Method for measuring phthalates in flavors and fragrances for tobaccos

A technology of phthalates and tobacco flavors, applied in the field of tobacco flavors and fragrances (liquid field, can solve the problems of no impurity removal step, obvious matrix effect, pollution of analytical column and ion source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

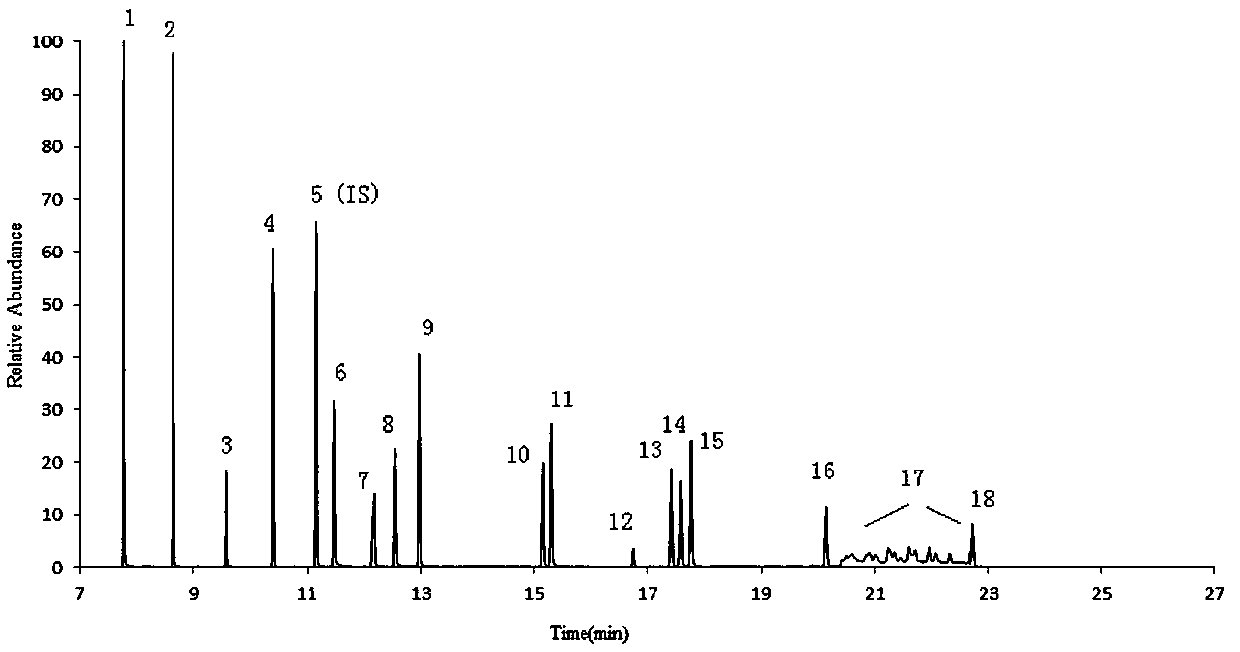

[0049] Example: Determination of phthalates in tobacco flavor and fragrance samples.

[0050] (1) Pre-processing

[0051] Weigh 0.3-0.6g of flavor and fragrance samples into a 25 mL Erlenmeyer flask with a stopper, accurate to 0.0001 g, add 7-15 mL of ethanol aqueous solution (volume ratio 1:1), and then add 250 µL of internal standard solution (solvent is ethanol, Concentration is 0.1 mg / mL), ultrasonic extraction for 30min, take 2mL initial extraction solution into 15mL glass centrifuge tube, add 5mL n-hexane / ethyl acetate / isopropanol solution (volume ratio is 3:1:1), at 2000 Vortex and oscillate at rpm for 5 min, then centrifuge at 4000 rpm for 5 min, and take the supernatant for testing.

