A kind of insulating and heat-conducting fiber composite material for recyclable prestressed anchor cable and preparation method thereof

A fiber composite material and a technology for prestressed anchor cables, which are applied in the field of recyclable insulating and thermally conductive fiber composite materials for prestressed anchor cables and their preparation, can solve the problems of non-reusable prestressed anchor cables, obstacles to underground space development, and high construction costs. problems, to achieve the effects of good insulation, easy heating damage, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As used herein, the term "comprising", "comprising", "comprising", "having" is non-limiting, i.e., other steps and other components that do not affect the results can be added. The above terms cover terms "consisting of" and "consist of". " If there is no special instructions, materials, equipment, reagents are commercially available.

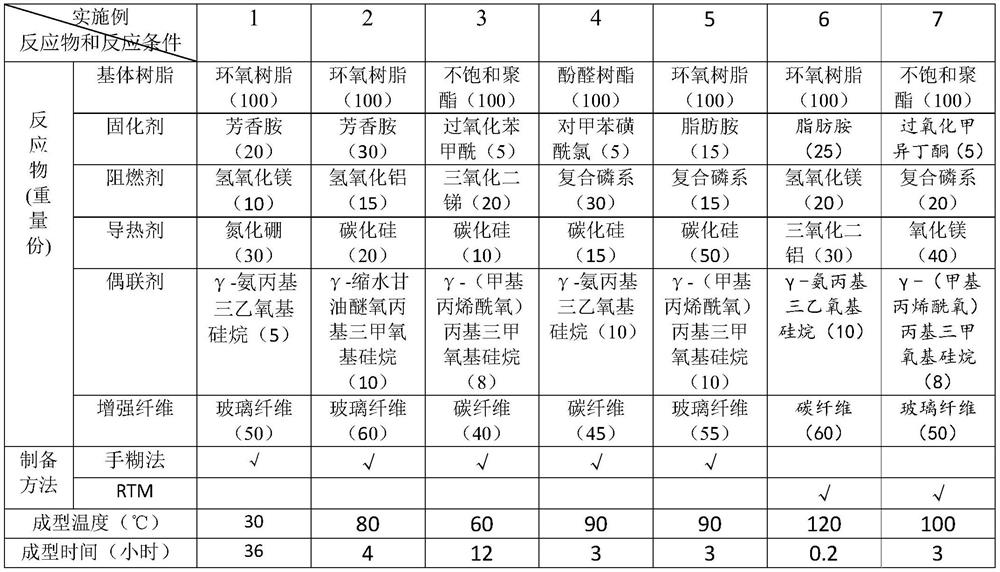

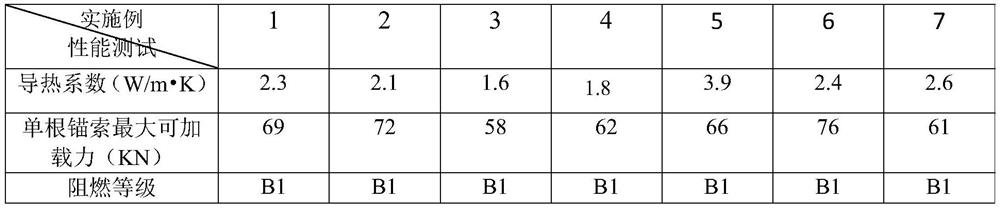

[0033] The present invention provides an insulating thermally conductive fiber composite material for recoverable prestressing indexes, and the amount of each component in the insulating thermally conductive fiber composite is as follows:

[0034] The matrix resin (can be an epoxy resin, an unsaturated polyester, a phenolic resin, and one or more of the furan resin;

[0035] Curing agent (can be a fatty amine, alicymlamine, aromatic amine, polyamide, oxyethyl ethyl ketone, peroxide, peroxide, oxide oxide, p-toluenesulfonyl chloride, isopenzene One or more of hydrogen peroxide, tert-butyl hydrogen peroxide, 2,4-dichlorobenzoyl oxide, and oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com