Method for high-carbon steel casting blank dendritic crystal corrosion and measurement

A high-carbon steel and slab technology, which is applied in the field of high-carbon steel slab dendrite corrosion and measurement, can solve the problems of dendrite structure damage, deep corrosion, and slab structure error, etc., to achieve clear dendrite structure and suppress The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

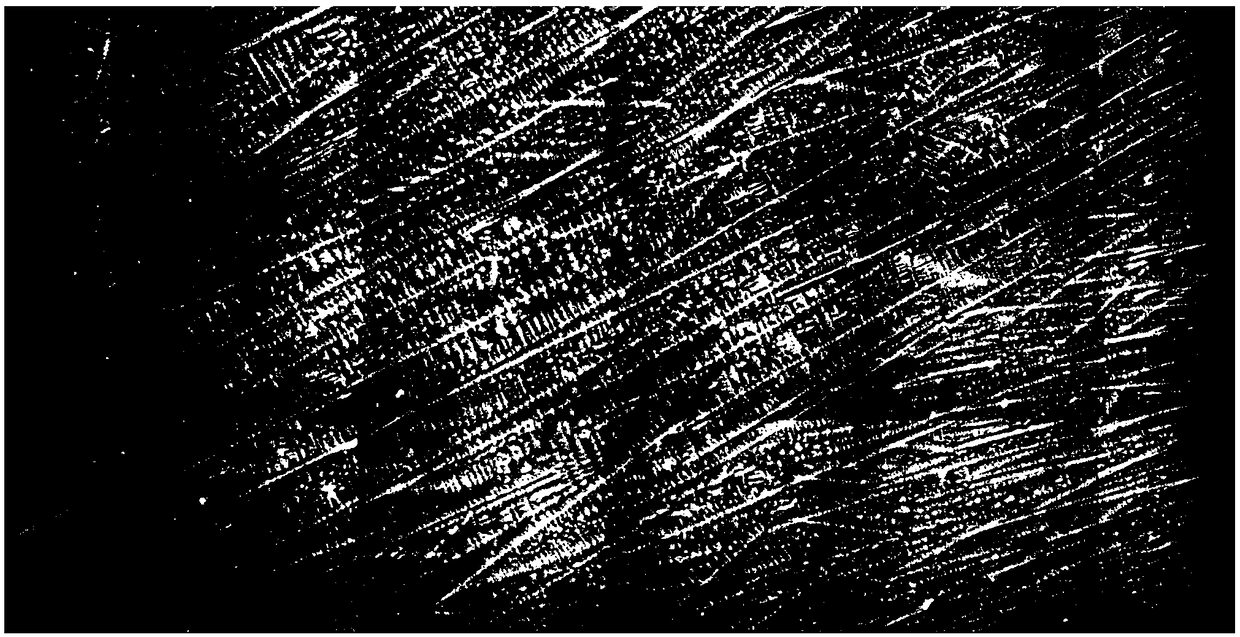

Image

Examples

Embodiment 1

[0019] The sample in the embodiment of the present invention, its chemical composition is C: 0.65%, Si: 0.8%, Mn: 0.5%, P: 0.015%, S: 0.020% high carbon steel continuous casting round billet sample, from the round billet Continuously cut samples with a length of 30 mm and a width of 20 mm from the surface layer to the radius of the core.

[0020] A method for dendrite corrosion and measurement of high carbon steel slab, comprising the following steps:

[0021] 1) Grind and polish the cross-section of the sample billet to a mirror surface according to the requirements of conventional metallographic inspection;

[0022] 2) Prepare a corrosive agent, dissolve picric acid and cuprous chloride in distilled water, then add detergent, stir and mix to obtain the product; the mass concentration of picric acid is 0.3%, and the mass concentration of cuprous chloride is 0.1%. The concentration of essence is 1%, and the balance is distilled water.

[0023] 3) Immerse the polished sample ...

Embodiment 2

[0026] The sample in the embodiment of the present invention, its chemical composition is C: 0.60%, Si: 0.75%, Mn: 0.55%, P: 0.013%, S: 0.015% high carbon steel continuous casting round billet sample, from the round billet Continuously cut samples with a length of 30 mm and a width of 20 mm from the surface layer to the radius of the core.

[0027] A method for dendrite corrosion and measurement of high carbon steel slab, comprising the following steps:

[0028] 1) Grind and polish the cross-section of the sample billet to a mirror surface according to the requirements of conventional metallographic inspection;

[0029] 2) Configure corrosive agent, dissolve picric acid and cuprous chloride in distilled water, then add detergent, stir and mix to get final product; the mass concentration of picric acid is 0.3%, the mass concentration of cuprous chloride is 0.15%, and the The concentration of essence is 1.5%, and the balance is distilled water.

[0030] 3) Immerse the polished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com