DHA algae oil microcapsule powder and preparation method thereof

A technology of microcapsules and algae oil, which is applied in the direction of food ingredients as antioxidants, the function of food ingredients, and the formation of food, etc., which can solve the problem of not being able to balance the physiological and health needs of the human body, and the long-term storage of oils and fats, which are easily oxidized by the environment and become rancid. problem, to achieve the effect of increasing shelf life, enhancing memory and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

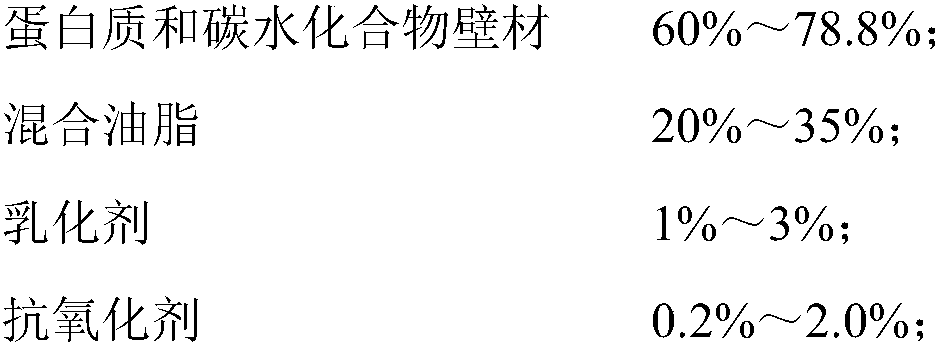

[0054] Embodiments 1-3 provide a DHA algae oil microcapsule powder and a preparation method thereof, and the contents of each component and weight percentage thereof are shown in Table 1.

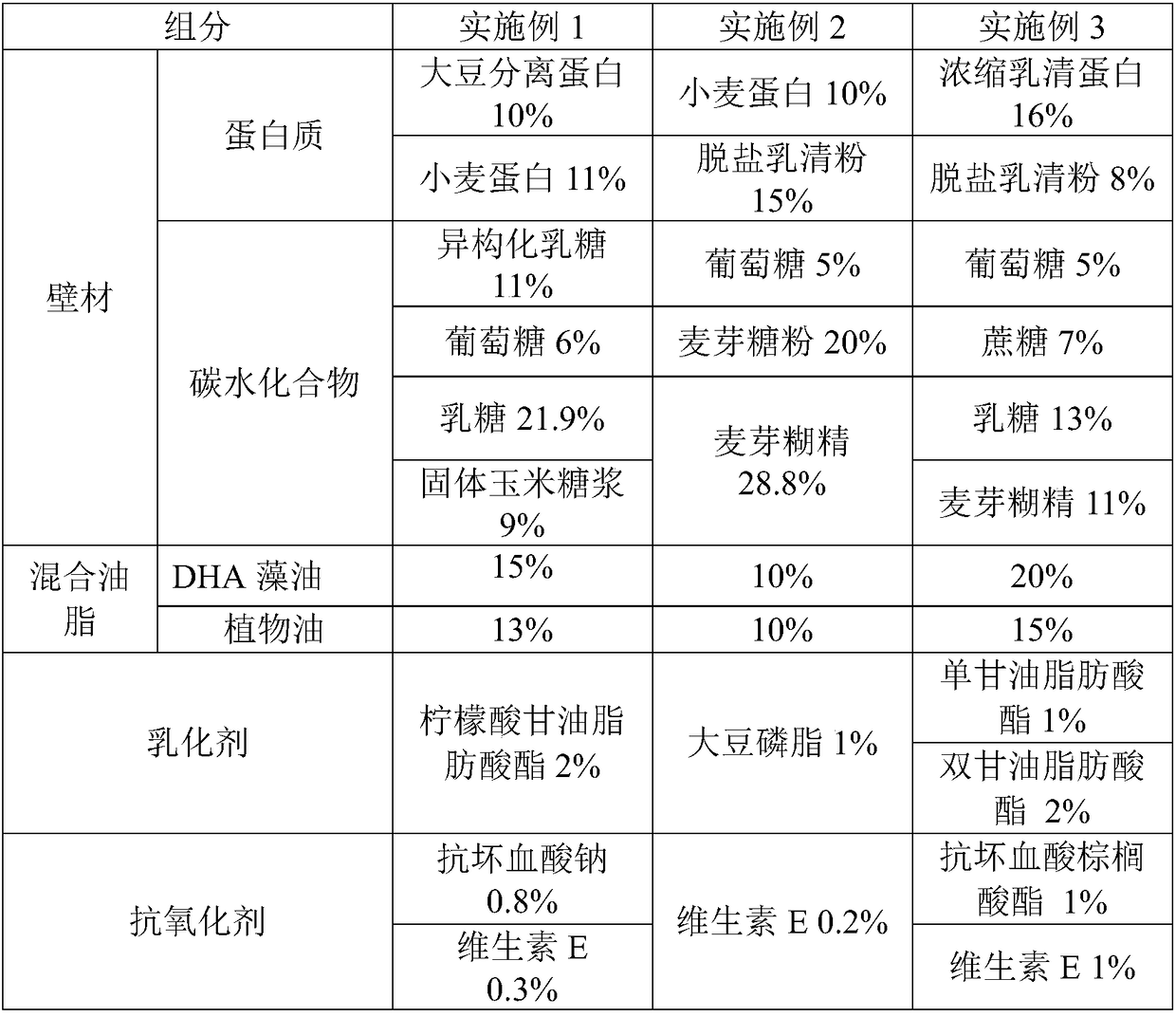

[0055] The DHA oils of Examples 1-3 are derived from DHA algae oil fermented by microorganisms, and are extracted without solvent. The specific results are shown in Table 3.

[0056] In the mixed oils used in Examples 1-3, in the DHA algae oil, the mass content of saturated fatty acids is 20%-40%, and the mass content of polyunsaturated fatty acids is 60%-80%; in vegetable oils, the mass content of saturated fatty acids 10%-20%, and the mass content of monounsaturated fatty acid is 60%-80%.

[0057] Wherein, the saturated fatty acid is palmitic acid and stearic acid; the monounsaturated fatty acid is oleic acid, and the oleic acid is derived from one or both of olive oil and camellia seed oil; the polyunsaturated fatty acid is DPA and DHA, and in the DHA algae oil, the weight content of D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com