A kind of preparation method of high-pressure billet strength tungsten powder

A high-strength, tungsten powder technology, applied in the field of tungsten industry, can solve problems such as cracks or edge drop, insufficient compacts, etc., and achieve the effects of simple process, improved compact strength, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

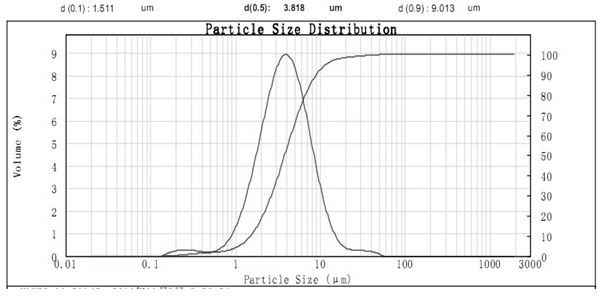

[0026] Conventional powder preparation method: use YTO as a raw material for reduction in a reduction furnace, in which the thickness of the material layer is controlled between 8 and 14mm, the heating rate is 50°C / h, and the hydrogen dew point is -65°C to -70°C; five-zone reduction The temperature distribution is within the range of 750-900°C, and the residence time in the high-temperature zone is 150-160 minutes; the reduced powder is sieved twice with 80 / 160 mesh, and finally the conventional powder is obtained, which is sealed and stored.

Embodiment 2

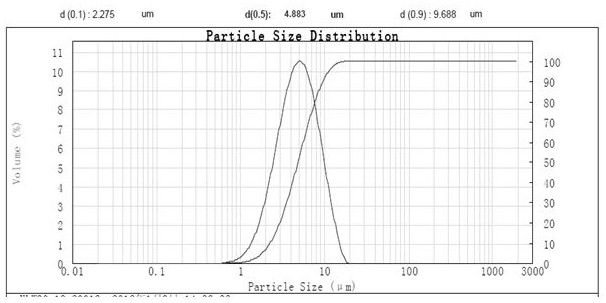

[0028] Preparation method of high slab strength powder: After mixing BTO\PTO\YTO in the ratio of 2:5:10 in the double cone mixer for 2.0 hours, the mixture of these three tungsten oxides is used as the raw material, and the raw materials are laid flat Reduction is carried out in a reduction furnace in a boat. The material layer thickness is controlled between 10-12mm, the heating rate is 50°C / h, the hydrogen dew point is -70°C--75°C; the five-zone reduction temperature is 720°C for the first zone and 770°C for the second zone , The temperature of the third zone is 820°C, the temperature of the fourth zone is 860°C, and the temperature of the fifth zone is 920°C; the time of staying in each high temperature zone is 35min; the reduced powder is sieved twice with 80 / 200 mesh , and finally obtain a high green strength powder, which is sealed and stored.

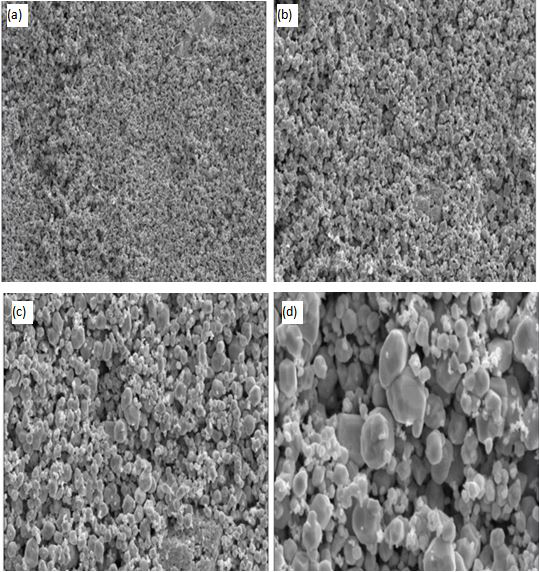

[0029] Through the comparison of the above two processes, it is not difficult to find that the high pressure blank strength po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com