A welding process method for mechanical seal components

A technology of mechanical sealing and process method, which is applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of small mechanical bonding force, poor thermal and electrical conductivity, and low effective bonding rate, and achieve strong mechanical bonding force and thickness Uniform and effective bonding effect with high rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A welding process method for a mechanical seal assembly, comprising the following steps:

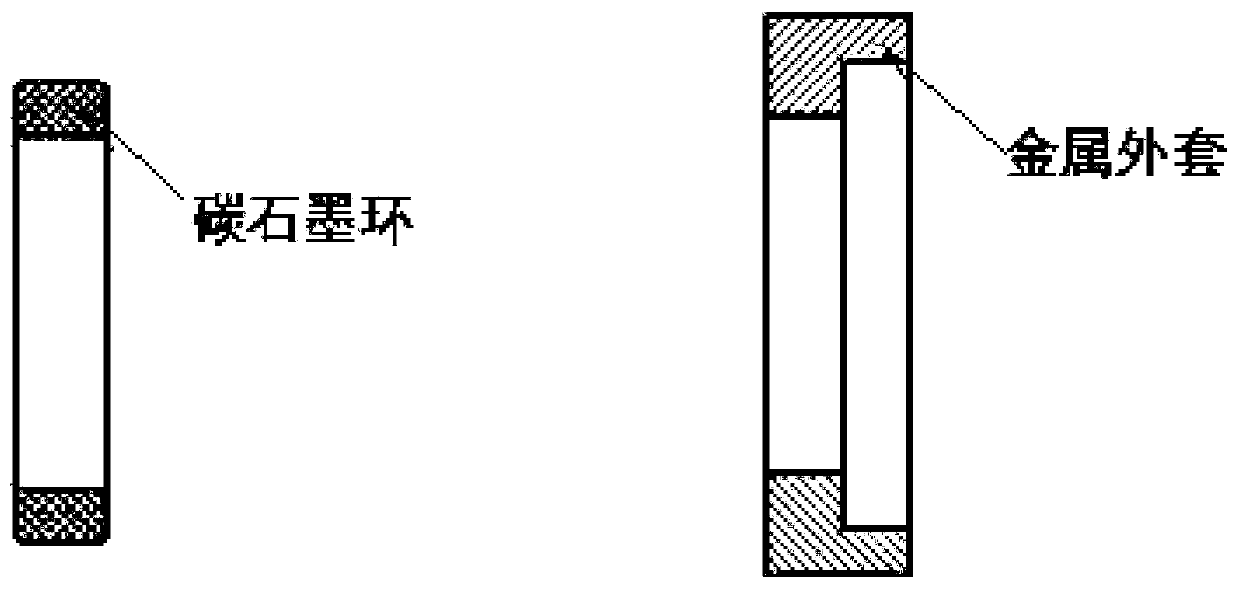

[0031] S1. Processing and forming carbon rings. The outer circle of the carbon ring is processed in place at one time, and processed to the target size. The inner circle and total length of the carbon ring leave a margin of 3-5mm for subsequent finishing. The carbon ring One end chamfer of the outer circle is 0.5*45°. A circular metal base matched with the carbon ring is processed and formed, and an annular accommodation groove for accommodating the carbon ring is provided on the inner side of the metal base.

[0032] S2. Carbon ring pretreatment: first put the processed carbon ring into the cleaning solution and soak it, then ultrasonically clean it, and finally rinse it with water until there is no dust on the surface of the carbon ring; then dry the cleaned carbon ring Dry.

