Method for recovering copper, nickel and chromium in electroplating sludge

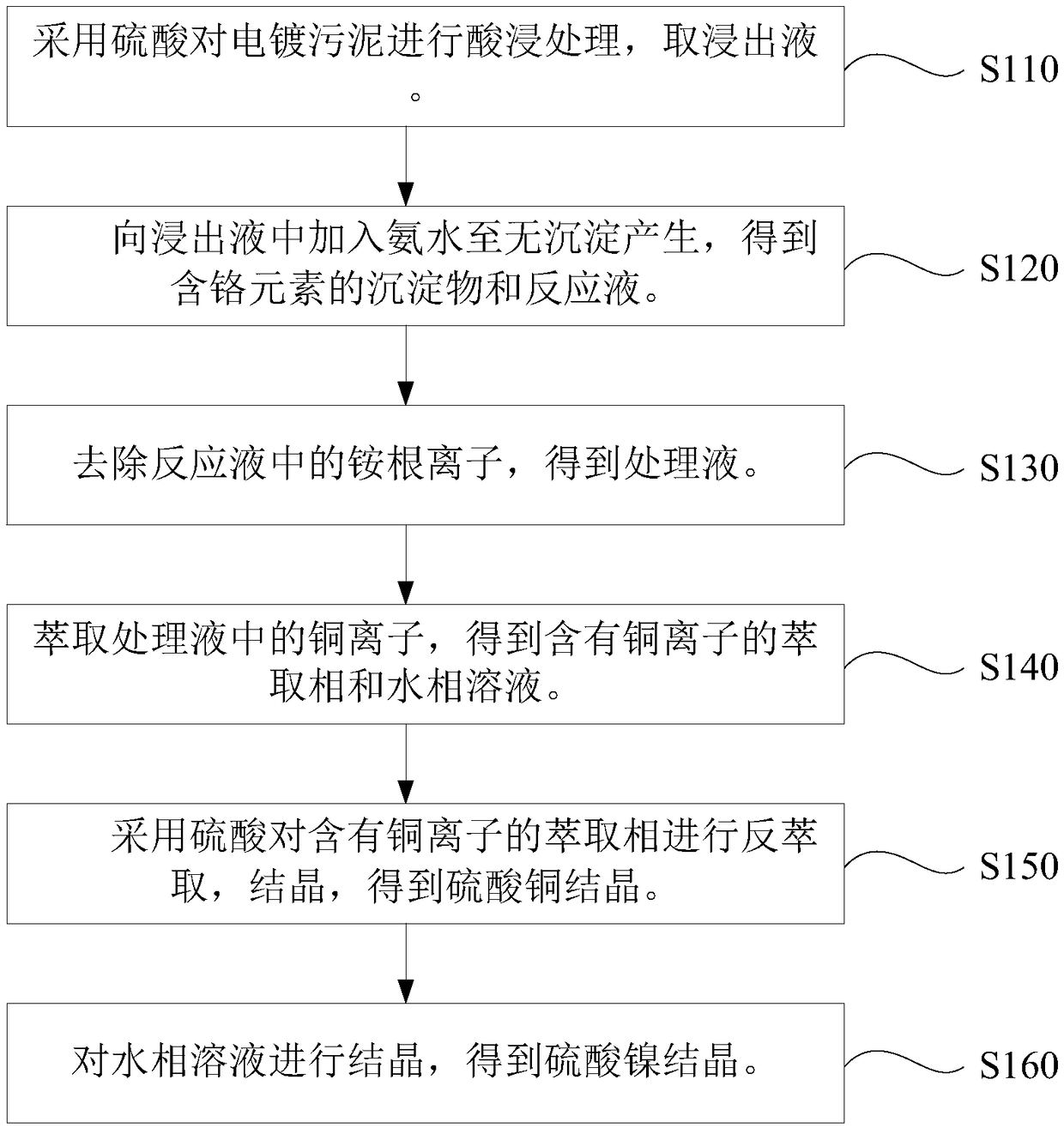

A technology of electroplating sludge and recovery method, which is applied to the recovery of chromium, nickel and copper, can solve the problems of low recovery rate, high energy consumption, and cannot be reused, and achieves the effect of high recovery rate and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The recovery steps of copper, nickel and chromium in the electroplating sludge of the present embodiment are as follows:

[0063] 1) Under normal temperature conditions, add sulfuric acid with a concentration of 5% by mass to the electroplating sludge with a water content of 80% to make the pH of the electroplating sludge 1.0, perform secondary countercurrent leaching for 3 hours, and press filter , to obtain leachate and filter residue, wherein the mesh number of the filter screen is 60 mesh; then the filter residue is repeatedly washed 3 times with tap water, and press-filtered 4 times for harmless treatment.

[0064] 2) Under the conditions of normal temperature and 0.01MPa, add ammonia water with a mass percentage concentration of 25% to the leachate to make it alkaline, react for 3.5 hours, and filter to obtain chromium hydroxide precipitate and reaction solution, wherein the mesh size of the filter screen is It is 150 mesh.

[0065] 3) Under the conditions of 0.0...

Embodiment 2

[0071] The recovery steps of copper, nickel and chromium in the electroplating sludge of the present embodiment are as follows:

[0072] 1) Under normal temperature conditions, add sulfuric acid with a concentration of 15% by mass to the electroplating sludge with a water content of 80% to make the pH of the electroplating sludge 1.0, perform secondary countercurrent leaching for 4 hours, and press filter , to obtain leachate and filter residue, wherein the mesh number of the filter screen is 60 mesh; then the filter residue is repeatedly washed 3 times with tap water, and press-filtered 4 times for harmless treatment.

[0073] 2) Under the conditions of normal temperature and 0.03MPa, add ammonia water with a mass percentage concentration of 25% to the leachate to make it alkaline, react for 3.5 hours, and filter to obtain chromium hydroxide precipitate and reaction solution, wherein the mesh size of the filter screen is It is 160 mesh.

[0074] 3) Under the conditions of 0....

Embodiment 3

[0080] The recovery steps of copper, nickel and chromium in the electroplating sludge of the present embodiment are as follows:

[0081] 1) Under normal temperature conditions, add sulfuric acid with a mass percentage concentration of 15% to the electroplating sludge with a water content of 80% to make the pH value of the electroplating sludge 1.0, carry out secondary countercurrent leaching for 3.5 hours, press Filter to obtain leachate and filter residue, wherein the mesh number of the filter screen is 50 mesh; then the filter residue is repeatedly washed 3 times with tap water, and press-filtered 4 times for harmless treatment.

[0082] 2) Under the conditions of normal temperature and 0.03MPa, add ammonia water with a mass percentage concentration of 25% to the leachate to make it alkaline, react for 3.5 hours, and filter to obtain chromium hydroxide precipitate and reaction solution, wherein the mesh size of the filter screen is It is 160 mesh.

[0083] 3) Under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com