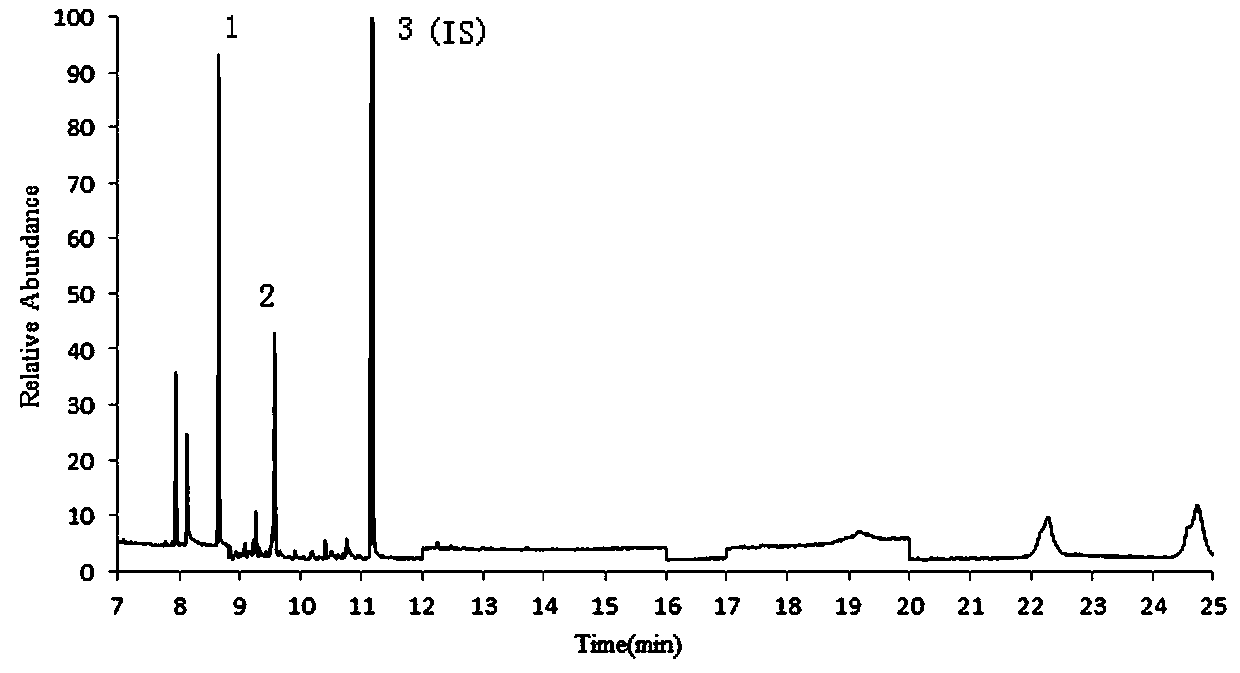

[0052] (2) Blank experiment

[0053] Repeat step (1) without adding sample.

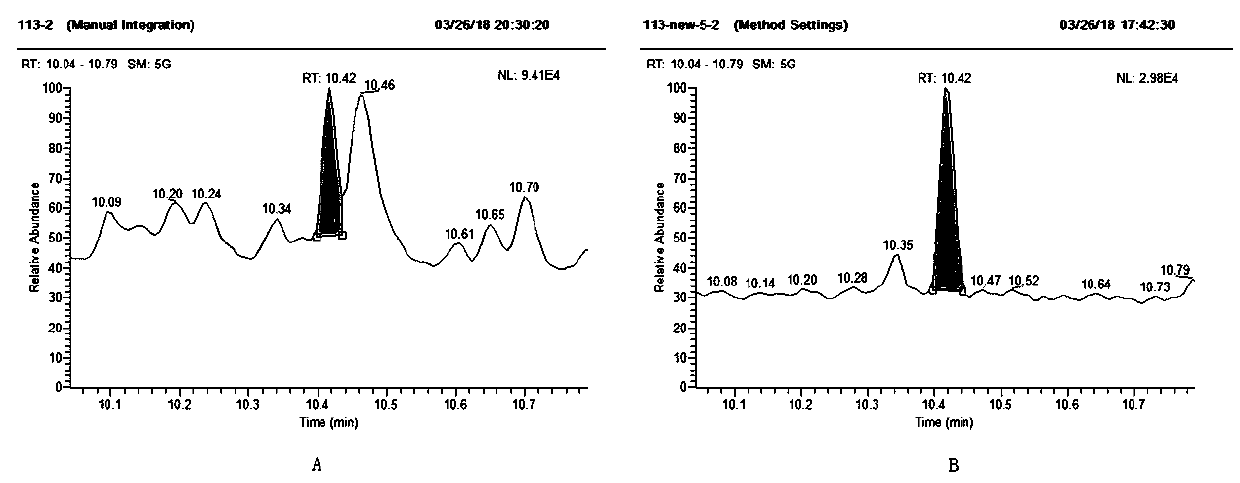

[0054] (3) Instrument analysis

[0055] It was measured by GC-MS, and the measurement conditions were as follows.

[0056] Gas chromatography conditions:

[0057] Column stationary phase: 5% phenyl / 95% me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| ion source temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com