Method used for measuring content of lysinoalanine in whey protein

A determination method, whey protein technology, applied in the field of food processing, can solve the problems of no unified determination method of lysalanine content, etc., achieve the effect of reducing interference, improving accuracy and lowering detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] All reagents (unless otherwise specified) were from Shanghai Aladdin Reagent Company, China, and HPLC grade solvents were provided by Fisher Technology Chemicals, UK.

[0043] LL-LAL and LD-LAL Mixed Standards Swiss Bachem Company

[0044] Chloroformic acid-9-fluorenylmethyl ester (FMOC-Cl) Switzerland Bachem company

[0045] Amino acid solid phase extraction cartridge (3cc / 500mg) American waters company

[0046] The pH of 0.4mol / L, 0.2mol / L and 0.1mol / L borate buffer was adjusted to 12, 9.0 and 7.2 with 6mol / L NaOH, respectively.

[0047] FMOC-Cl derivative agent: Dissolve appropriate amount of FMOC-Cl in acetonitrile to make the concentration reach 5mg / mL.

[0048] SPE Activation Solution: Mix acetonitrile and 0.1mol / L borate buffer (pH=7.2) at a volume ratio of 1:4.

[0049] SPE eluent 1: Mix acetonitrile and water at a volume ratio of 1:4.

[0050] SPE eluent 2: Mix acetonitrile and water at a volume ratio of 1:1.

[0051] SPE eluent: acetonitrile and 0.2mol / L ...

Embodiment 2

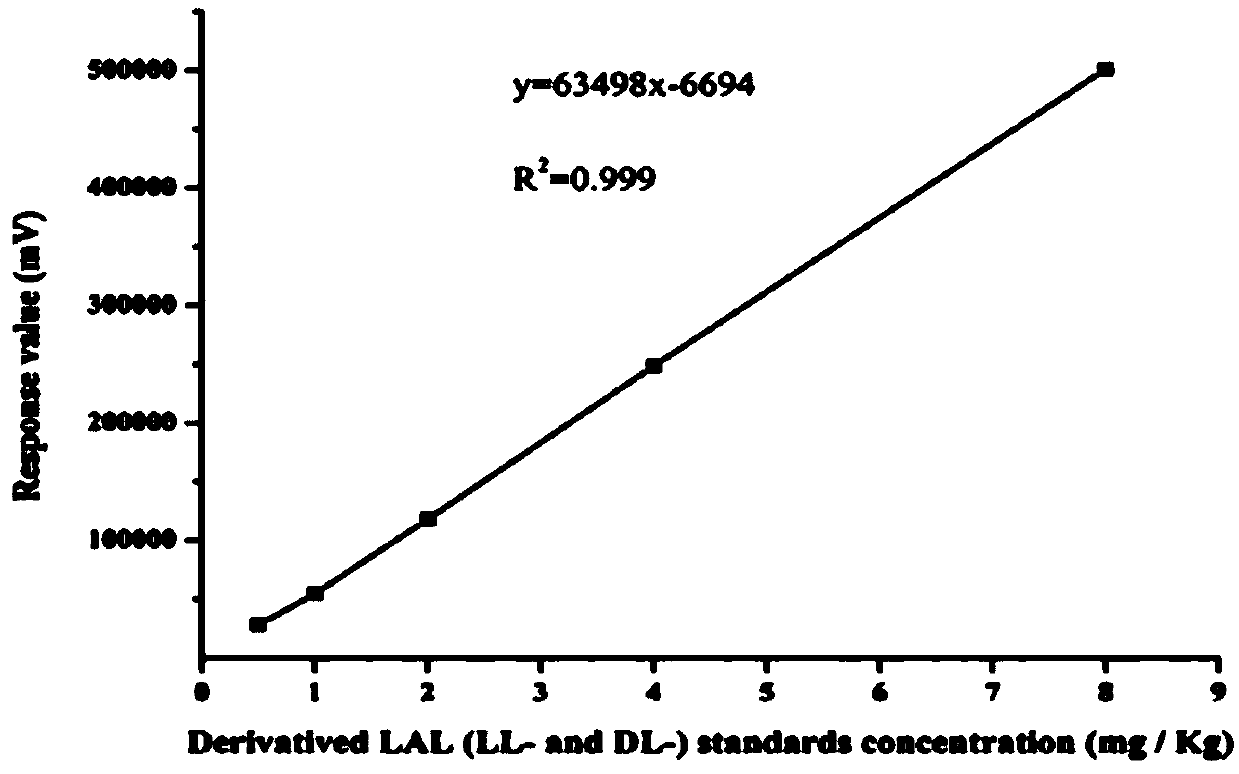

[0065] 1. Drawing of standard curve

[0066] Concentrations of 0.5, 1, 2, 4, 8mg / Kg standards (LL-LAL and LD-LAL mixed standard) are prepared, and the pretreatment method is exactly the same as that of the sample to be tested, including hydrolysis, derivatization, and solid phase extraction. According to the method shown in the present invention, the response values of different concentrations of standard derivatives are determined by reversed-phase high performance liquid chromatography, and the standard curve is drawn with the concentration of standard derivatives as the abscissa and the response value as the ordinate. Such as figure 1 shown.

[0067] The results show that the peak area response value of HPLC is linear when the LAL standard substance concentration is 0.5-8mg / Kg (r 2 =0.999), indicating that the measuring instrument has good repeatability.

Embodiment 3

[0069] 2. Measurement of precision, accuracy and reproducibility

[0070] Precision refers to the closeness between the results of the same sample to be tested after multiple sampling measurements, and is generally expressed by relative standard deviation (RSD). Add an equal volume of 4mg / Kg LAL standard substance to deionized water (blank control) without any LAL, after a series of pretreatment methods such as acid hydrolysis, derivatization, solid phase extraction, etc., repeat 9 times to measure its LAL The precision was expressed by calculating the RSD values of retention time and peak area.

[0071] Accuracy refers to the closeness between the measured value of the sample measured by the above method and the true value, which can usually be expressed by the recovery rate. The accuracy is expressed by adding equal volumes of 0, 0.5, 2, and 8 mg / Kg LAL standard substances to the sample to be tested, and calculating the recovery rate and the RSD value of the peak area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com