Integrated laser cleaning photoelectric system

A laser cleaning and optoelectronic system technology, applied in the field of laser cleaning, can solve the problems that the laser cleaning terminal equipment cannot realize online monitoring, and cannot be used for precision cleaning, etc., to achieve high-precision and high-efficiency laser cleaning, and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

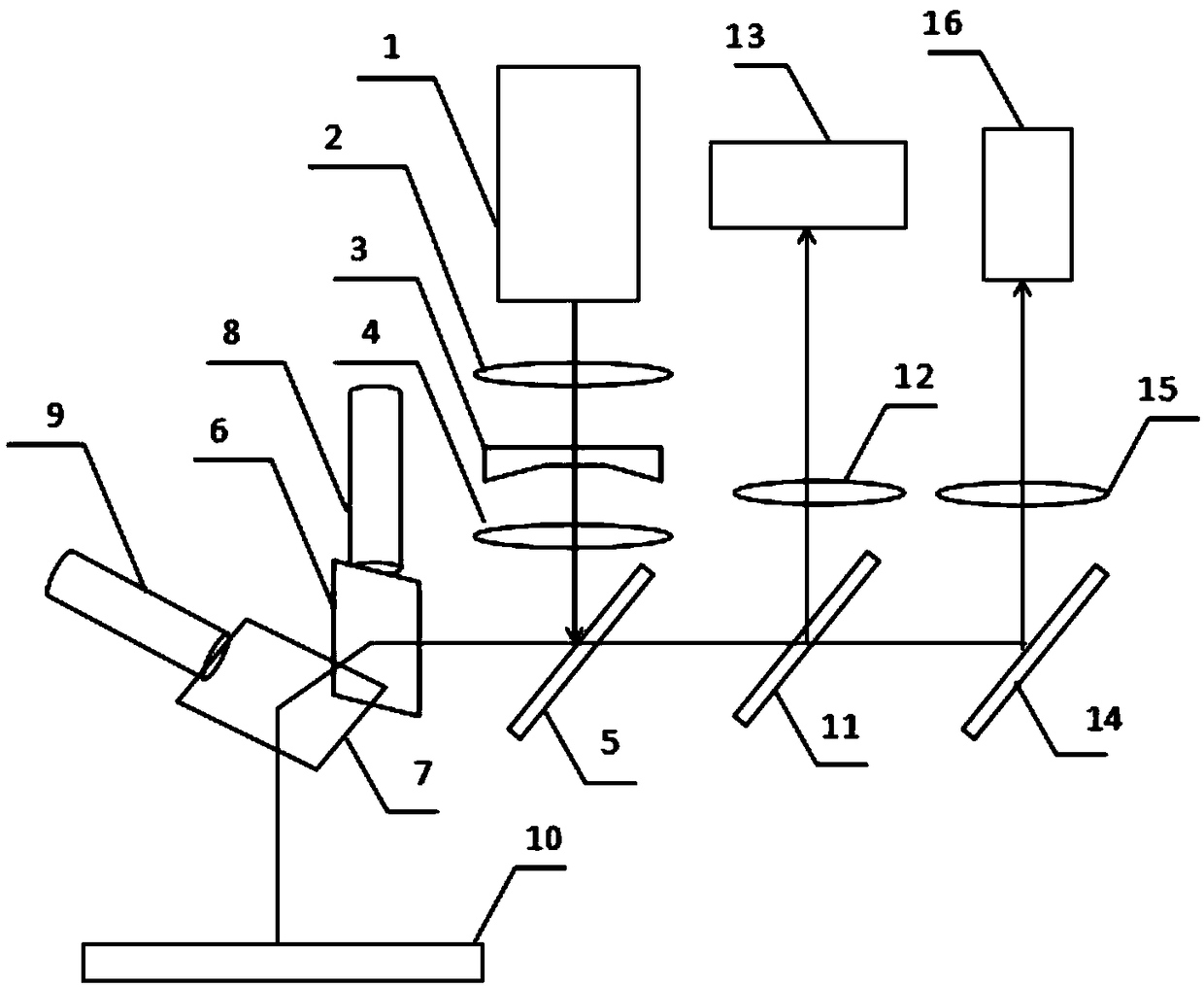

[0030] Such as figure 1 As shown, the collimating beam expanding optical assembly is located above the first optical mirror body 5, and the laser 1 is located above the collimating beam expanding optical assembly. The online monitoring component is located above the second optical mirror body 11 , and the spectrum analysis component is located above the third optical mirror body 14 . Specifically, the laser 1, the collimating lens 2, the concave lens 3, the convex lens 4 and the first optical mirror body 5 are on the same straight line; Above, high-speed camera 13, imaging lens 12 and second optical mirror body 11 are on the same straight line; The collection lens 15 and the third optical mirror body 14 are on the same straight line.

[0031] Among them, the laser 1 can be a solid-state or fiber laser, and can be a pulsed or continuous output laser, outputting a fundamental frequency 1064nm laser beam or a 532nm laser beam, and the direction of the laser beam emitted by the ...

