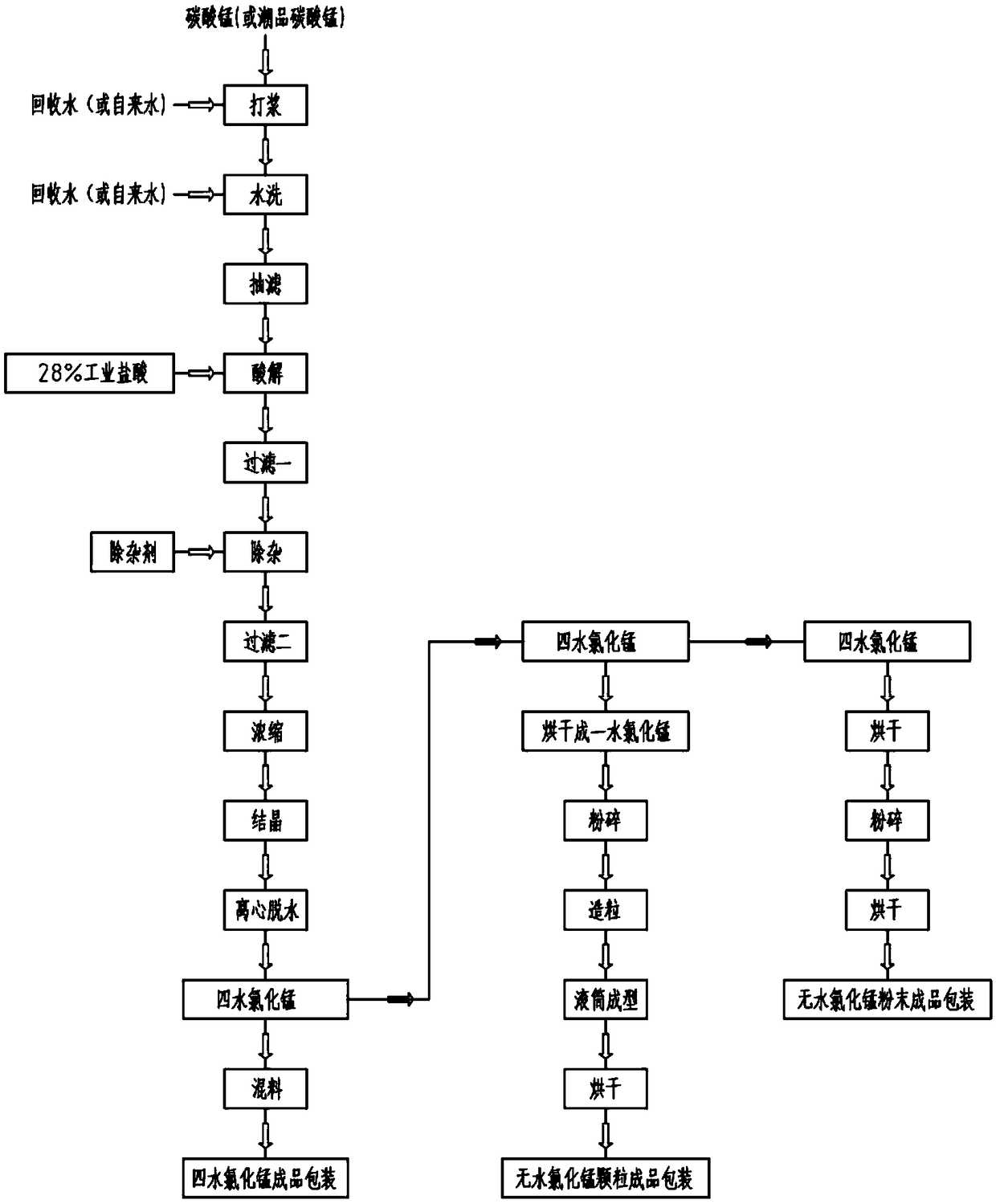

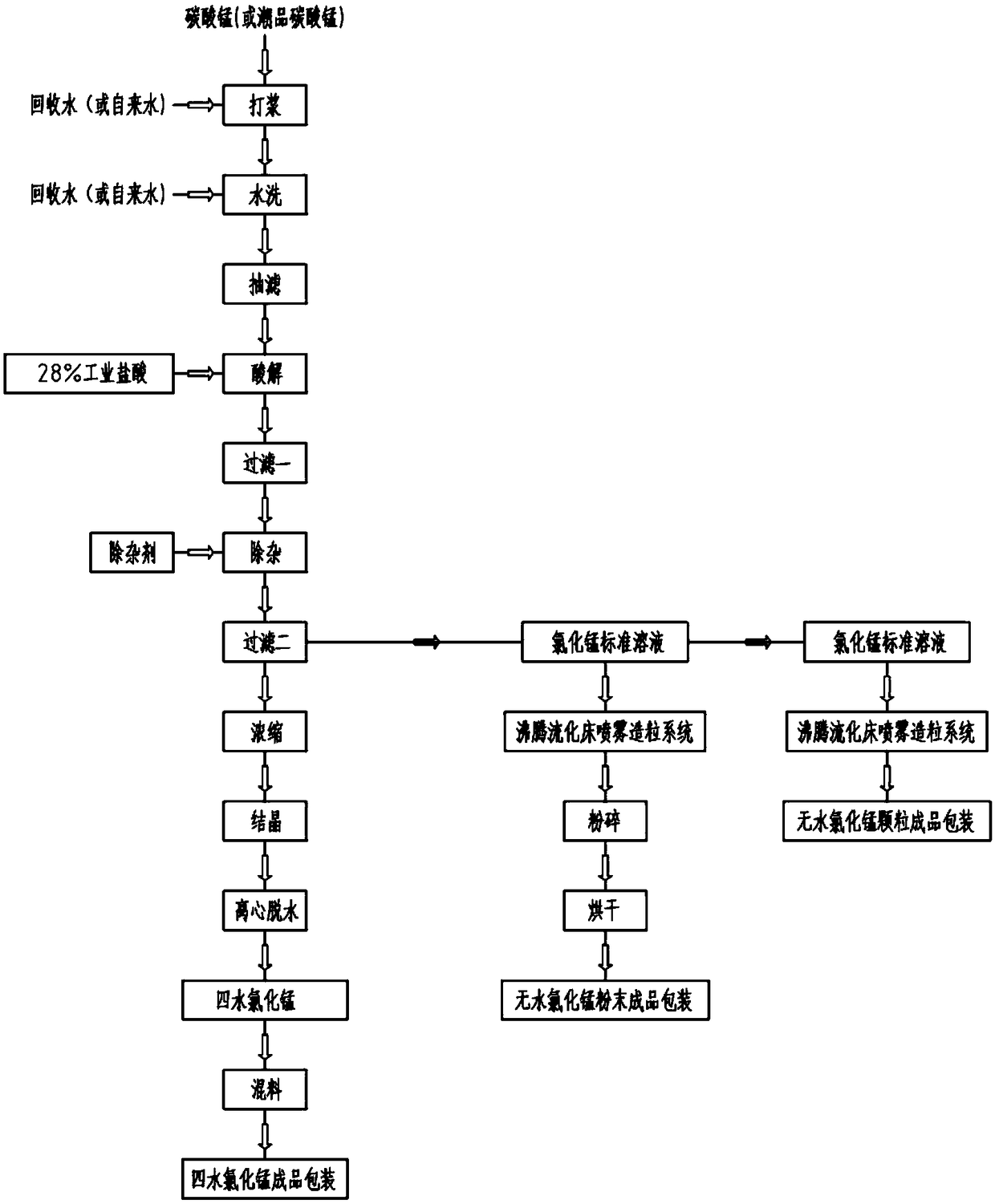

Production technology of manganese chloride

A production process, manganese chloride technology, applied in the direction of manganese halide, etc., can solve the problems of many impurities, single product, and inability to obtain manganese chloride in various forms, so as to achieve the effect of improving purity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030] A manganese chloride production process, comprising the following steps,

[0031] S1, beating, put manganese carbonate or tide manganese carbonate into a beating machine for beating treatment, before beating, inject recycled water or tap water into the beating machine, after beating fully, obtain beating liquid A;

[0032] S2, water washing, stir the beating liquid A evenly and pump it into the washing tank, then add an appropriate amount of water, stir for 1 hour, stop stirring, settle for 3 hours, pump the upper layer of water, filter it through the plate frame, and then go to the sewage neutralization pool , the material suspended in the water recovered by the plate frame is reused, and a small amount of water and materials left in the washing tank are stirred evenly, and then pumped into the suction filter tank to obtain the washing liquid B;

[0033] S3, suction filtration, using a water ring vacuum pump to drain the water in the suction filtration tank, the mangan...

Embodiment approach 2

[0045] A manganese chloride production process, comprising the following steps,

[0046] S1, beating, put manganese carbonate or tide manganese carbonate into a beating machine for beating treatment, before beating, inject recycled water or tap water into the beating machine, after beating fully, obtain beating liquid A;

[0047] S2, water washing, stir the beating liquid A evenly and pump it into the washing tank, then add an appropriate amount of water, stir for 1 hour, stop stirring, settle for 3 hours, pump the upper layer of water, filter it through the plate frame, and then go to the sewage neutralization pool , the material suspended in the water recovered by the plate frame is reused, and a small amount of water and materials left in the washing tank are stirred evenly, and then pumped into the suction filter tank to obtain the washing liquid B;

[0048] S3, suction filtration, using a water ring vacuum pump to drain the water in the suction filtration tank, the mangan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com