Light irradiation apparatus

A technology of light irradiation device and object to be treated, applied in the direction of cleaning flexible articles, electrical components, semiconductor/solid-state device manufacturing, etc. The effect of cleaning, improving airtightness, and suppressing the attenuation of ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

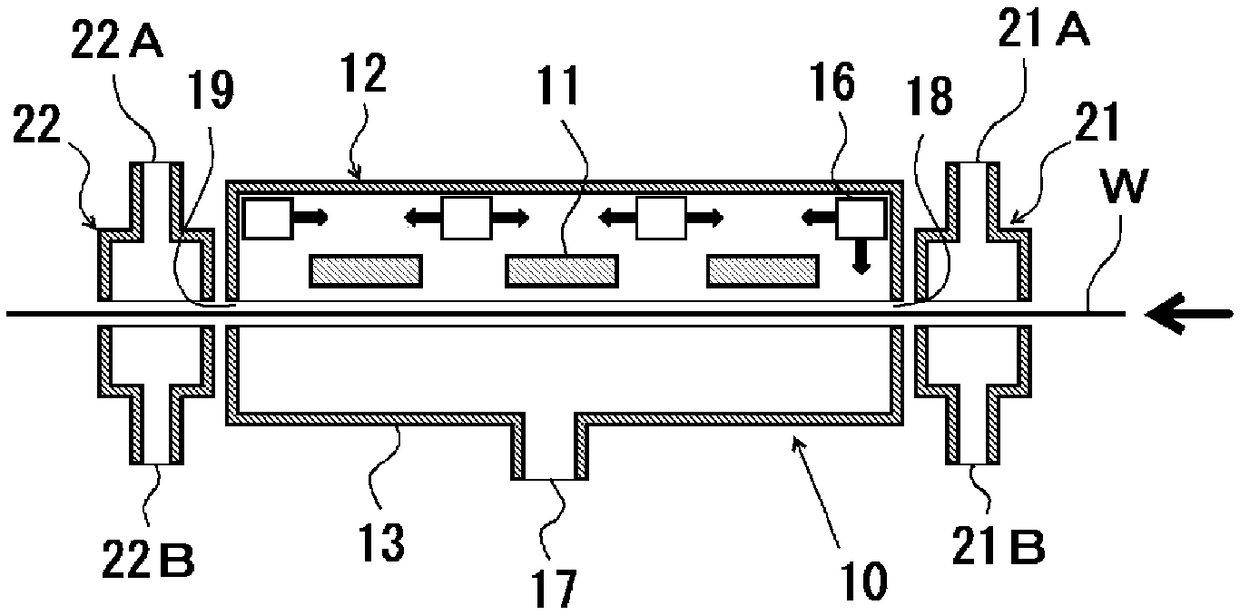

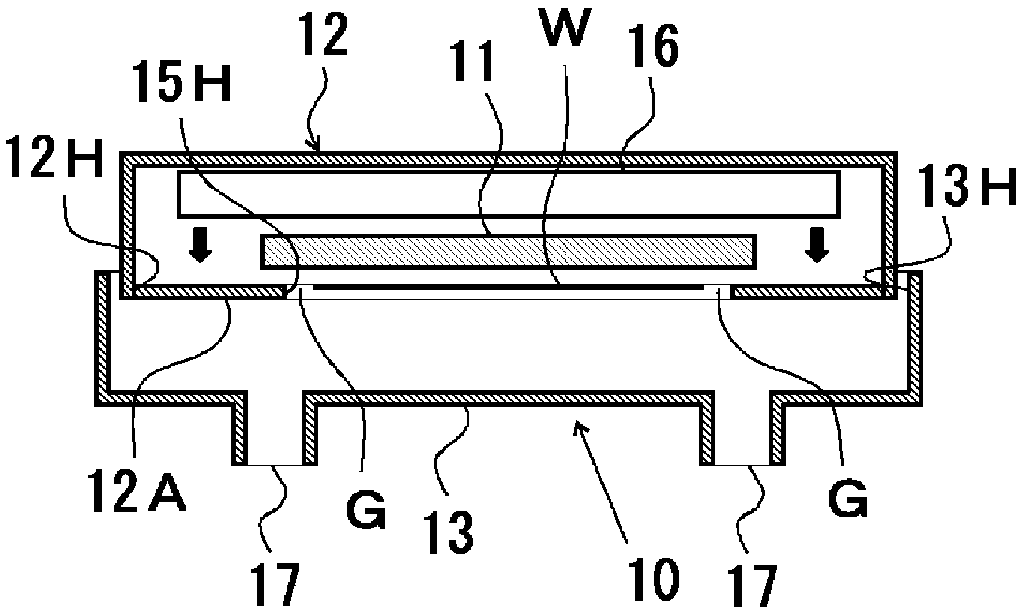

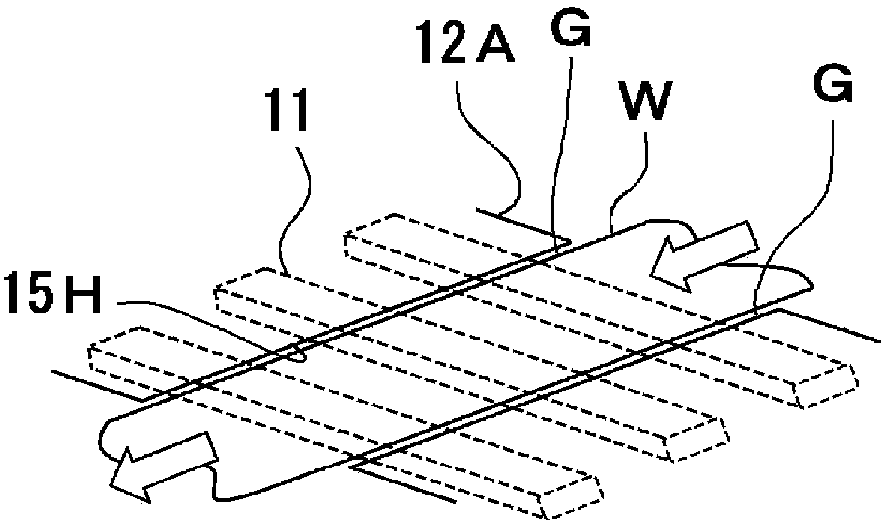

[0125] Made with Figure 1 ~ Figure 3 The structure of the light irradiation device [1]. Specifically, it is as follows.

[0126] Processing chamber; length of the object to be processed in the conveying direction: 445 mm, length of the object to be processed in the width direction: 1090 mm, distance between the processing area and the top surface of the lampshade: 72 mm, distance between the processing area and the exhaust space forming member The distance between the bases: 150mm, the distance (interval) of the narrow passage for gas flow resistance: 10mm

[0127] Ultraviolet lamp; type: xenon excimer lamp, center wavelength: 172nm, length: 640mm, effective irradiation width: 510mm, distance from the treatment area: 4mm

[0128] ・Pressure inside the lampshade: Positive pressure 2 Pa higher than the external atmosphere (atmospheric pressure)

[0129] ・Pressure inside the exhaust space forming member: Negative pressure 2 Pa lower than the external atmosphere (atmospheric pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com