Control method of high-pressure common rail system pressure-limiting valve

A technology of a high-pressure common rail system and a control method, which is applied in the control field of a pressure-limiting valve, can solve the problems of poor vehicle power and economy, failure to realize active opening control, analysis of the opening times of the pressure-limiting valve, and cumulative opening time analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be described in detail below in conjunction with specific illustrations and embodiments.

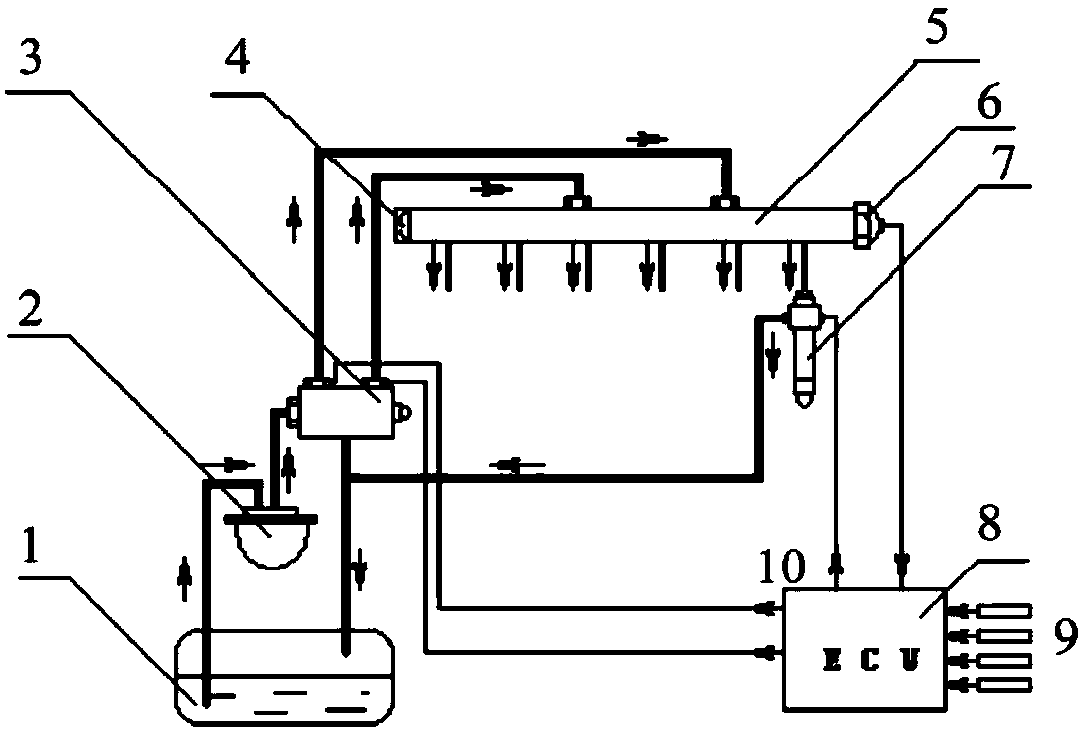

[0076] figure 1 It is a schematic diagram of the high pressure common rail fuel system structure. The low-pressure fuel is sucked from the fuel tank 1 to the fuel filter 2, and the high-pressure fuel pump 3 compresses a part of the low-pressure fuel into high-pressure fuel and sends it to the common rail pipe 5, which acts as a pressure accumulator, and the excess part is discharged from the high-pressure fuel pump 3 The overflow valve on the upper part flows back to the fuel tank 1 together with the oil return of the fuel injector 7; the high-pressure fuel flows from the common rail pipe 5 to the fuel injector 7 of each cylinder through the high-pressure fuel pipe; the fuel injector 7 The output pulse start point and pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com