Beamsplitter for achieving grazing incidence of light

A technology of beam splitter and light incidence, which is applied in the field of optical systems, can solve the problems of increasing absorption loss, avoid layer degradation, reduce manufacturing effort and cost, and reduce the total number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Figure 12 Only a schematic illustrating the design of a conventional bright-field reflected light microscope is shown.

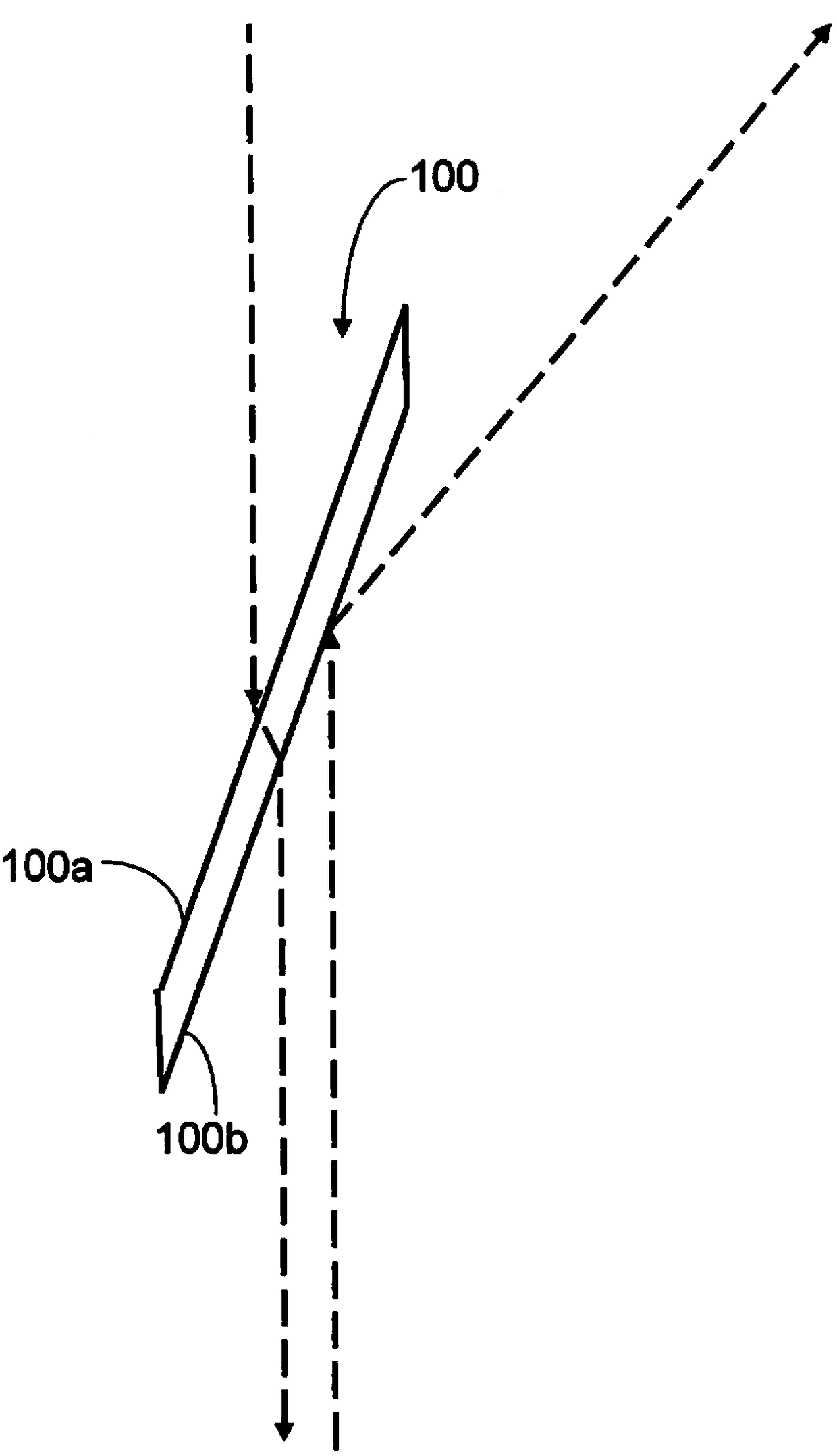