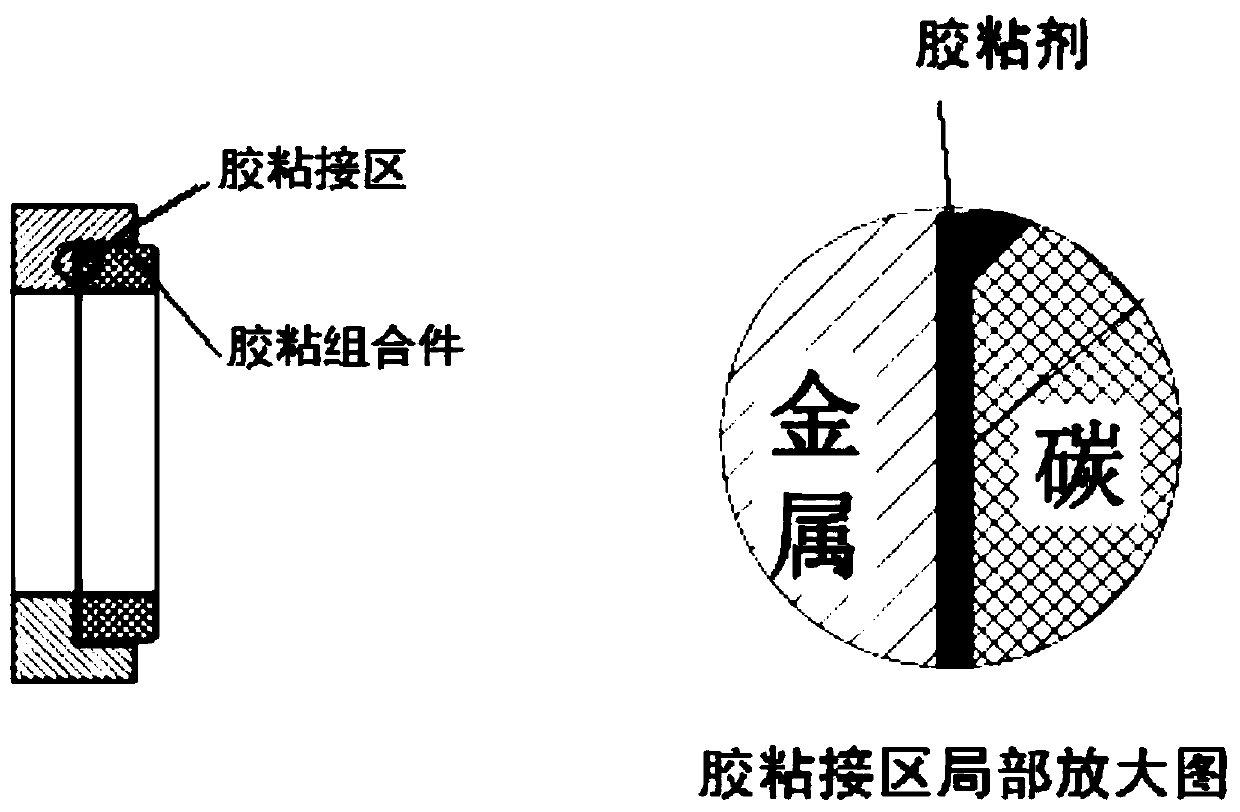

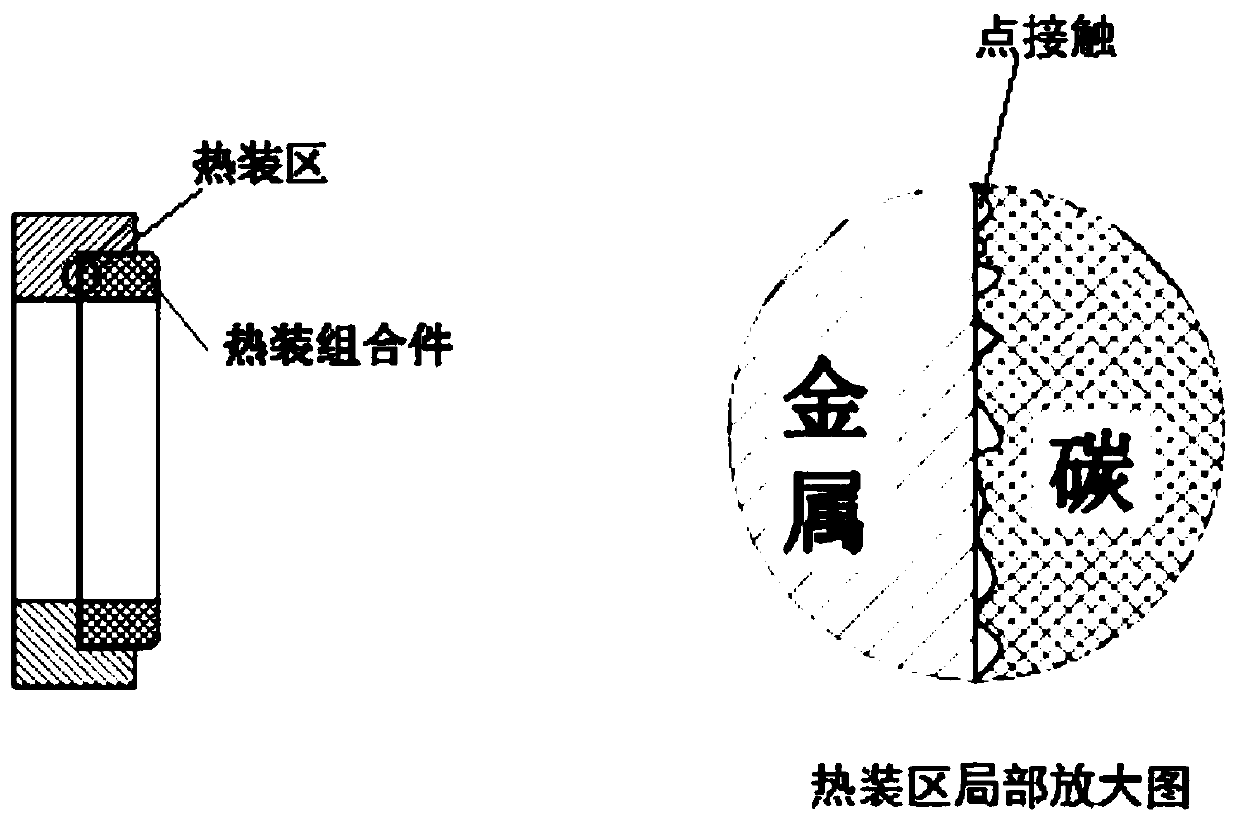

[0033] S3. Electroplating a metal nickel film or zinc film with a thickness of 0.1 mm on the outer su...

Embodiment 2

[0037] A welding process method for a mechanical seal assembly, comprising the following steps:

[0038] S1. Processing and forming carbon graphite ring, the outer circle of carbon graphite ring is processed in place at one time, processed to the target size, one end face chamfer of the outer circle is 0.5*45°, and the inner circle and total length of carbon graphite ring are left with 3 ~ 5mm Surplus for subsequent finishing. A circular metal base matched with the carbon-graphite ring is processed and formed, and an annular accommodation groove for accommodating the carbon-graphite ring is provided on the inner side of the metal base.

[0039] S2. Carbon-graphite ring pretreatment: first, soak the processed carbon-graphite ring in the cleaning solution, then ultrasonically clean it, and finally rinse with water until the surface of the carbon-graphite ring is free of dust; then put the cleaned carbon-graphite ring on the Dry at a temperature not exceeding 200°C.

[0040] S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com