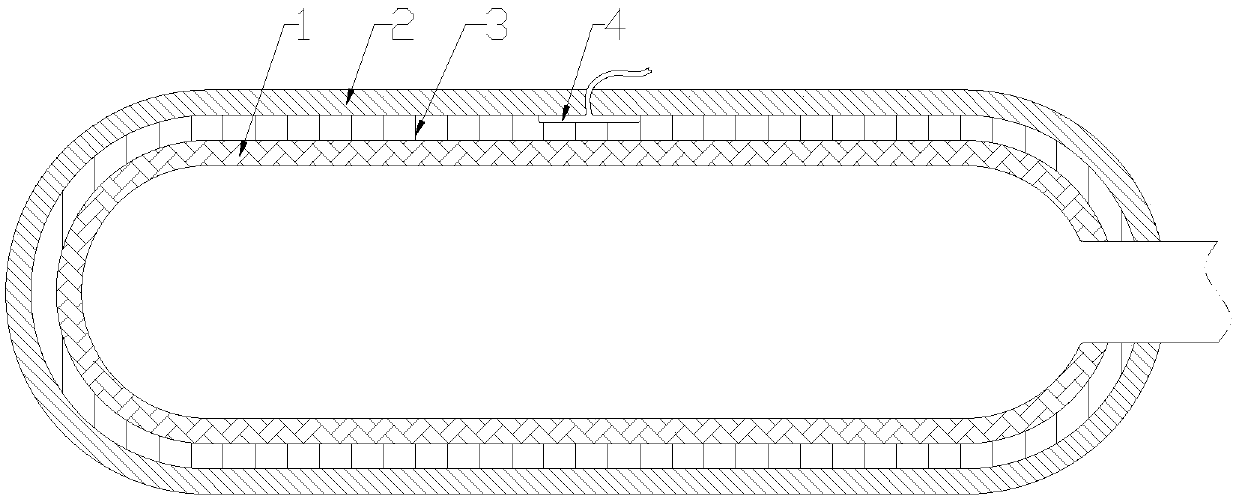

[0018] Such as figure 1 Shown is the first specific embodiment of the present invention, a leak-proof hydrogen tank for hydrogen-powered vehicles, including a hydrogen tank inner layer 1 and a hydrogen tank outer layer 2, and the hydrogen tank inner layer 1 is reinforced by carbon fiber from outside to inside Composed of a resin layer and a resin lining, the outer layer 2 of the hydrogen tank is composed of a glass fiber reinforced resin layer, a carbon fiber reinforced resin layer and a resin lining in sequence from the outside to the inside, and a cavity is formed between the inner layer 1 of the hydrogen tank and the outer layer 2 of the hydrogen tank, A leak-proof hydrogen tank for a hydrogen-powered vehicle also includes a solid hydrogen storage material 3 and a hydrogen leakage detection device 4 arranged in the cavity between the inner layer 1 of the hydrogen tank and the outer layer 2 of the hydrogen tank, and a data receiving and processing system, The hydrogen leakag...

no. 2 Embodiment

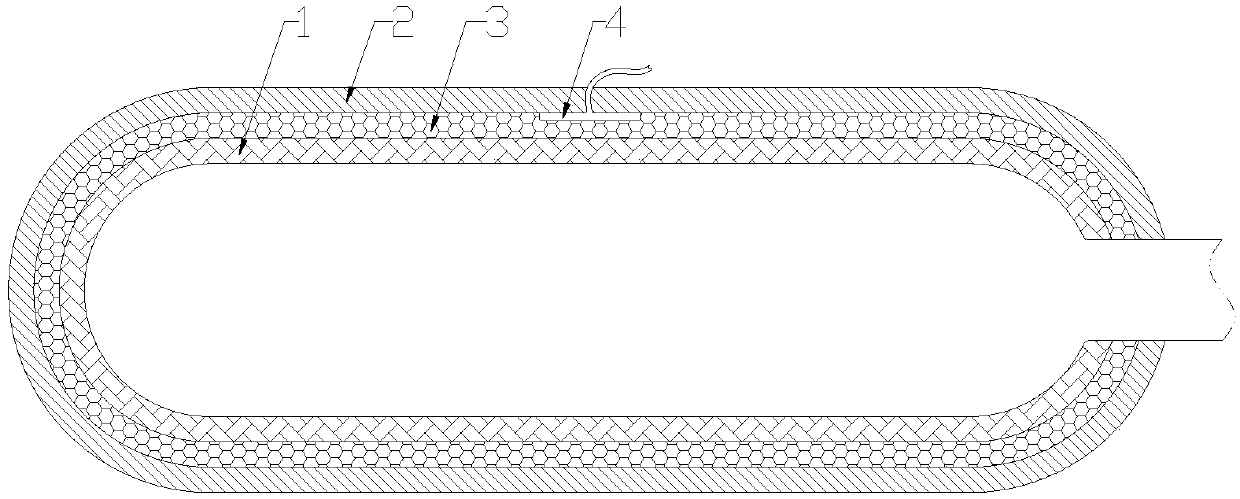

[0020] Such as figure 2 Shown is the second specific embodiment of the present invention, a leak-proof hydrogen tank for hydrogen-powered vehicles, a leak-proof hydrogen tank for hydrogen-powered vehicles, including a hydrogen tank inner layer 1 and a hydrogen tank outer layer 2, The inner layer 1 of the hydrogen tank is composed of a carbon fiber reinforced resin layer and a resin lining in sequence from the outside to the inside. The outer layer 2 of the hydrogen tank is composed of a glass fiber reinforced resin layer, a carbon fiber reinforced resin layer and a resin lining in sequence from the outside to the inside. The inner layer of the hydrogen tank 1 and A cavity is formed between the outer layers 2 of the hydrogen tank, and a leak-proof hydrogen tank for a hydrogen-powered vehicle also includes a solid hydrogen storage material 3 and The hydrogen leakage detection device 4 and the data receiving and processing system, the hydrogen leakage detection device 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com