Method for increasing surface hardness of hydrophilic anti-fogging coating, hydrophilic self-cleaning coating and hydrophobic self-cleaning coating

An anti-fog coating and surface hardness technology, which is used in anti-fouling/underwater coatings, paints containing biocides, optics, etc., can solve the problems that anti-fog coatings cannot continue to be promoted and increase the surface hardness of anti-fog spectacle lenses. , to achieve the effect of promoting the expansion of market capacity and industrial scale, the construction process is simple and easy, and the wear resistance and wiping resistance are excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

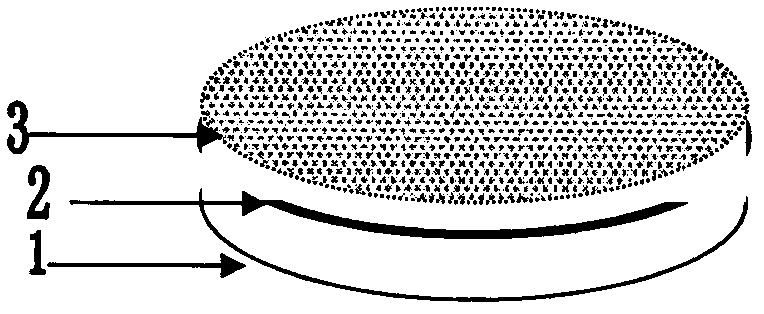

[0053] Embodiment 1: as figure 1 As shown, the matching anti-fog coating 2 is coated on the surface 1 of the substrate resin ophthalmic lens, and a layer of silicon dioxide microstructure coating 3 is vacuum-plated after curing (it can also be selected from titanium dioxide, zirconium dioxide, tantalum dioxide, oxide Indium tin, magnesium fluoride and other commonly used targets for optical glasses), can complete the manufacturing process of high hardness anti-fog glasses.

[0054] Transparent substrates such as security lenses, aviation glass, automotive glass, architectural glass, bathroom mirrors, and window products can be manufactured by this method.

Embodiment 2

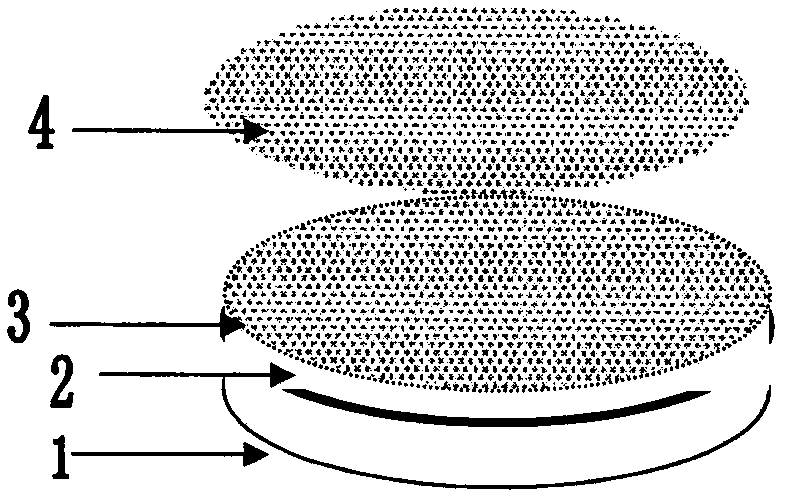

[0055] Embodiment 2: as figure 2 As shown, the matching anti-fog coating 2 is coated on the substrate resin ophthalmic lens 1, and after curing, a two or more layers of silicon dioxide and metal oxides such as titanium, tantalum, zirconium, and indium tin are coated with two or more composite coatings. Microstructure coatings 3 and 4 can complete the manufacturing process of anti-fog spectacle lenses with high hardness and anti-reflection and anti-reflection functions. Of course, the selected target material should be recalculated according to the design requirements of the optical lens and the different refractive index of the target material, and the thickness of the film layer should be recalculated—it will neither damage the anti-fog effect nor affect the function of anti-reflection and anti-reflection. Other anti-fog products that require anti-reflection and anti-reflection functions can be manufactured according to this method.

Embodiment 3

[0056] Embodiment 3: as figure 1 As shown, the matching hydrophilic (hydrophobic) coating 2 is coated on the stainless steel surface 1 of the base material, and after curing, a layer of stainless steel microstructure coating 3 is vacuum-plated, and the high-hardness hydrophilic and self-cleaning stainless steel product can be completed. Manufacturing process.

[0057] The target material and base material can be selected differently, for example, the stainless steel base material chooses a silica target material, etc., whichever meets the product design and use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com