Resistive layer self-gating resistive random access memory as well as building method and application thereof

A technology of resistive memory and construction method, applied in the direction of electrical components, etc., to achieve the effect of perfect compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

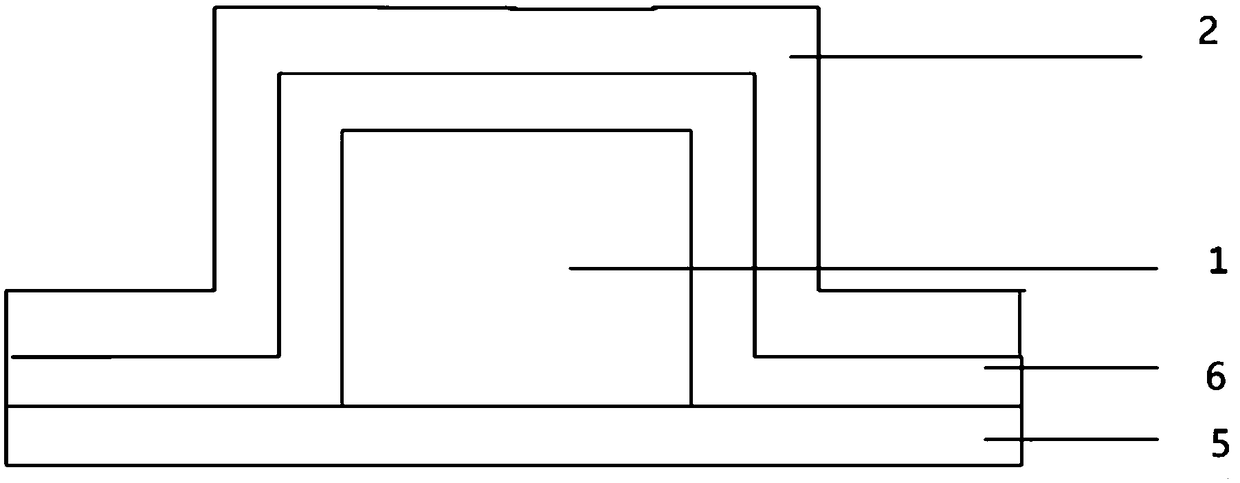

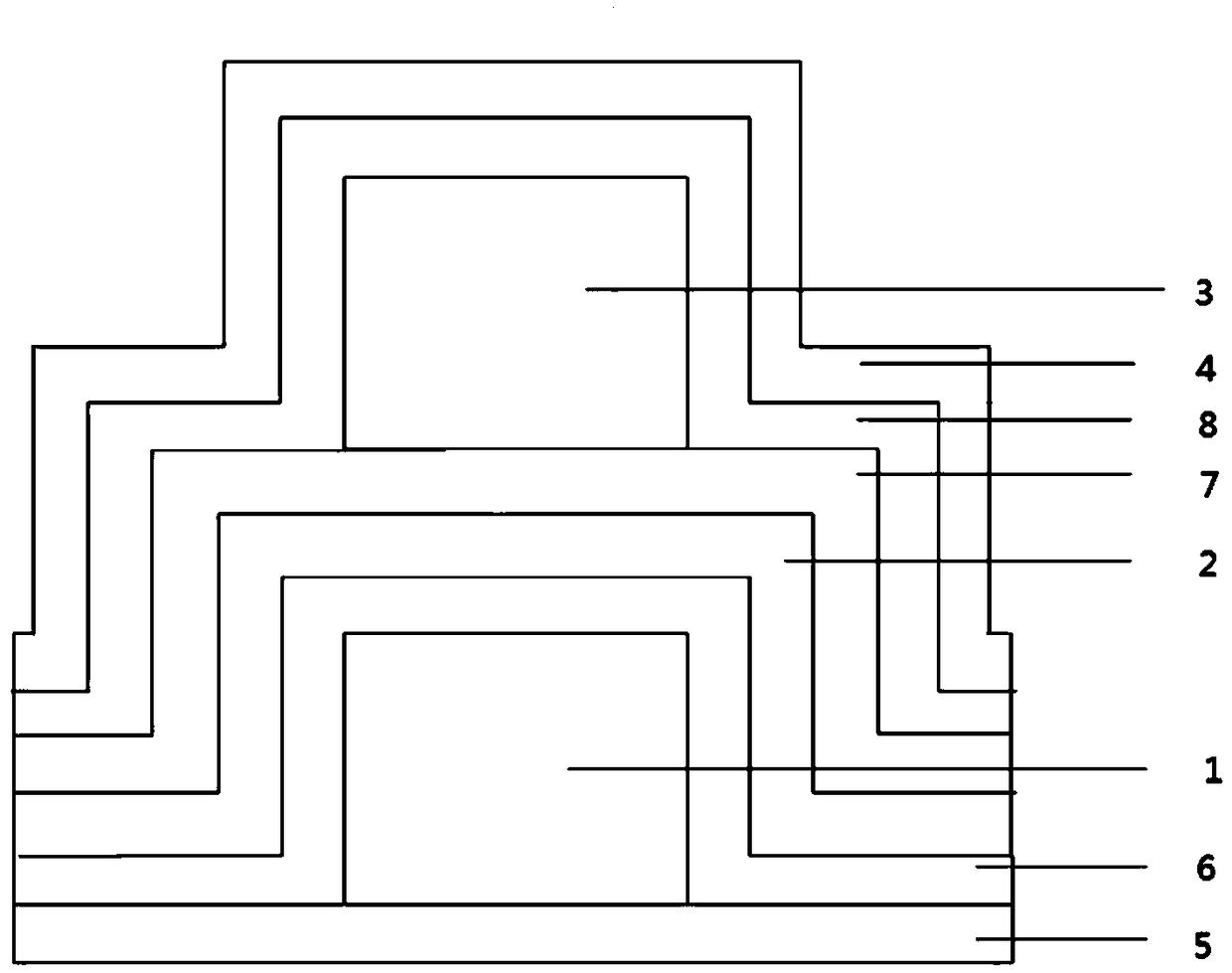

[0063] A resistive variable layer self-selection resistive variable memory, comprising a stacked layer; the stacked layer includes a fourth Hf layer 4, a fourth Si 3 N 4 Layer 8, third Hf layer 3, third Si 3 N 4 Layer 7, second Hf layer 2, second Si 3 N 4 Layer 6, first Hf layer 1 and first Si 3 N 4 Layer 5; the left and right sides of the stacked layer are respectively provided with a bottom electrode and a top electrode; the bottom electrode and the fourth Si 3 N 4 Layer 8, the third Si 3 N 4 Layer 7 communicates with the second Hf layer 2 and is arranged on the upper surface of the second Hf layer 2; the top electrode communicates with the entire stack layer and is arranged on the first Si 3 N 4 top surface of layer 5.

[0064] First Si 3 N 4 The thickness of layer 5 is 25nm; the thickness of the first Hf layer 1 is 110nm; the second Si 3 N 4 The thickness of layer 6 and the second Hf layer 2 is 25nm; the third Si 3 N 4 The thickness of layer 7 is 25nm; the...

Embodiment 2

