Device for preparing high-quality high-depth-diameter-ratio micro hole by using light ray obtained through femtosecond laser time domain/space shaping

A femtosecond laser, high aspect ratio technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficulty in adjusting the diameter of micropores, limiting the practical application of micropores, and limited depth-diameter ratio of micropores. The effect of wide adjustment range of hole diameter, large aspect ratio and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

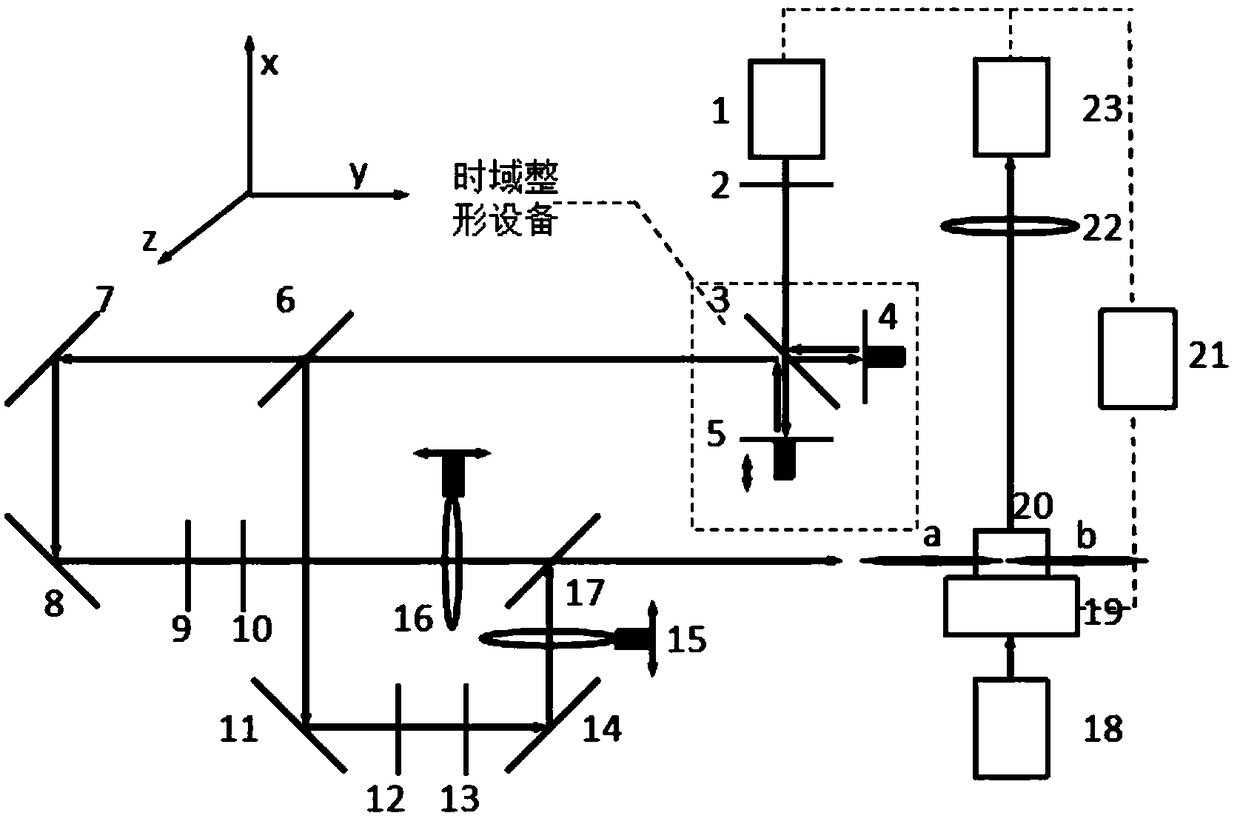

[0017] The pulse time domain shaping device used is a double pulse generator similar to Michelson interferometer;

[0018] Turn on the mechanical switch 2, the laser emitted from the femtosecond laser 1 reaches the first beam splitter 3 placed at an angle of 45° to the light propagation direction, the reflected light reaches the first beam splitter 3 after being reflected by the first mirror 4, and the transmitted light is After being reflected by the second reflecting mirror 5, it also reaches the first beam splitter 3. The first reflector 4 and the second reflector 5 are adjusted so that the two beams of light reflected by them pass through the first beam splitter 3 to form a spatially coincident pulse sequence.

[0019] The second reflection mirror 5 is adjusted by using the translation stage, so that the two beams of light reflected by the first reflection mirror 4 and the second reflection mirror 5 also coincide in the time domain.

[0020] After the femtosecond laser pu...

Embodiment 2

[0029] The pulse time-domain shaping device used is a commercial pulse shaper, which is used to replace the first beam splitter 3, the first mirror 4, and the second mirror 5 in the above example.

[0030] Turn on the mechanical switch 2, the laser light emitted from the femtosecond laser 1 enters the pulse shaper, and the time-domain pulse sequence emitted from the pulse shaper reaches the second beam splitter 6, and is divided into reflected light and transmitted light with equal energy. The reflected light is focused by the first focusing lens 15 after passing through the fifth reflector 11, the second half-wave plate 12, the second polarizer 13, and the sixth reflector 14 in sequence; the transmitted light passes through the third reflector 7 and the fourth reflector in sequence. The mirror 8, the first half-wave plate 9, and the first polarizer 10 are then focused by the second focusing lens 16.

[0031] Block one of the focusing lenses so that the femtosecond laser pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com