Coke oven flue gas low-temperature SCR denitration and waste heat recycling integrated device and process

A coke oven flue gas and waste heat recovery technology, applied in gas treatment, lighting and heating equipment, process efficiency improvement and other directions, can solve problems such as blockage of heat exchangers, anticorrosion of original chimneys, deactivation of catalysts, etc. , avoid anti-corrosion transformation, the effect of low flue gas leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

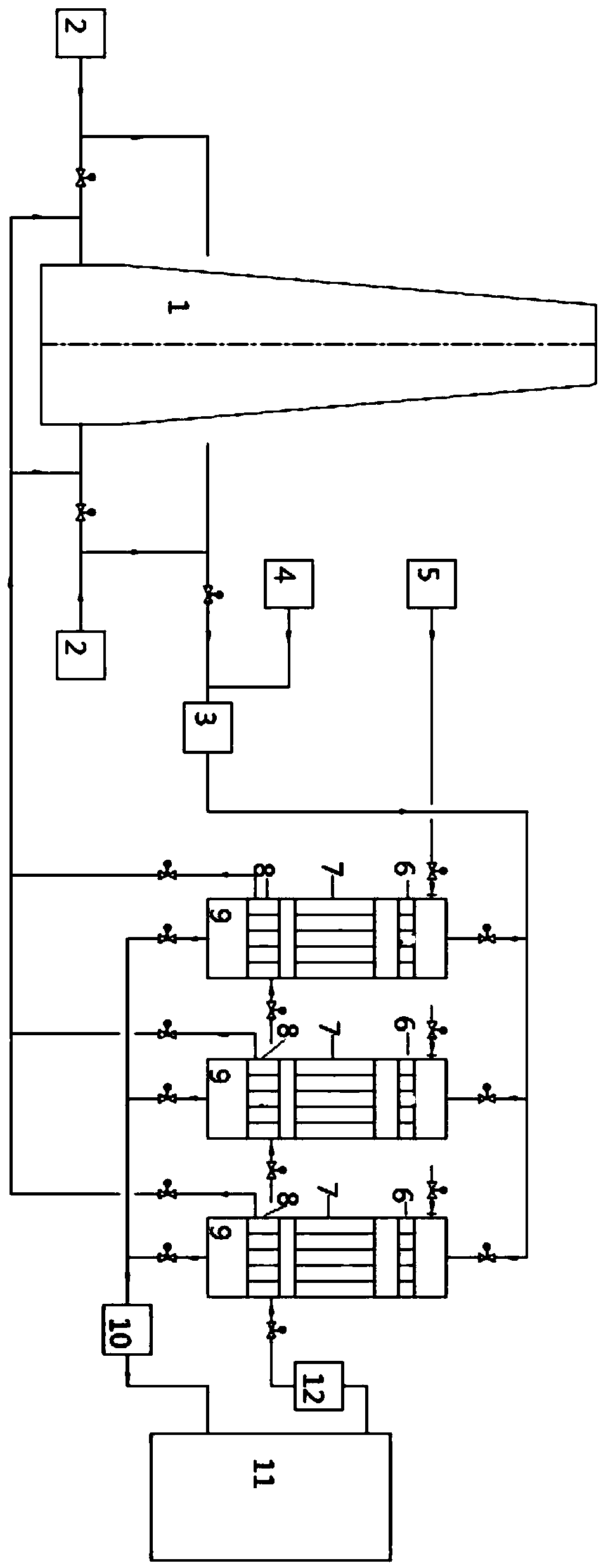

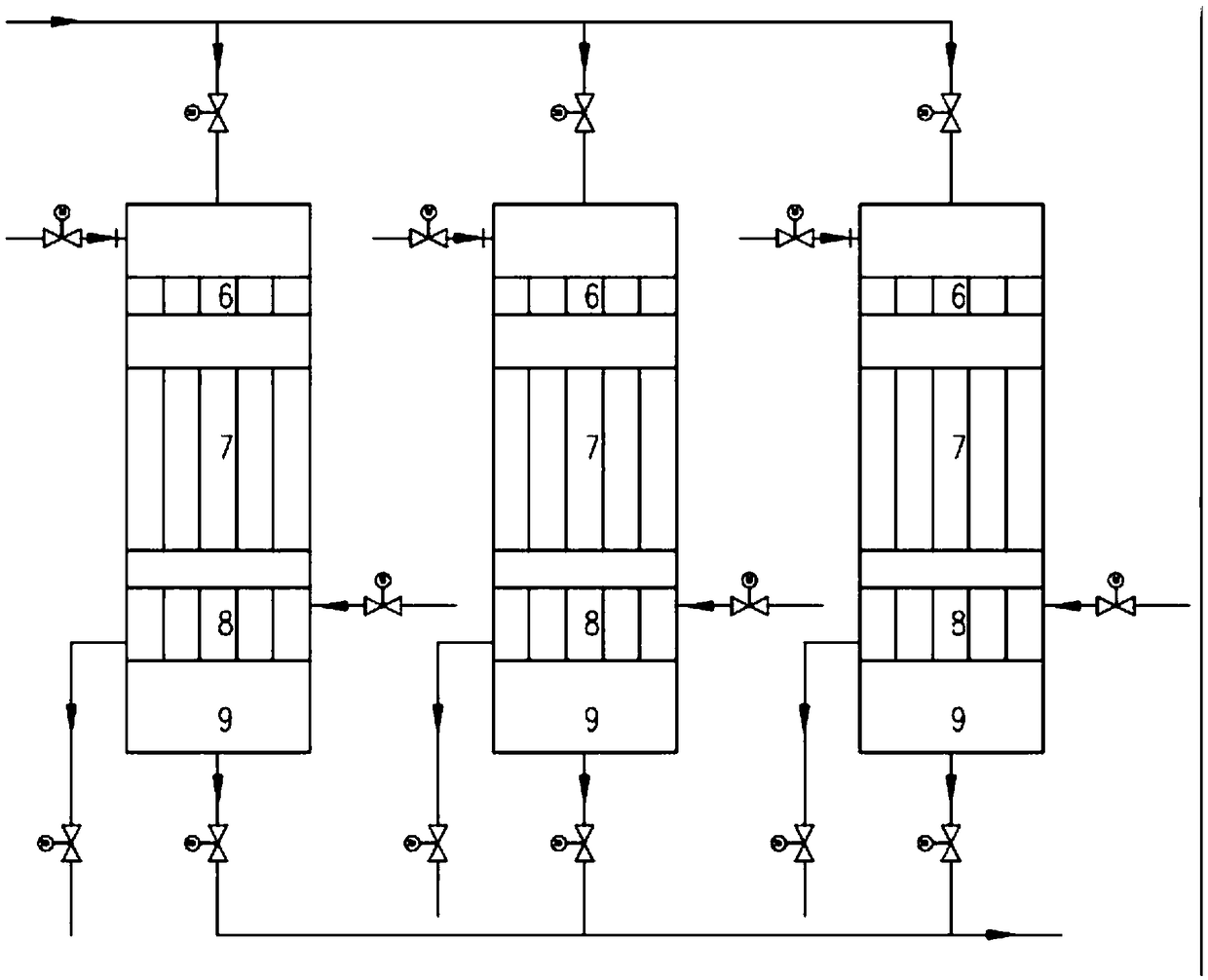

[0039] This embodiment provides a sub-bin type low-temperature SCR denitration process in which coke oven flue gas is returned to the original chimney and discharged. The coke oven flue gas removes the tar in the flue gas before entering the low-temperature SCR denitration catalyst, removes the nitrogen oxides in the flue gas through the SCR reaction, reduces the temperature through the flue gas heat exchanger, and enters the subsequent desulfurization and dust removal system. The final purification process The flue gas enters the flue gas heat exchanger and is heated to above 140°C, enters the original chimney and is discharged, and finally meets the ultra-low emission transformation requirements of the iron and steel enterprise, including the underground flue 2, ammonia gasification device, and denitration reaction connected to the coke oven chimney 1 in sequence The ammonia gasification device includes the ammonia gasifier 3 and the burner 4 arranged in the main flue, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap