Efficient cattle carcass surface sterilization method

A beef carcass, high-efficiency technology, used in slaughtering accessories, slaughtering, and chemical preservation of meat/fish, etc., can solve problems such as poor sanitation, high initial bacterial count, and beef production accounting for less than 10%, to ensure safety. , the effect of prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

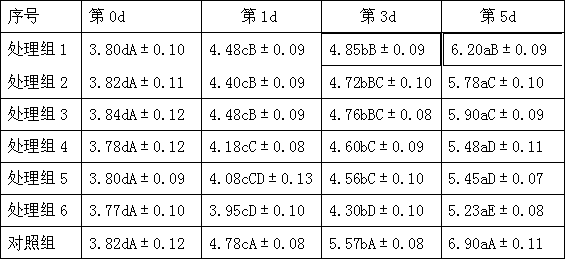

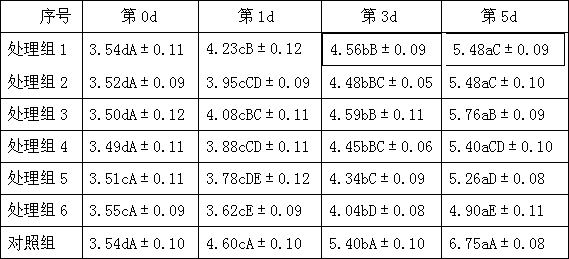

Examples

preparation example Construction

[0034] 2.2.1. Activation of strains and preparation of bacterial suspension

[0035] Zhang Tiehua et al. studied and analyzed the bacteria on the surface of fresh beef and found that G(-) small bacilli and G(+) cocci are the main bacterial strains that cause the spoilage. Therefore, Escherichia coli and Staphylococcus aureus were used in this test. As the introduction of bacteria to study the effect of reducing bacteria. Take out the slant strains frozen in the refrigerator, and in a sterile environment, use a sterilized inoculation loop to pick an appropriate amount of strains and streak them on the nutrient agar medium, and culture them at a constant temperature of 37°C for 24 hours. Pick a single obvious colony in LB nutrient broth, put it in a constant temperature culture shaker at 37°C, and culture it on a 220r / min shaker for 12h, so that the number of bacteria reaches 1×107cfu / mL, and obtain the original bacterial liquid, and put it in the refrigerator for later use.

...

Embodiment 1

[0053] Treatment group 1 was selected as the treatment object, and the bacteria reduction method was high-pressure water gun washing. The specific treatment method was to wash with high-pressure water with a total pressure of about 1.87 MPa for 5 minutes, and the water temperature was 25 °C.

Embodiment 2

[0055]Select treatment group 2 as the treatment object, and the bacteria reduction method is ozone water spraying. The specific treatment method is to insert the catheter of the ozone generator (400mg h-1) into pure water at 25°C, turn on the ozone generator for 30min, and prepare ozone water, let stand for 30min, and control the ozone concentration to 2mg·L-1. Each piece of meat was sprayed with 100mL of ozone water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com