A method for recovering rare earths by reusing mother liquor after ammonium bicarbonate is used to precipitate rare earths in the leaching solution of weathering crust elution type rare earth ore

A weathering crust leaching type, ammonium bicarbonate technology, applied in the field of hydrometallurgy, can solve the problems of not allowing the use of strong acids and alkalis, unable to supply sulfuric acid, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

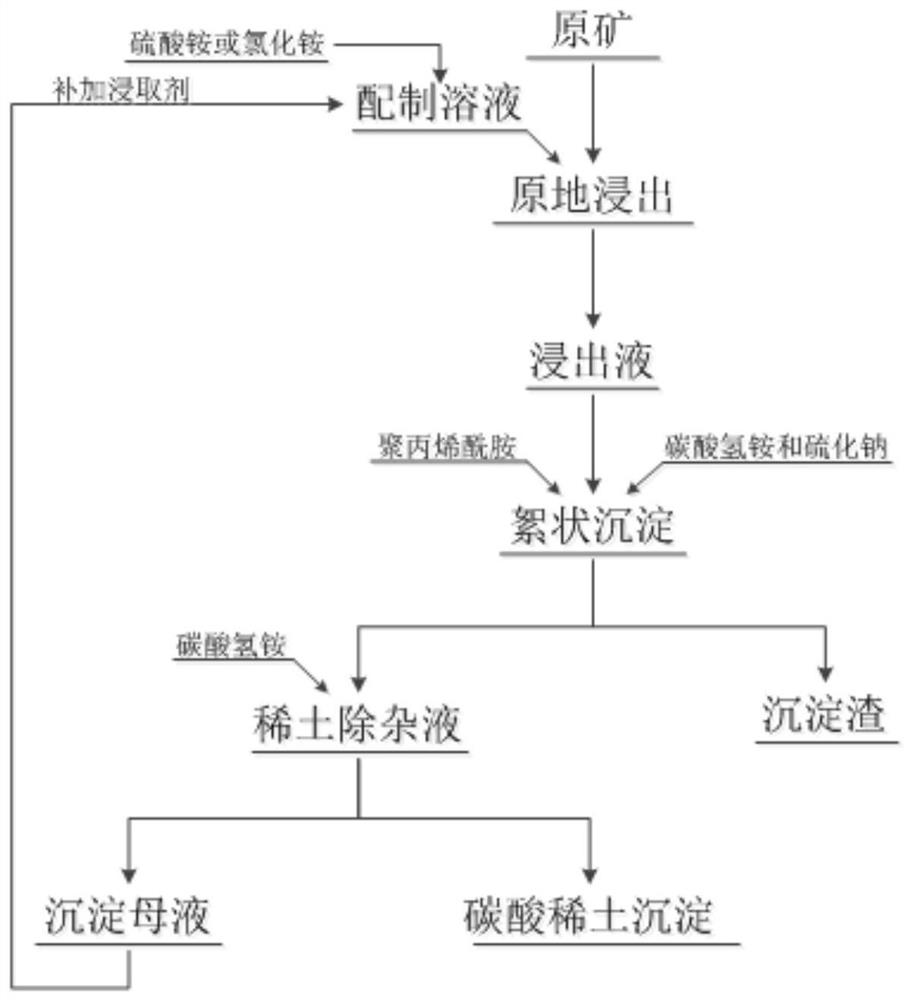

[0028] A method for reusing the mother liquor to recover rare earths after ammonium bicarbonate precipitation in the leaching solution of weathering crust elution type rare earth ore, the process flow chart is shown in figure 1 , including the following steps:

[0029] 1) Use column leaching to simulate in-situ leaching; take 5kg of a weathering crust leaching type rare earth ore in Jiangxi, the rare earth grade (REO%) is 0.09%, put the ore into a leaching column with a diameter of ф0.120m, and use a flow metering pump to gradually Add 10L of leaching solution of 2wt% ammonium sulfate, carry out column leaching, collect the leaching solution until the leaching solution stops dripping, and obtain 7.7L of leaching solution, wherein the rare earth concentration (REO) is 0.53g / L, and the rare earth leaching rate is 90.6%;

[0030] 2) Under constant stirring, use a saturated solution of ammonium bicarbonate with a sodium sulfide content of 4wt% as a mixed precipitant to adjust the ...

Embodiment 2

[0035] A method for reusing the mother liquor to recover the rare earth after the ammonium bicarbonate leaching solution of the weathering crust elution type rare earth ore precipitates the rare earth, comprising the following steps:

[0036]1) Use column leaching to simulate in-situ leaching; take 5kg of a weathering crust leaching type rare earth ore in Guangdong, the rare earth grade (REO%) is 0.08%, put the ore into a leaching column with a diameter of ф0.120m, and use a flow metering pump to gradually Add 10L of leaching solution of 2wt% ammonium sulfate, carry out column leaching, collect the leaching solution until the leaching solution stops dripping, and obtain 7.6L of leaching solution, wherein the rare earth concentration (REO) is 0.47g / L, and the rare earth leaching rate is 89%;

[0037] 2) Under stirring conditions, use a saturated solution of ammonium bicarbonate with a sodium sulfide content of 4wt% as a mixed precipitant to adjust the pH value of the leaching so...

Embodiment 3

[0041] A method for reusing the mother liquor to recover the rare earth after the ammonium bicarbonate leaching solution of the weathering crust elution type rare earth ore precipitates the rare earth, comprising the following steps:

[0042] 1) Take 5kg of a weathered crust elution-type rare earth ore from the China-Myanmar border plate tile, the rare earth grade (REO%) is 0.08%, put the ore into a leaching column with a diameter of ф0.120m, and gradually add 2wt% of the liquid with a flow metering pump Ammonium sulfate leaching agent solution 10L, carry out column leaching, collect leachate, until dripping leachate, obtain leachate 7.8L, wherein rare earth concentration (REO) is 0.64g / L, rare earth leaching rate 91%;

[0043] 2) Under stirring conditions, use sodium sulfide containing 4wt% ammonium bicarbonate as a mixed precipitant, adjust the pH value of the leaching solution to 4.8, and make aluminum ions and heavy metal ions form aluminum hydroxide and sulfides respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com