Gas barrier film and wavelength conversion film

A technology of wavelength conversion and wavelength conversion layer, which is applied in the direction of gaseous chemical plating, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problems of luminous intensity decrease and quantum dot deterioration, and achieve high durability, The effect of good light diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0426]

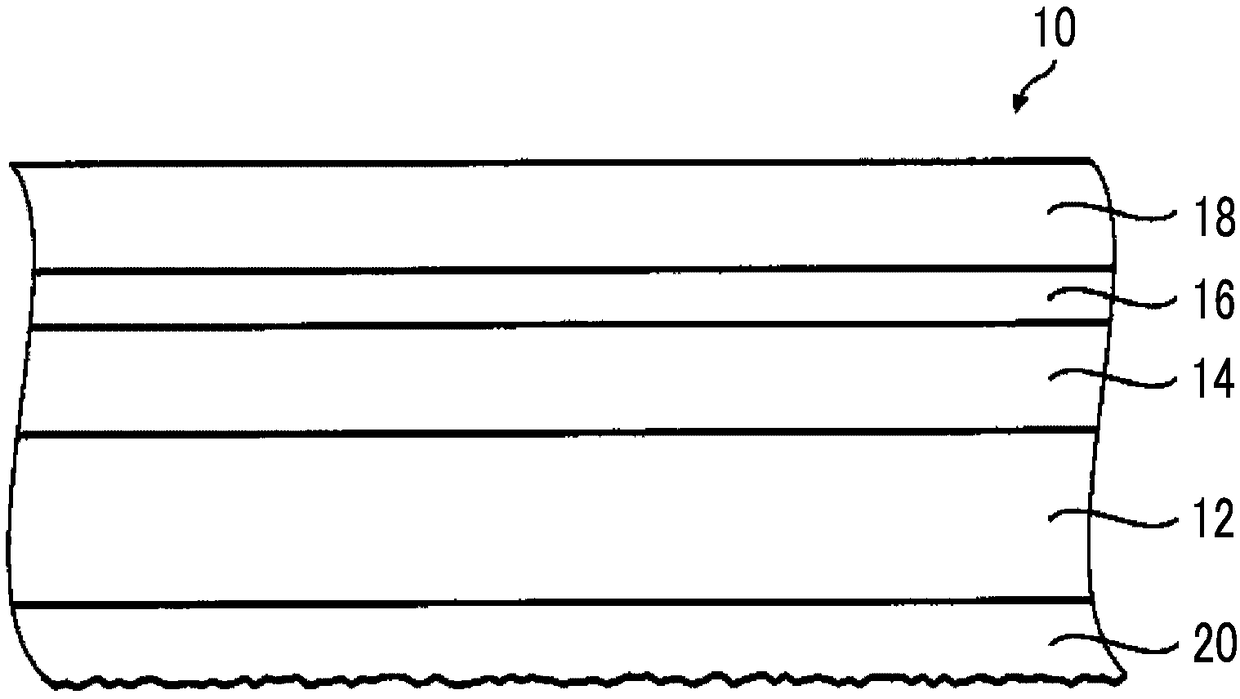

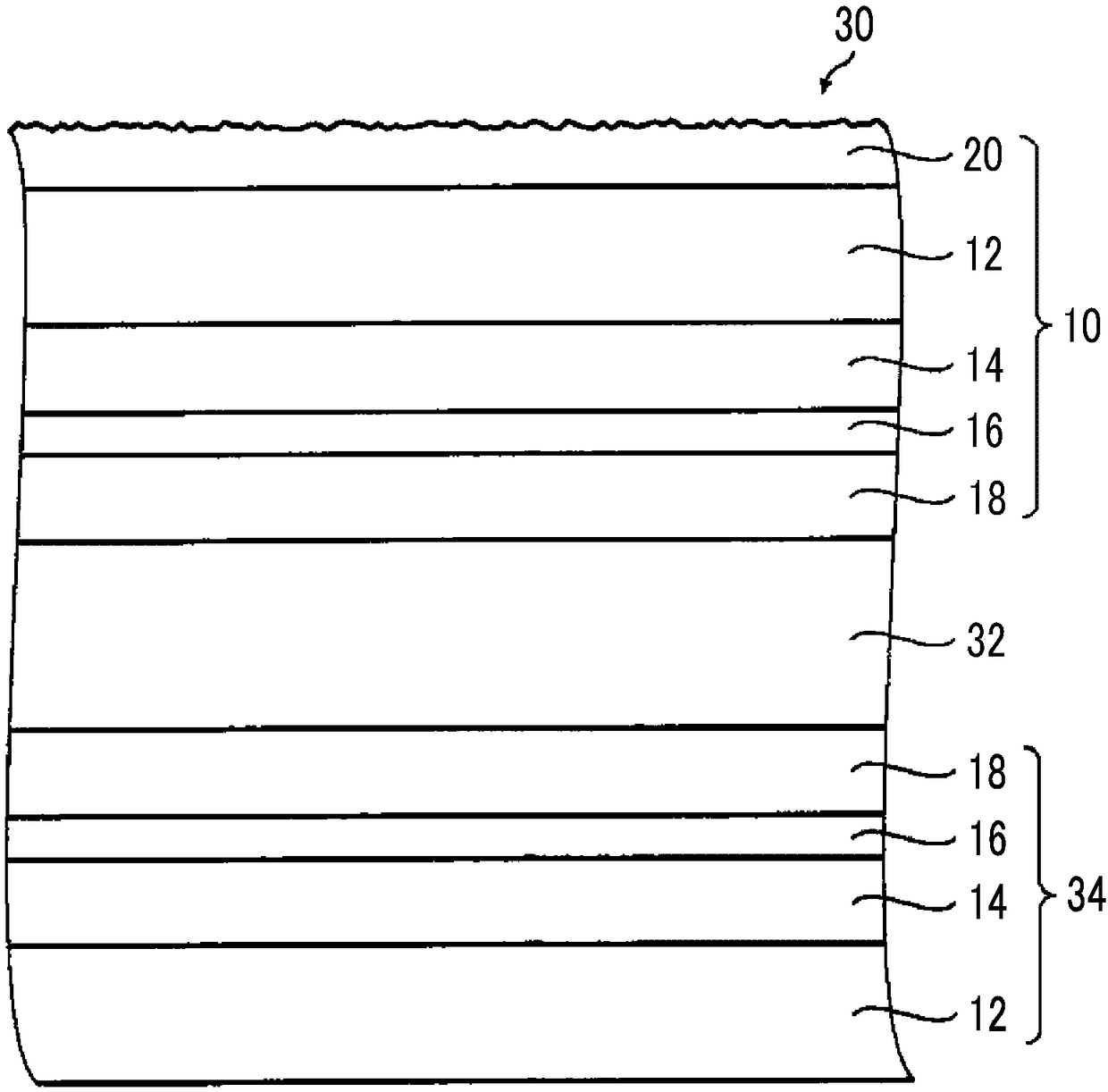

[0427] Make on one side of support body 12, have base organic layer 14, inorganic layer 16 and adhesive layer 18, have light diffusion layer 20 on the opposite side such as figure 1 The barrier film 10 is shown.

[0428] The support body 12 used a PET film (COSMOSHINE A4300 manufactured by Toyobo Co., Ltd.) having a width of 1000 mm, a thickness of 50 μm, and a length of 100 m.

[0429] >

[0430] TMPTA (manufactured by Daicel-Cytec Company, Ltd.) and a photopolymerization initiator (manufactured by Lamberti S.p.A, ESACURE KTO46) were prepared and weighed so that the mass ratio became 95:5. These were dissolved in methyl ethyl ketone (MEK) so that the solid content concentration became 15 mass %, and the coating composition for forming the base organic layer 14 was prepared.

[0431] In the coating section of a general RtoR film-forming device, which has a coating section using a die coater, a drying area using warm air, and a curing area using ultraviolet radiati...

Embodiment 1-2

