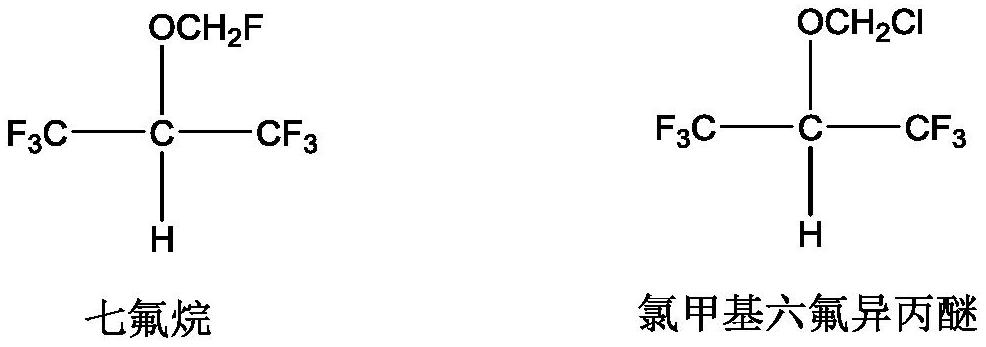

A kind of preparation method of chloromethyl hexafluoroisopropyl ether

A technology of chloromethyl hexafluoroisopropyl ether and hexafluoroisopropyl alcohol, which is applied in the field of preparation of chloromethyl hexafluoroisopropyl ether, can solve the problem that it is not suitable for industrial production, cannot meet industrial production, and the final product contains a large amount of impurities and other problems, to achieve the effect of solving the curing phenomenon, reducing the difficulty of purification, and reducing the content of acetal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 310kg of aluminum trichloride and 210kg of chloromethyl hexafluoroisopropyl ether into a 1000L reactor, cool down to -5°C to 0°C, add 300kg of hexafluoroisopropanol dropwise under stirring, and continue stirring for 0.5 Hour, add 56.8kg paraformaldehyde again, reaction temperature is lower than 35 ℃, continue to react for 17 hours. Lower the temperature below 0°C, add 600L of 6mol / L hydrochloric acid dropwise, and the temperature during the dropwise addition of hydrochloric acid should not exceed 15°C. The organic layer was separated and washed twice with 600 L of water to obtain 352.0 kg of chloromethyl hexafluoroisopropyl ether with a GC purity of 99.1% (the acetal impurity content was 0.8%) and a yield of 91.1%.

Embodiment 2

[0026] In a 1000L reactor, add 450kg sulfolane, 105kg potassium fluoride and 30kg pentaerythritol, then add 140kg chloromethyl hexafluoroisopropyl ether and 25kg purified water. Heated, reacted at 97-102°C for 10 hours, cooled down, added 150kg of purified water, distilled to obtain 105.0kg of crude sevoflurane, rectified to obtain 64.0kg of sevoflurane finished product, GC purity 99.991%.

Embodiment 3

[0027] Embodiment 3: according to US6100434 method

[0028] Add 50kg of aluminum trichloride to a 200L reactor, cool down to -5°C to 0°C, add 63kg of hexafluoroisopropanol dropwise under stirring, continue stirring for 0.5 hours after dropping, then add 12kg of paraformaldehyde, the reaction temperature Below 35°C, the reaction was continued for 17 hours. Lower the temperature below 0°C, add 100L of 6mol / l hydrochloric acid dropwise (solidification occurs during the process), and the temperature during the dropwise addition of hydrochloric acid should not exceed 15°C. The lower organic layer was washed twice with 100 L of water to obtain 69.9 kg of chloride with a GC purity of 87.0% (the acetal impurity content was 12%) and a yield of 86.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com