Sucrose fine particles and preparation method, equipment and application thereof

A fine particle, sucrose technology, applied in lighting and heating equipment, powder suspension granulation, pharmaceutical formulations, etc., can solve the problems of unsmooth feeding, poor mixing, poor fluidity of powdered sugar, etc. Good solubility and good compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

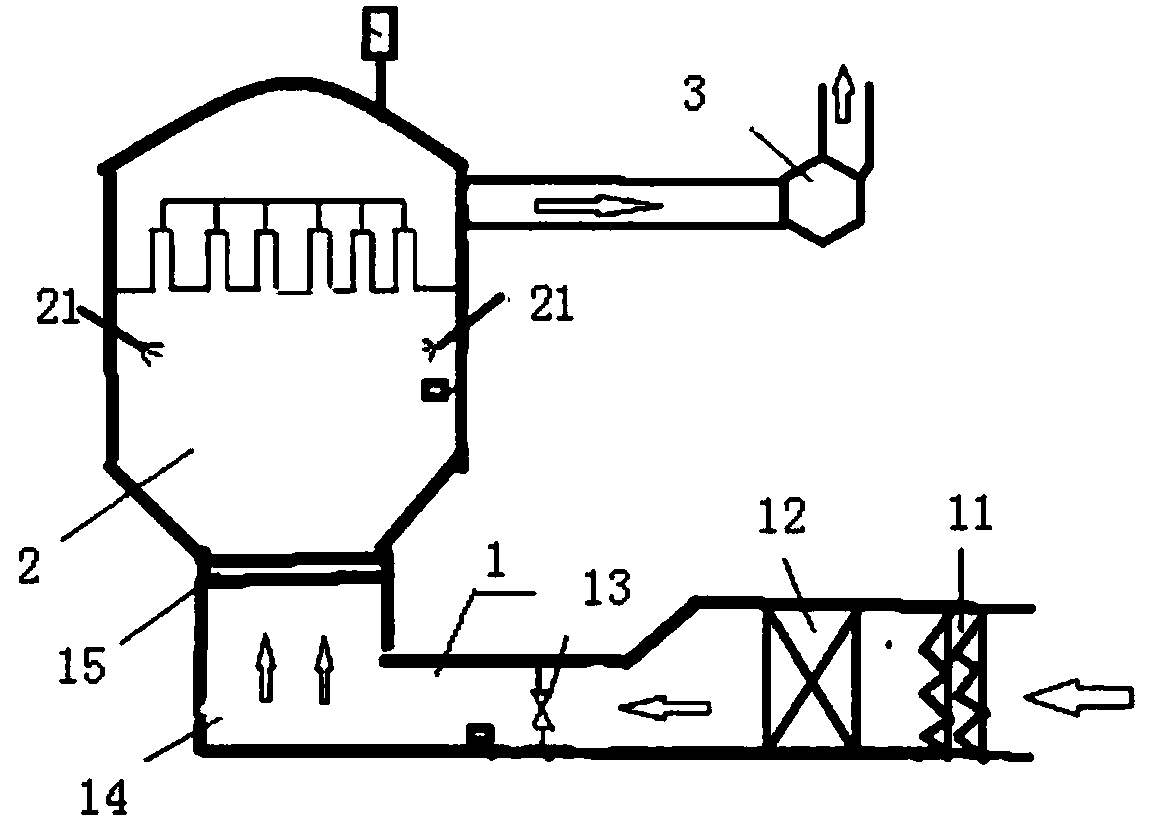

[0042] The preparation of embodiment 1 sucrose fine particle

[0043] Commercially available sucrose is pulverized to obtain powdered sugar with a particle size of 20-30 meshes. The obtained powdered sugar is blown up with hot air in the fluidized bed, and water is sprayed at the same time. The ratio of the volume of the fluidized bed to the weight of the material is 10.75L / KG, the pressure of the water jet pump is 3 kg, and the hot air volume is 8000 cubic meters per hour. The prepared sucrose fine particles have a particle size of 60 meshes, an apparent density of 0.53 g / ml, and an angle of repose of 32°.

Embodiment 2

[0044] The preparation of embodiment 2 sucrose fine particles

[0045] Pulverize sucrose to obtain powdered sugar with a particle size of 20-30 meshes, blow up the obtained powdered sugar with hot air in the fluidized bed, and spray water at the same time, the ratio of the volume of the fluidized bed to the weight of the material is 10.75L / KG , the pressure of the water jet pump is 5 kg, and the hot air volume is 8000 cubic meters per hour. The prepared sucrose fine particles have a particle size of 70 meshes, an apparent density of 0.48 g / ml, and an angle of repose of 32°.

Embodiment 3

[0046] The preparation of embodiment 3 sucrose fine particles

[0047] Pulverize sucrose to obtain powdered sugar with a particle size of 20-30 meshes, blow up the obtained powdered sugar with hot air in the fluidized bed, and spray water at the same time, the ratio of the volume of the fluidized bed to the weight of the material is 10.75L / KG , the pressure of the water jet pump is 8 kg, and the hot air volume is 5000 cubic meters per hour. The prepared sucrose fine particles have a particle size of 80 meshes, an apparent density of 0.43 g / ml, and an angle of repose of 32°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com