Air bladder press for raspberry wine

A press, raspberry wine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unguaranteed juice quality, high labor intensity, time-consuming and labor-intensive, etc., to achieve microbial risk control, reduce labor intensity, and convenient and efficient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific structural composition and design principle of the airbag press for raspberry wine of the present invention are provided below in conjunction with the accompanying drawings, which are used to further describe the present invention in detail.

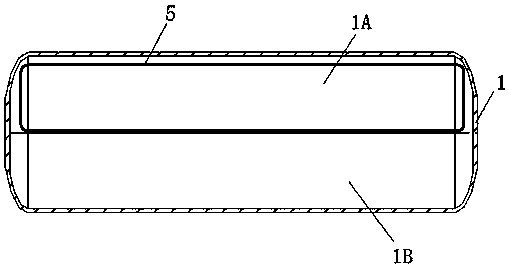

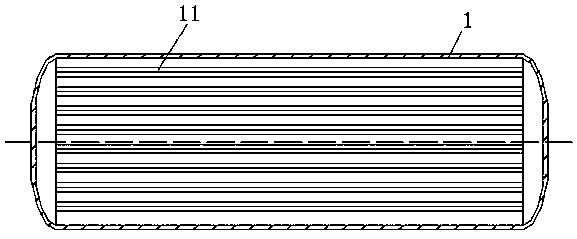

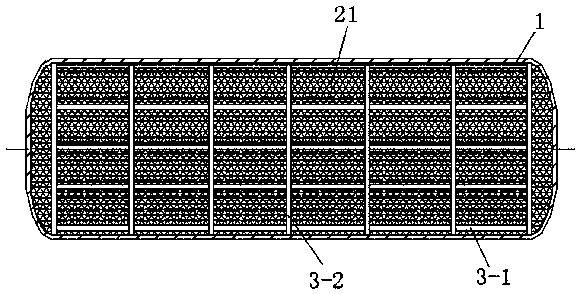

[0037]The airbag press for raspberry wine includes a tank body 1 with a horizontal cylinder structure as a whole. According to different function settings, the tank body 1 is divided into two half-tanks, one of which is a half-tank It is set as the air bag action area 1A with the air bag 5 installed, and the other half-tank is set as the press filter area 1B with the press filter assembly installed; the press filter assembly is integrated on the tank wall of the half tank body, including The inner wall of the tank body 1 is uniformly distributed in the axial direction and protrudes toward the center of the tank body with several ribs 11, which form a channel for collecting and diverting filtrate between the ribs 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com