Euglena culture medium

A technology of culture medium and liquid culture medium, applied in the direction of unicellular algae, microorganism-based methods, microorganisms, etc., can solve the problems of high production cost and low fatty acid yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Example 1: Euglena slenderum ( Euglena gracilis ) by nitrosoguanidine (NTG) mutagenesis breeding and the acquisition of mutants

[0027] 1) Prepare PolyA medium according to the formula in Table 1

[0028] Table 1 PolyA medium for culturing in the present invention

[0029]

[0030] In the present invention, the solid PolyA medium is composed of 2 g of sodium acetate, 1 g of tryptone, 1 g of yeast extract, 10 g of agar powder, and water to 1 L.

[0031] 2) Preparation method of PBS solution

[0032] The PBS solutions of the present invention are all phosphate buffers of 0.2 mol / L and pH 7.0: from 0.2 mol / L Na 2 HPO 4 61mL with 0.2mol / L NaH 2 PO 4 39mL mixed.

[0033] 3) The preparation method of the 0.8mg / ml nitrosoguanidine (NTG) solution of the present invention

[0034] Consists of 1.6ml of 0.2M PBS (pH7.0) mixed with 4.0mg / ml NTG.

[0035] Prepare Heter liquid medium according to the formula in Table 2

[0036] Table 2 Heter liquid medium for culturin...

example 2

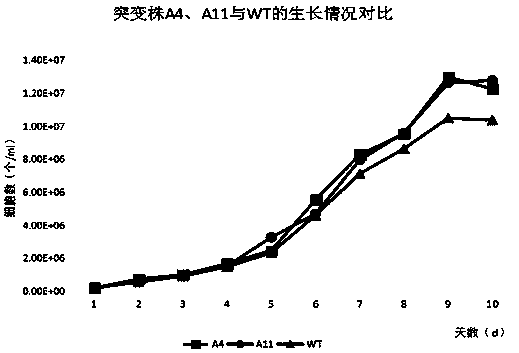

[0049] Example 2: Comparison of wild-type Euglena gracilis (WT) and mutant strains A4 and A11

[0050] 1. Comparison of growth rates

[0051] The obtained mutant strains A4 and A11 of Euglena slenderness were cultured in Heter liquid medium for 3-4 days, and inoculated into new Heter liquid medium at a volume ratio of 1:10, so that the number of cells after inoculation was 2.0×105 1 / ml, three parallel samples were taken for each group, 1ml of algal fluid was taken every day for hemocytometer counting, and the growth curve was drawn. In this step, the conditions are all light 65±5μmol / m 2 s 1 , 24h light, temperature 25±1℃. Comparison of the growth of wild-type Euglena slenderness (WT) and mutant strains A4 and A11 figure 2 shown.

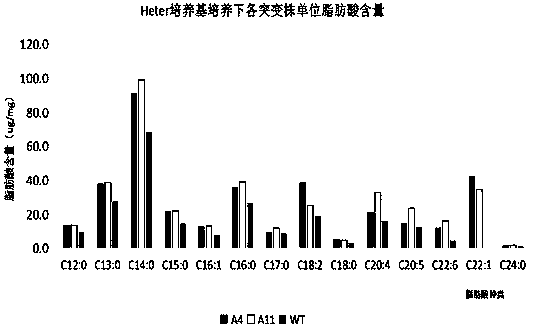

[0052] 2. Comparison of fatty acid content

[0053] 1) Extraction of fatty acids

[0054] The algal strain is cultured in a culture flask, and the growth plateau phase is reached after 9 days of culture. During this period, the accumulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com