Low-acrylamide deep-fried fish fillet wrapped with paste and processing method thereof

A processing method and acrylamide technology are applied in the field of food processing to achieve the effect of reducing the content of acrylamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Making fish nuggets: Remove the head, tail, bones, fins, scales, skin and viscera of fresh and live fish, clean them, and store them in a freezer at -20°C. Take out the ready-to-use fish and thaw at 4°C for 12 hours, then cut into fish pieces of the same size and thickness, each weighing 20-30g.

[0040] (2) Deodorization and salting: Soak the fish pieces in 2% tea liquid for 2 hours to remove the fishy smell, and the mass ratio of fish pieces to tea liquid is 1:1g / g. Put the fish pieces into 3% salt water and marinate for 30 minutes.

[0041] (3) Preparation of wrapping paste: 60g of medium-gluten wheat flour, 40g of cornstarch, 1g of baking powder, 2g of salt, 0.3g of xanthan gum, 0.9g of soybean fiber, 98g of water, mix, and stir with a mixer at 1000r / min for 10min to form a uniform paste shape.

[0042] (4) Coating and drying: Put the fish pieces into the wet batter, take out the batter and put it into the bread crumbs to ensure that the bread crumbs are evenl...

Embodiment 2

[0048] Steps (1), (2) are the same as in Example 1.

[0049] (3) Prepare the batter for wrapping: 60g of medium-gluten wheat flour, 40g of corn starch, 1g of baking powder, 2g of salt, 0.4g of xanthan gum, 0.8g of soybean fiber, and 98g of water, mix them, and stir them with a mixer at 1000r / min for 10min to form a uniform paste shape.

[0050] Steps (4), (5) are the same as in Example 1.

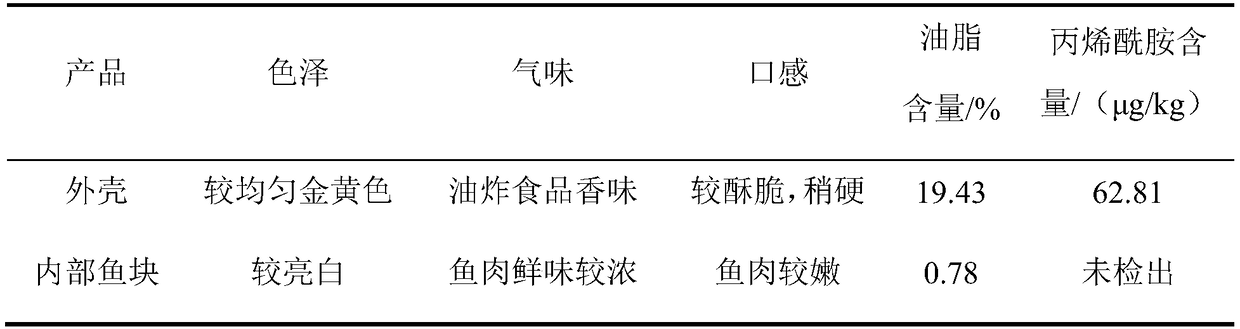

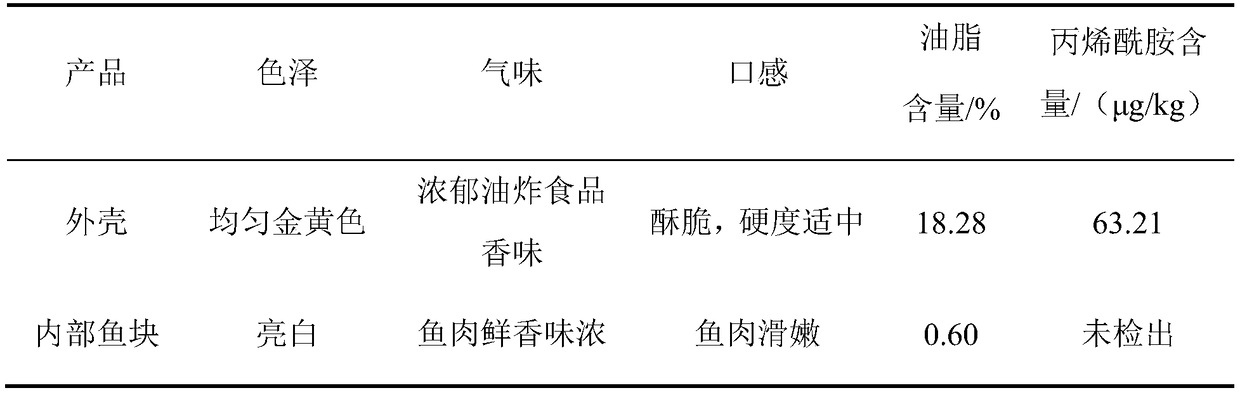

[0051] The product sensory and measured indicators are shown in Table 2.

[0052] Table 2 Product Evaluation Indicators

[0053]

Embodiment 3

[0055] Steps (1), (2) are the same as in Example 1.

[0056] (3) Prepare the batter for wrapping: 60g of medium-gluten wheat flour, 40g of corn starch, 1g of baking powder, 2g of salt, 0.6g of xanthan gum, 0.6g of soybean fiber, and 98g of water, mix them, and stir them with a mixer at 1000r / min for 10min to form a uniform paste shape.

[0057] Steps (4), (5) are the same as in Example 1.

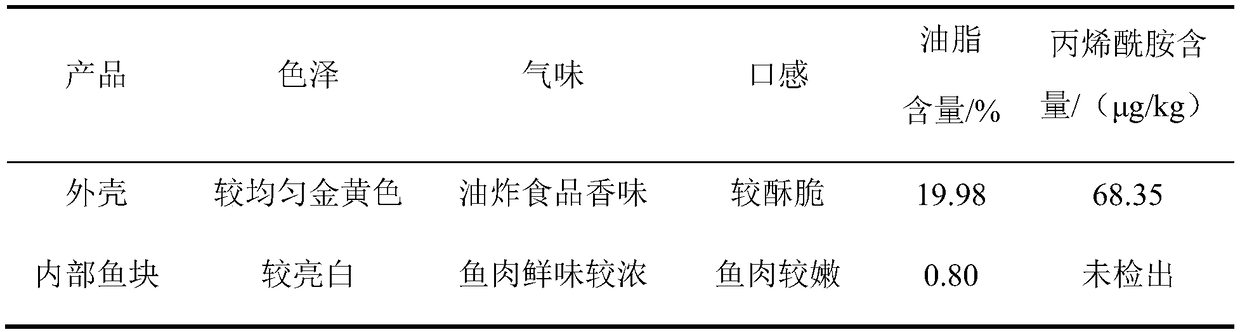

[0058] The sensory and measured indicators of the product are shown in Table 3.

[0059] Table 3 Product Evaluation Indicators

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com