Four-wafer LED display lamp bead structure

A technology of LED display lights and chips, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of small LED size requirements, ordinary circuit boards cannot meet the needs of circuits at the same time, and the color gamut of three-primary-color LEDs cannot meet the requirements, etc. Achieve the effect of improving display color saturation, displaying brightness and vividness, and enhancing color fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

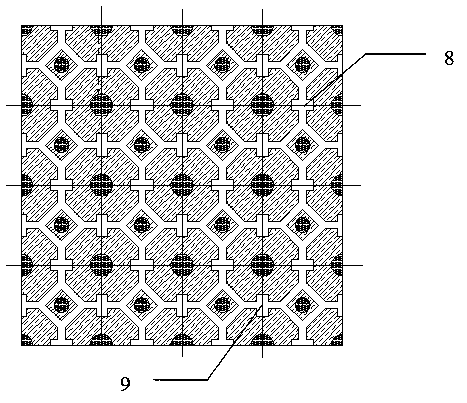

Embodiment 1

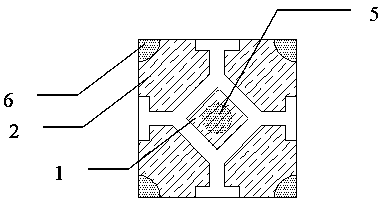

[0028] Image 6 Among them, the LED red chip 13 and the LED yellow chip 14 are bonded on two adjacent non-common level die bonding regions 2 in a vertical structure with conductive silver glue, and the LED blue chip 11 and the LED chip are bonded with insulating glue. The green chip 12 is bonded to the remaining two non-public die bonding areas 2 in a horizontal structure; the whole PCB with the chip fixed and the bonding wire bonded is put into a high-temperature molding mold, and resin is added, and the 150-220 tons of hydraulic pressure mold clamping, under the condition of 100-2220 ℃ mold temperature heating, the resin is initially cured, after the mold is opened, the semi-finished board that has been molded is taken out, baked in an environment of 130-200 ℃, so that the molded The resin is completely cured; transfer to the cutting process, fix it by sticking a film on the back of the semi-finished PCB, and start cutting according to the row cutting line 8 and column cutti...

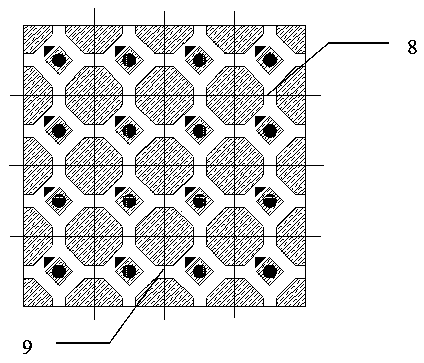

Embodiment 2

[0030] like Figure 7 As shown, the LED red chip 13 and the LED yellow chip 14 are bonded on the two non-common level die-bonding regions 2 at the diagonal with a vertical structure with conductive silver glue, and the LED blue chip 11 and the LED blue chip 11 are bonded with insulating glue. The LED green chip 12 is bonded on the remaining two non-common level die-bonding bonding regions 2 in a horizontal structure; other steps are the same as in Embodiment 1.

[0031] like Figure 8As shown, the four-crystal lamp bead arranged according to 2R1G1B splits one unit of four-crystal LED into four independent LED units. Each LED unit reproduces the corresponding primary color information of four adjacent pixels in a time-division multiplexing manner, and the LEDs are equally spaced and uniformly distributed among each other. Advantages The virtual pixel density is increased to 4 times; the effective visual pixel density can be increased by up to 4 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com