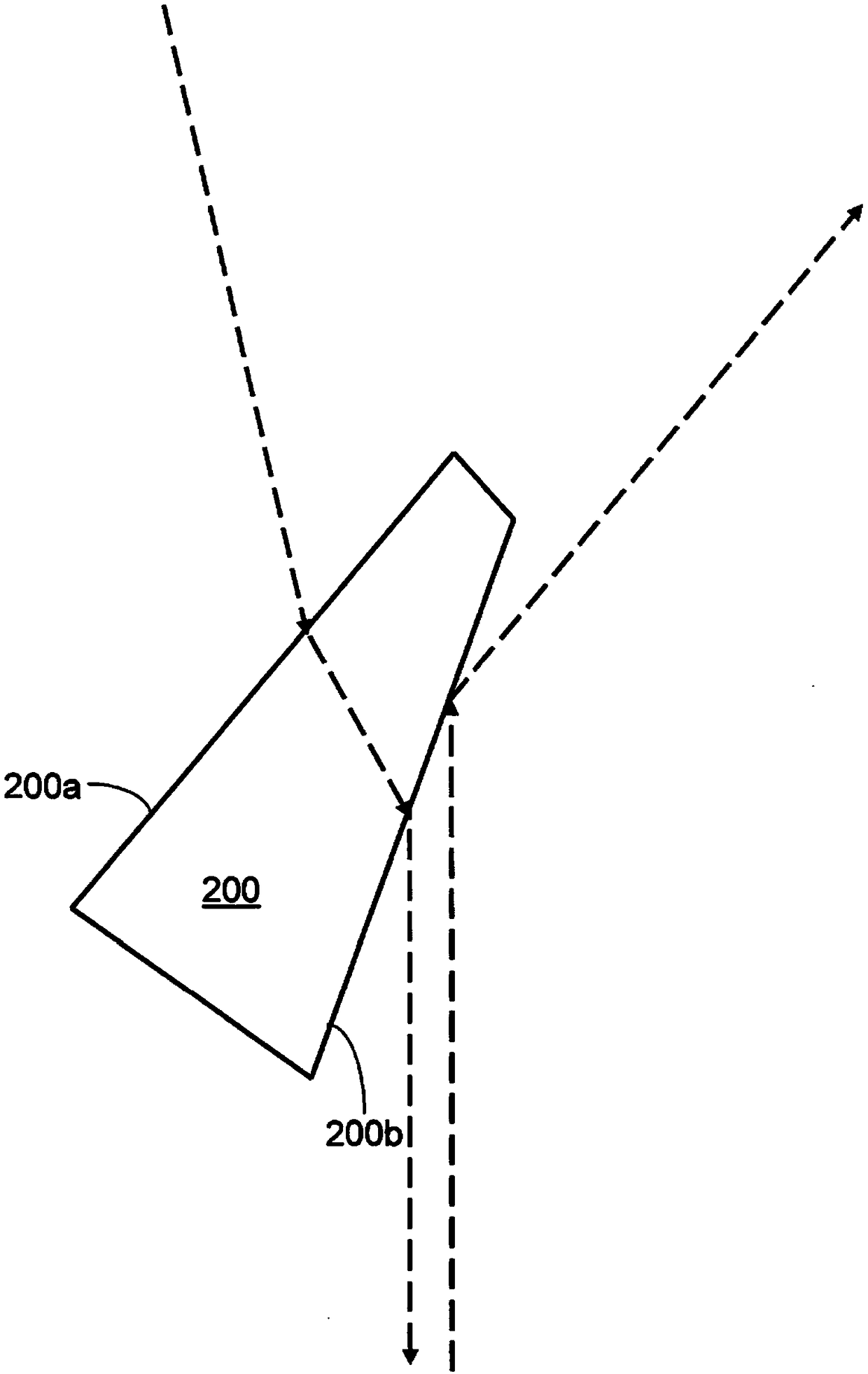

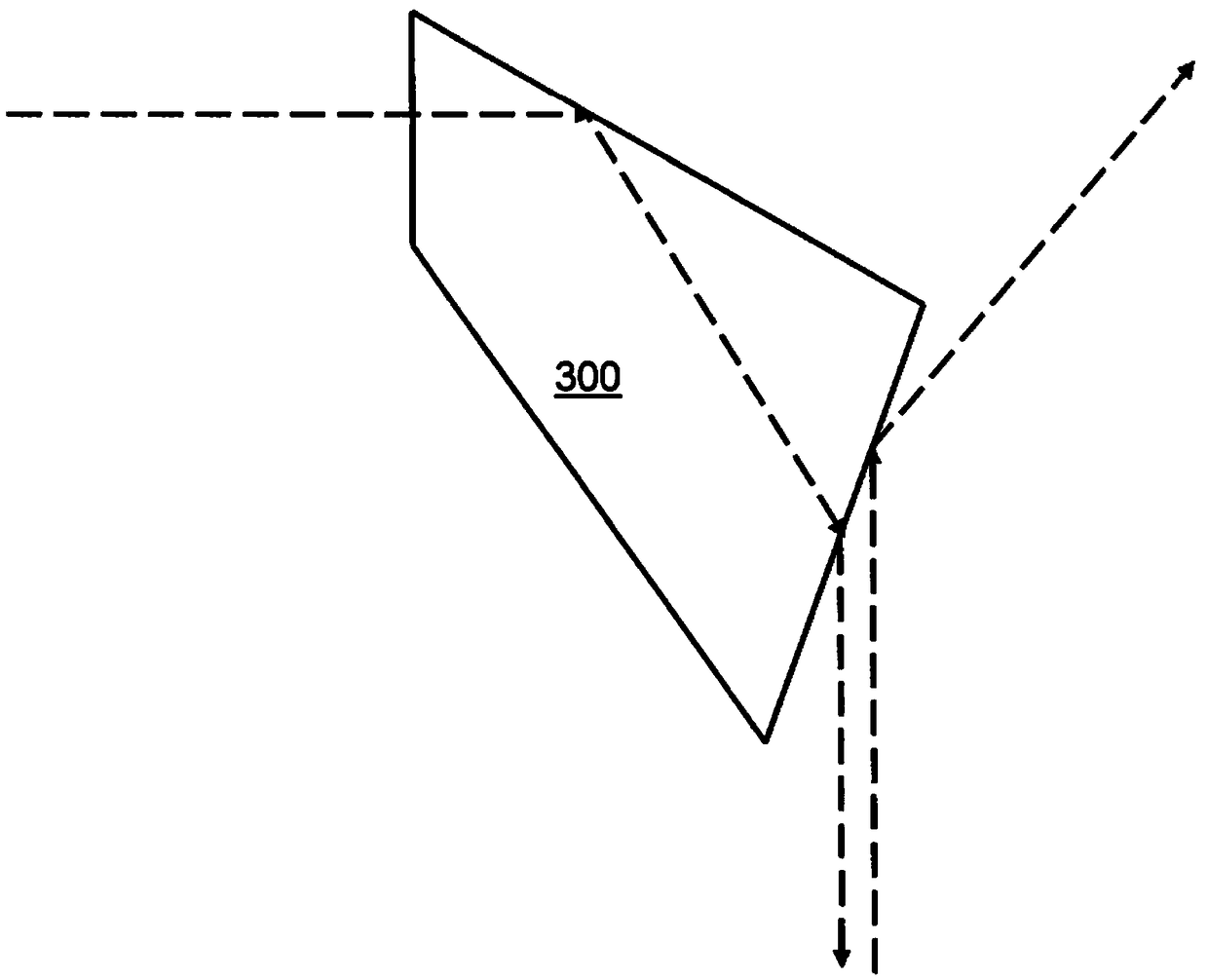

[0036] exist Figure 12 In the design of the bright-field reflected light microscope schematically shown in , the illumination light is incident on the beam splitter 10, is reflected in a proportion at its first interface 10a and is transmitted in a proportion. The reflected scale passes through the microscope objective 15 to the object plane OP, is reflected at the sample to be investigated located in the object plane OP, is again scaled and then transmitted through the beam splitter 10, via its second interface 10b to the detector 20.

[0037] The invention is not limited to implementation in such microscopes. For example, the invention or a beam splitter with a design according to the invention can also be implemented in other applications, for example for inspecting reticles or Mask inspection system for masks.

[0038] The following will ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com