Anticorrosive and antibacterial medium-density fiber plate and manufacturing process thereof

A technology of anti-corrosion and anti-bacterial, anti-corrosion and anti-bacterial agent, applied in the direction of manufacturing tools, flat products, wood processing equipment, etc., can solve the problems of man-made fiberboards, such as easy to decay, insects, mildew, etc. The effect of less drug loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

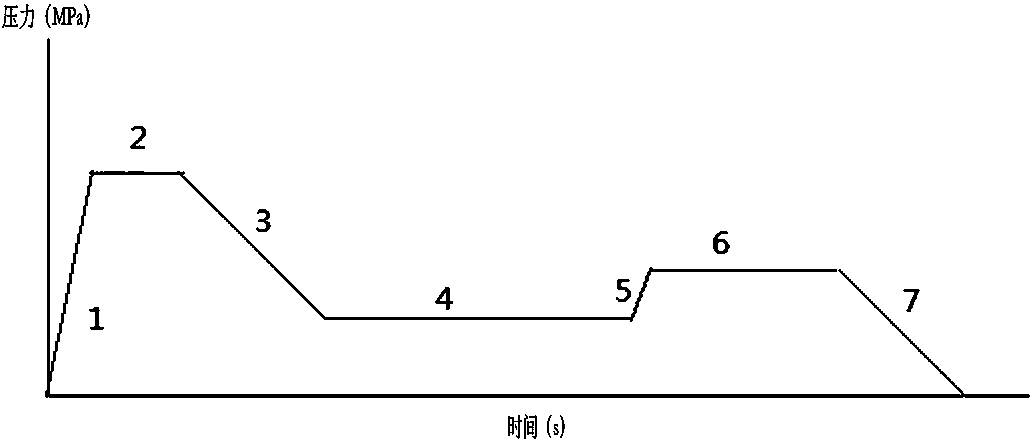

Image

Examples

Embodiment 1

[0035] An antiseptic and antibacterial fiberboard is composed of wood fiber, adhesive, antiseptic and antibacterial agent and paraffin, and the percentage of each raw material in dry wood fiber is as follows:

[0036] Adhesive 10%, of which isocyanate 50%, E0 grade urea-formaldehyde resin 50%;

[0037] Antiseptic antibacterial agent A 0.25%, of which ethanolamine copper 60%, didecyldimethyl ammonium chloride 40%;

[0038] Antiseptic and antibacterial agent B 0.3%, that is, boric acid 0.3%;

[0039] Emulsified paraffin 1%;

[0040] Wood fiber, 100%, including 20% ginkgo wood fiber and 80% poplar wood fiber.

[0041] The process for making the above-mentioned anti-corrosion and anti-bacterial fiberboard includes the following steps:

[0042] A. Preparation of antiseptic and antibacterial agent: put ethanolamine copper and didecyldimethylammonium chloride into water at 40-45°C in proportion, stir until dissolved, and make antiseptic and antibacterial agent A with 1% active i...

Embodiment 2

[0051] An antiseptic and antibacterial fiberboard is composed of wood fiber, adhesive, antiseptic and antibacterial agent and paraffin, and the percentage of each raw material in dry wood fiber is as follows:

[0052] Adhesive 12%, of which isocyanate 55%, E0 grade urea-formaldehyde resin 45%;

[0053] Antiseptic antibacterial agent A 0.25%, of which ethanolamine copper 65%, didecyldimethylammonium chloride 35%;

[0054] Antiseptic and antibacterial agent B 0.5%, that is, boric acid 0.5%;

[0055] Emulsified paraffin 1%;

[0056] Wood fiber, 100%, including 25% ginkgo wood fiber and 75% poplar wood fiber.

[0057] The process for making the above-mentioned anti-corrosion and anti-bacterial fiberboard includes the following steps:

[0058] A. Preparation of antiseptic and antibacterial agent: put ethanolamine copper and didecyldimethylammonium chloride into water at 40-45°C in proportion, stir until dissolved, and make antiseptic and antibacterial agent A with 1% active ingr...

Embodiment 3

[0067] An antiseptic and antibacterial fiberboard is composed of wood fiber, adhesive, antiseptic and antibacterial agent and paraffin, and the percentage of each raw material in dry wood fiber is as follows:

[0068] Adhesive 11%, of which isocyanate 60%, E0 grade urea-formaldehyde resin 40%;

[0069] Antiseptic antibacterial agent A 0.5%, of which ethanolamine copper 70%, didecyldimethylammonium chloride 30%;

[0070] Antiseptic and antibacterial agent B 0.3%, that is, boric acid 0.3%;

[0071] Emulsified paraffin 1%;

[0072] Wood fiber, 100%, including 15% ginkgo wood fiber and 85% poplar wood fiber.

[0073] The process for making the above-mentioned anti-corrosion and anti-bacterial fiberboard includes the following steps:

[0074] A. Preparation of antiseptic and antibacterial agent: put ethanolamine copper and didecyldimethylammonium chloride into water at 40-45°C in proportion, stir until dissolved, and make antiseptic and antibacterial agent A with 1.5% active ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com