[0458] In the polymerizable composition for forming the light diffusion layer 20, the first component, the second component and the third component are added to the binder component, and a urethane acrylate oligomer (manufactured by Sartomer Company, Inc, CN9178NS , n=1.469), the mass ratio of the solid content is formulated to be 60:15:15:10 in terms of the first component: the second component: the third component: urethane acrylate oligomer. Except for this, the barrier film 10 was produced in the same manner as in Example 1.

[0459] The refractive index n1 of the adhesive was calculated in the same manner as in Example 1 and was 1.471, so the difference n1-n2 of the refractive indices was 0.051.

[0460] In addition, when the Tg of the adhesive was measured in the same manner as in Example 1-1, it was 59°C.

Embodiment 1-3

[0462] In the polymerizable composition for forming the light diffusion layer 20, the second component of the binder component was changed from ACRIT8KX012C manufactured by Taisei Fine Chemical Co., Ltd. to ACRIT8KX056 manufactured by Taisei Fine Chemical Co., Ltd. (n = 1.48, Tg=111 degreeC), and the barrier film 10 was produced in the same manner as Example 1 except this.

[0463] The refractive index n1 of the adhesive was calculated in the same manner as in Example 1 and was 1.472, so the difference n1-n2 in the refractive index was 0.052.

[0464] In addition, when the Tg of the binder was measured in the same manner as in Example 1-1, it was 67°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| double bond equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com