Preparation method of nitrogen-doped hollow carbon sphere

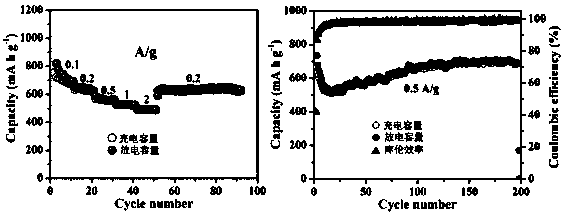

A hollow carbon sphere, nitrogen doping technology, applied in nanotechnology for materials and surface science, electrical components, electrochemical generators, etc., can solve the problem that the capacity of graphite is difficult to meet the actual needs of use, and achieve a good cycle. Stability and rate capability, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

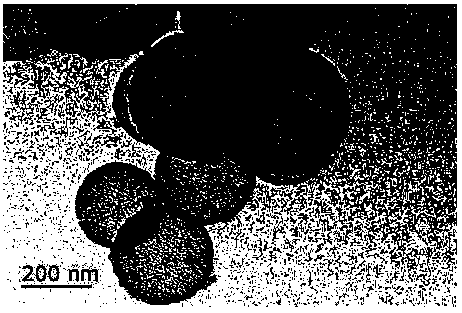

[0013] A method for preparing nitrogen-doped hollow carbon spheres, wherein 0.1-2 grams of titanium sulfate are respectively dispersed in a sulfuric acid solution of 1-10 mol / liter, and then dropwise added containing 1-10 milliliters of butyl oleate and 1-10 grams of titanium sulfate. In the reaction kettle of milliliter oleylamine, after stirring for 30 minutes, in an oven at 100-200 ° C, react for 5-20 hours, after natural cooling, the obtained white precipitate is washed with deionized water for several times, and then centrifuged. After drying at 70 °C for 12 hours, and further calcining at 400-800 °C for 2-10 hours in an argon atmosphere, carbon-coated anatase-phase titanium dioxide mesogens (TiO2) can be obtained. 2 @C) Composite nanomaterials. Further with TiO 2 @C is the precursor, dissolved in HF acid solution to remove TiO 2 template. After centrifugation and washing, N-GC hollow carbon spheres were obtained by drying in air at 70°C for 12 hours.

[0014] The nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com