Application of dry granulating technology in the preparation of milk slices

A technology of dry granulation and dry granulator, which is applied in the fields of application, dairy products, milk preparations, etc., can solve the problems of silicon dioxide use safety risks, no nutritional value, and no benefit to the human body, so as to overcome the hazards and risks, Good integrity and gloss, improved powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

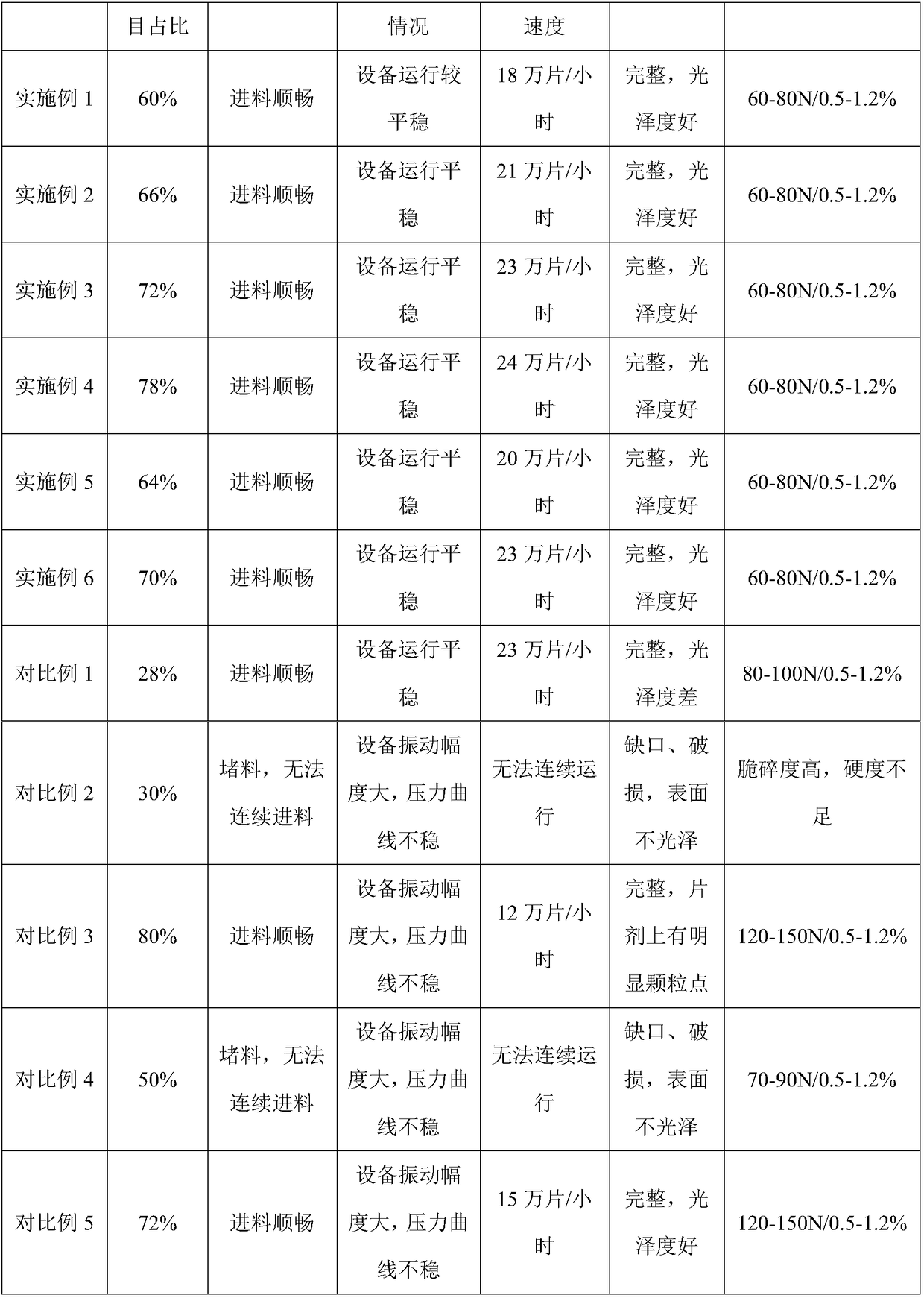

Embodiment 1

[0031] Preparation of milk flakes:

[0032] The milk tablet base powder (with whole milk powder as the main raw material, adding glucose syrup, edible vegetable oil, white sugar, food flavors, nutrients, etc., after batching, sterilization, vacuum concentration and spray drying, the milk solid content is not low. 70% of the modulated milk powder used to produce milk tablets.) The vacuum feeder sucks the material into the dry granulator (manufacturer: Shijiazhuang Keyuan Machinery Equipment Co., Ltd., dry granulator model: GZL150-40L, below The model of the dry granulator used in each embodiment and comparative example is all identical with this embodiment), dry granulator process parameter: vertical feeding speed is 16rpm; Horizontal feeding speed is 50rpm; Press roller pressure is 7MPa; Press roller The rotation speed is 8rpm; the sieve structure of the granulation system is an orifice selection plate; the sieve diameter of the granulation system is 12 mesh, the upper sieve d...

Embodiment 2

[0035] Preparation of milk flakes:

[0036] The whole milk powder is sucked into the dry granulator through the vacuum feeder, and the process parameters of the dry granulator are as follows: the vertical feeding speed is 18rpm; the horizontal feeding speed is 80rpm; the pressing roller pressure is 10MPa; the pressing roller rotating speed is 10rpm; The system screen structure selects the sieve plate; the sieve diameter of the granulation system is 14 mesh, the sieve mesh diameter of the upper layer of the vibrating screen of the screening system is 5 mesh, and the sieve mesh diameter of the lower layer is 60 mesh. The prepared granules were pressed into shape by a tablet press, and the parameters of the tablet press were set at a pressure of 8 kN.

[0037] After dry granulation, the water content of whole milk powder particles is below 8%, and the particle size distribution is 10-100 mesh particles account for 66% of the total weight of the particle powder, of which 10-20 mes...

Embodiment 3

[0039] Preparation of milk flakes:

[0040] The skimmed milk powder is sucked into the dry granulator through the vacuum feeder. The process parameters of the dry granulator are: the vertical feeding speed is 23rpm; the horizontal feeding speed is 100rpm; the pressing roller pressure is 12MPa; the pressing roller rotating speed is 12rpm; The sieve structure is selected from the sieve plate; the sieve diameter of the granulation system is 14 mesh, the sieve mesh diameter of the upper layer of the vibrating screen of the screening system is 8 mesh, and the sieve mesh diameter of the lower layer is 100 mesh. The prepared granules were pressed into shape by a tablet press, and the parameters of the tablet press were set at a pressure of 8 kN.

[0041] After dry granulation, the water content of skim milk powder particles is below 8%, and the particle size distribution is 10-100 mesh particles account for 72% of the total weight of the particle powder, of which 10-20 mesh accounts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com