Embodiment 2

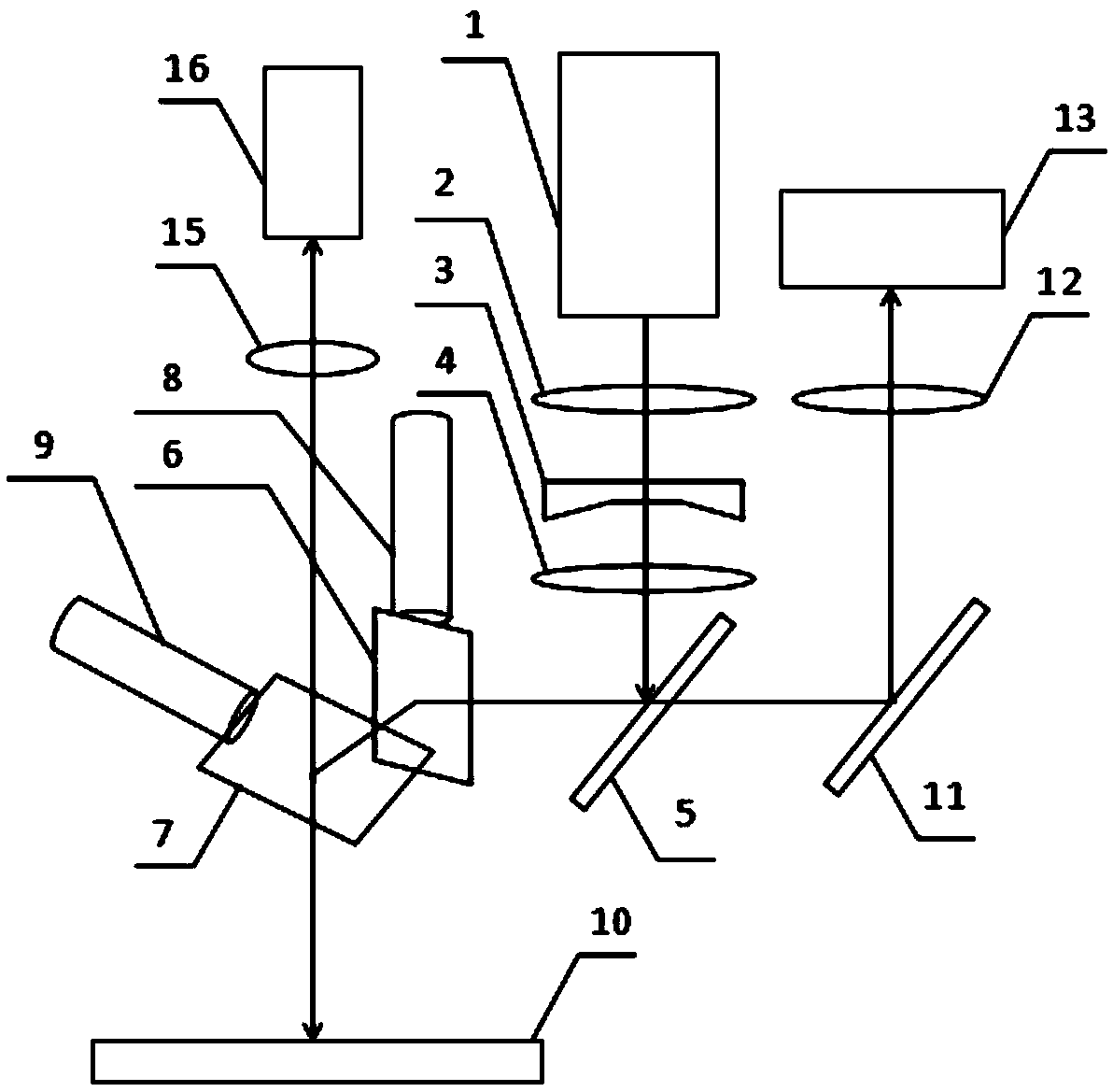

[0041] The difference with embodiment 1 is: as figure 2 As shown, the spectral analysis component is placed directly above the X-axis scanning galvanometer 7 , that is, the spectrum collection lens 15 is located directly above the X-axis scanning galvanometer 7 , and the spectrometer 16 is located directly above the spectrum collection lens 15 . At this time, the X-axis scanning galvanometer 7 is not only coated with an ultraviolet-enhanced aluminum film on the reflective surface, which can have a high reflectivity for the spectral signal in the 200nm-1100nm band, and the X-axis scanning galvanometer 7 is a half-transparent half-reflective mirror , has transflective properties in the 400nm-800nm band, so as to ensure that a part of the 400nm-800nm light wave signal can be transmitted, the X-axis scanning galvanometer 7 is incident on the surface of the spectrum collection lens 15, and then is focused by the spectrum collection lens 15 to the spectrometer 16 . At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com