[0067] The resistive variable layer self-selectable resistive variable memory as described in Embodiment 1, the difference is that the resistive variable layer self-selectable resistive variable memory comprises two stacked layers arranged side by side; the top electrode is a bit line; the for the word line.

Embodiment 3

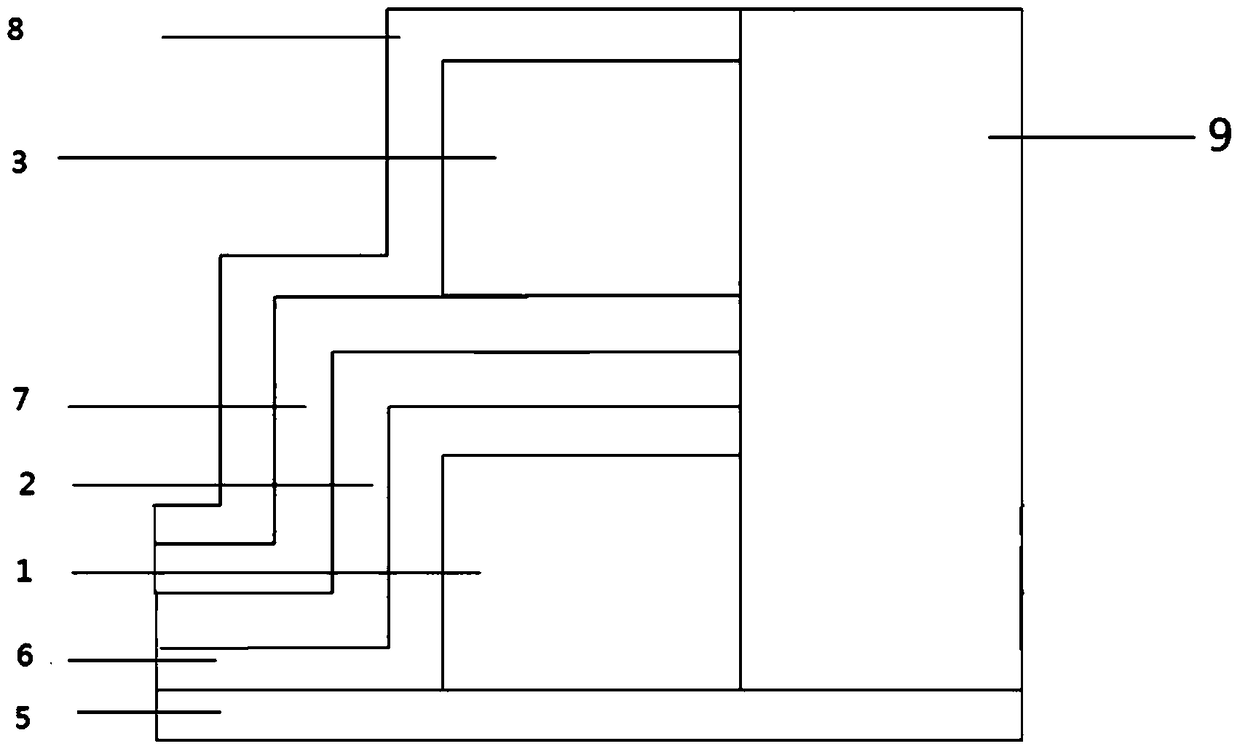

[0069] A method for constructing a resistive variable layer self-selecting resistive variable memory as described in Embodiment 1, comprising the following steps:

[0070] 1) Deposit the first Si on the substrate 3 N 4 Layer 5; depositing the first Si on the substrate 3 N 4 Layer 5 is realized by CVD method; the substrate is a Si substrate;

[0071] 2) In the first Si 3 N 4 Deposit the first Hf layer 1 on the layer 5, then perform photolithography and lift-off treatment; 3 N 4 The deposition of the first Hf layer 1 on the layer 5 is achieved by a DC sputtering method.

[0072] 3) Deposit the second Si sequentially on the first Hf layer 1 3 N 4 Layer 6, the second Hf layer 2; as figure 1 shown. Second Si 3 N 4 Layer 6 is deposited by CVD method and the second Hf layer 2 is deposited by sputtering.

[0073] 4) Deposit the third Si on the second Hf layer 2 3 N4 Layer 7, according to the method of step 2), 3) in the third Si 3 N 4 Deposit the third Hf layer 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com