Early-strength-type polycarboxylic acid high-performance water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent is applied in the field of concrete admixtures, which can solve the problems of early strength effect and material environmental adaptability that cannot meet the market application requirements of early strength and super early strength concrete, and achieves the effect of simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An early-strength polycarboxylate high-performance water reducer, the synthetic raw material contains a large molecular weight isopentenyl polyoxyethylene ether macromonomer and a dendritic macromolecular comonomer with methacrylic acid-terminated butylenediamine as the core .

[0055] The synthetic raw material also contains unsaturated sodium sulfonate comonomer, unsaturated carboxylic acid comonomer, initiator, reducing agent, chain transfer agent, liquid caustic soda and water.

[0056] The molecular weight of the isopentenyl polyoxyethylene ether macromonomer with large molecular weight is 4000-6000.

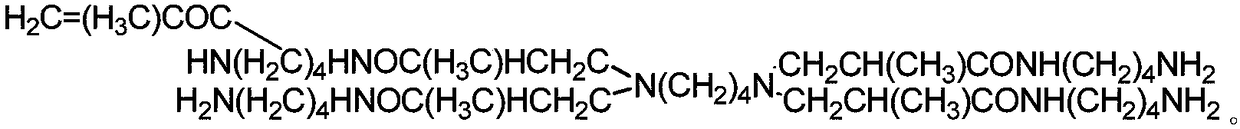

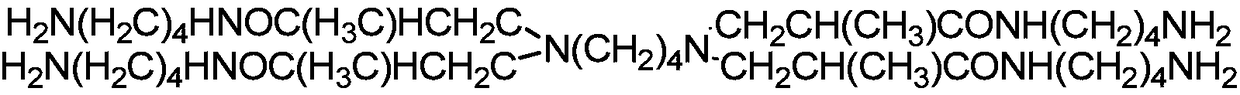

[0057] The butanediamine of methacrylic acid end-capping is the chemical formula of the dendritic macromolecule comonomer of nucleus as follows:

[0058]

[0059] In parts by mass, the ratio of synthetic raw materials is,

[0060] Large molecular weight isopentenyl polyoxyethylene ether macromonomer: 350-400 parts;

[0061] Dendritic macromolecular comonomer with...

Embodiment 2

[0095] A preparation method of an early-strength polycarboxylate high-performance water reducer, comprising the following steps,

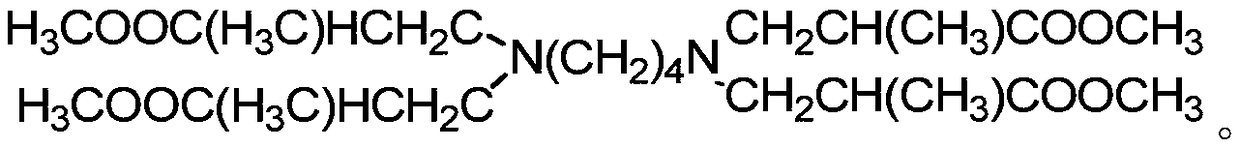

[0096] (1) Preparation of methacrylic acid-terminated butanediamine as a core dendritic macromolecular comonomer: add 25 parts of methanol A and 6.5 parts of butanediamine A to the reactor, and stir at 50°C until butanediamine A was completely dissolved, and 36 parts of methyl methacrylate was added dropwise for 0.5 h, and the reaction was carried out at 50°C for 10 h, and the intermediate I was obtained by distillation under reduced pressure.

[0097] Add a solution prepared by adding 32 parts of butanediamine B and 30 parts of methanol B to intermediate I, react at 90°C for 10 hours, and distill under reduced pressure to obtain intermediate II;

[0098] Add 6 parts of methacrylic acid and 0.2 parts of inhibitor hydroquinone to intermediate II, N 2 Under the atmosphere, stirred at 70°C for 3h, and distilled under reduced pressure to obtain a dend...

Embodiment 3

[0101] A preparation method of an early-strength polycarboxylate high-performance water reducer, comprising the following steps,

[0102] (1) Preparation of methacrylic acid-terminated butanediamine as a core dendritic macromolecular comonomer: add 20 parts of methanol A and 8 parts of butanediamine A to the reactor, stir until butanediamine is stirred at 55°C A was completely dissolved, and 35 parts of methyl methacrylate was added dropwise for 0.5 h, and the reaction was carried out at 55°C for 12 h, and intermediate I was obtained by distillation under reduced pressure.

[0103] Add a solution prepared by adding 35 parts of butanediamine B and 25 parts of methanol B to intermediate I, react at 100°C for 12 hours, and distill under reduced pressure to obtain intermediate II;

[0104] Add 7 parts of methacrylic acid and 0.3 parts of inhibitor hydroquinone to intermediate II, N 2 Stirring at 80° C. for 4 h under the atmosphere, and distilling under reduced pressure to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com