Graphite purifying method

A graphite purification and graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve environmental hazards, environmental pollution and other problems, and achieve the effects of small environmental pollution, shortened time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

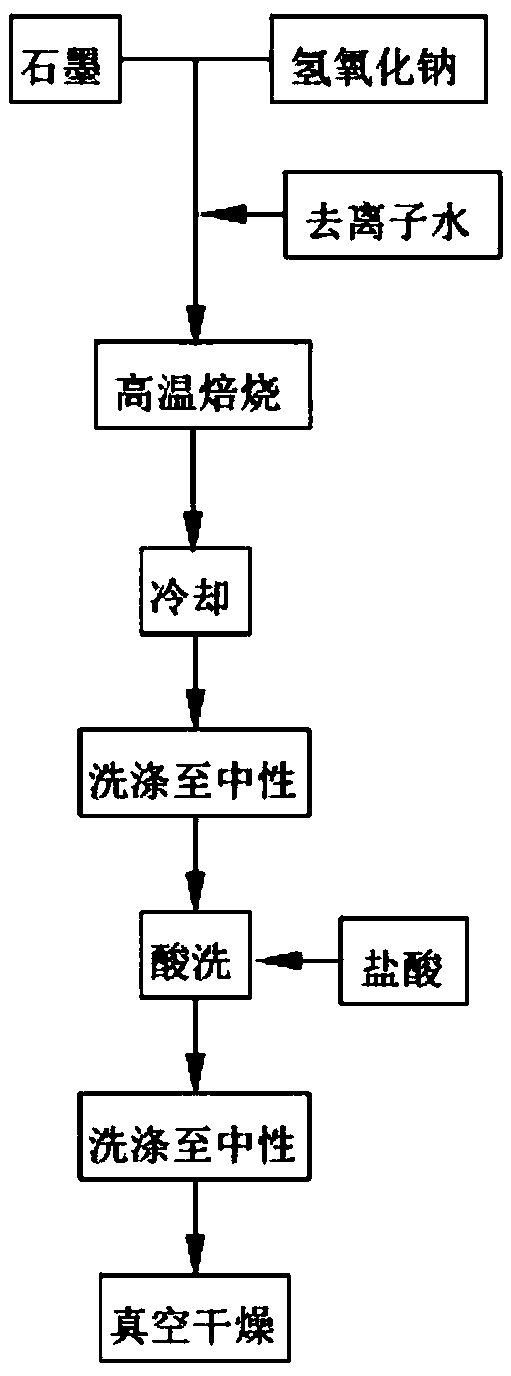

Image

Examples

Embodiment 1

[0019] A kind of graphite purification method comprises the following steps:

[0020] 1) Preparation of raw materials:

[0021] 1. raw material preparation: prepare 100 parts of graphite, 40 parts of sodium hydroxide, a sufficient amount of deionized water, and 40 parts of hydrochloric acid with a concentration of 1mol / L by weight;

[0022] ②Equipment and tooling preparation: crucible, box-type resistance furnace, magnetic stirrer, vacuum drying oven;

[0023] 2) The purification process is as follows:

[0024] ①Put the graphite and sodium hydroxide prepared in stage 1) step ① into the crucible together, and add 100 parts of deionized water into the crucible, and stir evenly with a glass rod;

[0025] ②Put the crucible prepared in stage 1) step ① into the box-type resistance furnace, keep the heating rate at 10°C / min, until the temperature in the box-type resistance furnace reaches 600°C, keep it warm for 2 hours, and then let the box-type resistance furnace naturally Cooli...

Embodiment 2

[0028] A graphite purification method, comprising the following steps:

[0029] 1) Preparation of raw materials:

[0030] 1. raw material preparation: prepare 200 parts of graphite, 80 parts of sodium hydroxide, sufficient amount of deionized water, and 80 parts of hydrochloric acid with a concentration of 1mol / L by weight;

[0031] ②Equipment and tooling preparation: crucible, box-type resistance furnace, magnetic stirrer, vacuum drying oven;

[0032] 2) The purification process is as follows:

[0033] ①Put the graphite and sodium hydroxide prepared in stage 1) step ① into the crucible together, and add 150 parts of deionized water into the crucible, and stir evenly with a glass rod;

[0034] ②Put the crucible prepared in stage 1) step ① into the box-type resistance furnace, keep the heating rate at 10°C / min, until the temperature in the box-type resistance furnace reaches 800°C, keep it for 4 hours, and then let the box-type resistance furnace naturally Cooling, take out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com