Method for preparing egg albumen ACE (angiotensin converting enzyme) inhibiting peptide by utilizing ultrahigh pressure synergetic enzymolysis

An ultra-high pressure, inhibitory peptide technology, applied in the biological field, to achieve the effect of increasing contact sites, improving ACE inhibitory activity, and sufficient enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

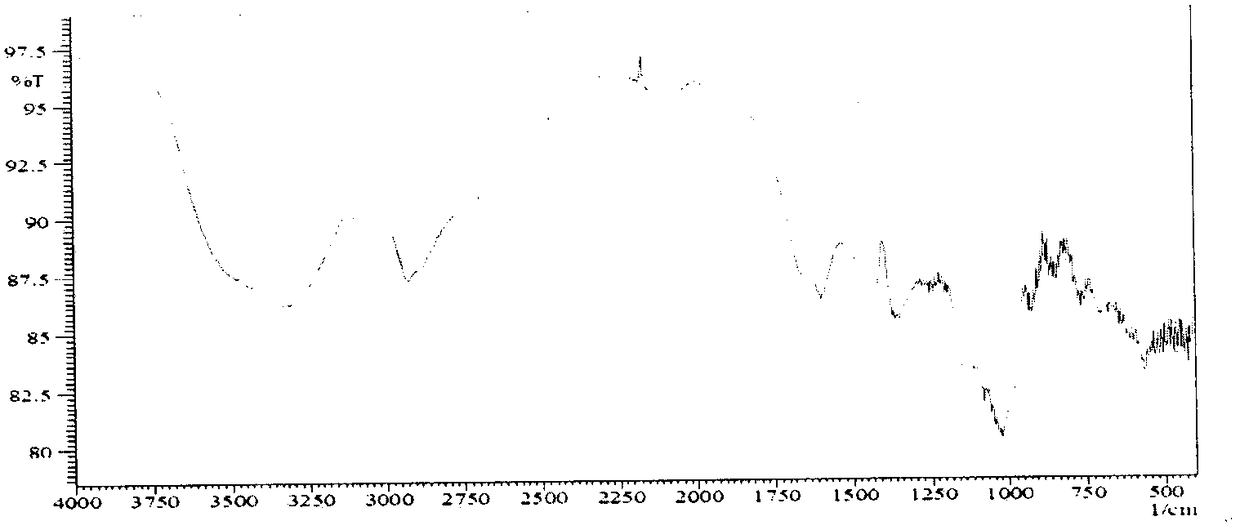

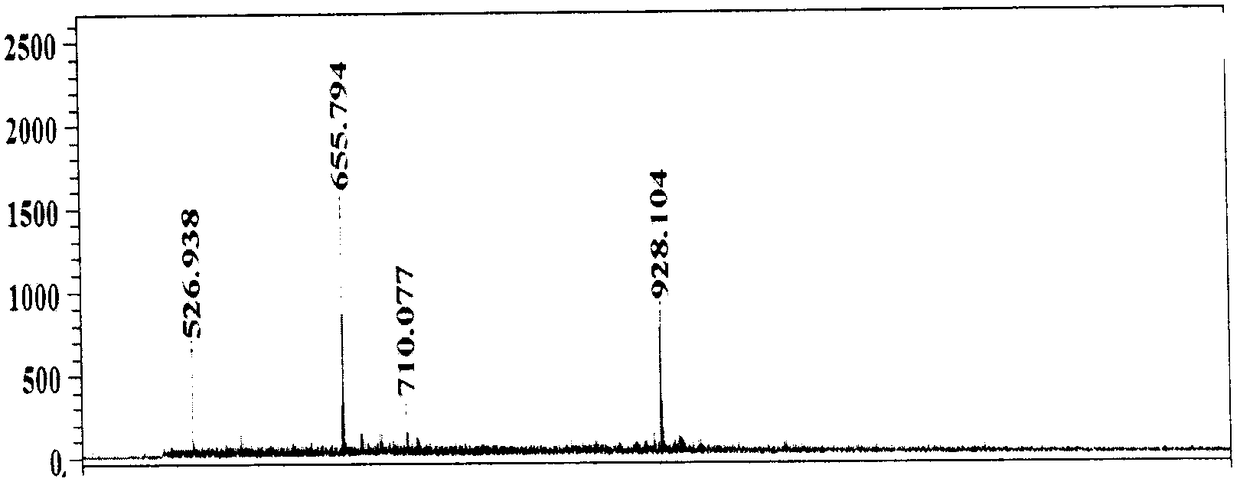

Image

Examples

Embodiment 1

[0022] (1) The egg white powder is formulated into an aqueous solution with a mass fraction of 8%, and then the egg white powder solution is placed in a vacuum bag for sealing. Put the packaged egg white powder solution under a pressure of 400Mpa, keep the temperature at 30°C, reach the set pressure after 1 to 2 minutes, hold the pressure for 20 minutes, and take it out after 1 to 2 minutes after the treatment time is over.

[0023] (2) Enzymolyze the sample after ultra-high pressure treatment: adjust the pH value to 9 with 0.2mol / L sodium hydroxide solution, place it in a constant temperature water bath at 56°C, add 5% Alcalase protease for enzymolysis, and enzymolysis 3 Hour. During the enzymatic hydrolysis process, a stirrer should be used to continuously stir, and 0.2 mol / L sodium hydroxide solution should be added every half hour to maintain the pH value at 9±0.05. Record the amount of alkali added each time, and calculate the total amount, and use the pH-stat method to ...

Embodiment 2

[0026] (1) The egg white powder is formulated into an aqueous solution with a mass fraction of 8%, and then the egg white powder solution is placed in a vacuum bag for sealing. Put the packaged egg white powder solution under a pressure of 400Mpa, keep the temperature at 30°C, reach the set pressure after 1 to 2 minutes, hold the pressure for 20 minutes, and take it out after 1 to 2 minutes after the treatment time is over.

[0027] (2) Enzymolyze the sample after ultra-high pressure treatment: adjust the pH value to 9 with 0.2mol / L sodium hydroxide solution, place it in a constant temperature water bath at 56°C, add 5% Alcalase protease for enzymolysis, and enzymolysis 3 Hour. During the enzymatic hydrolysis process, a stirrer should be used to continuously stir, and 0.2 mol / L sodium hydroxide solution should be added every half hour to maintain the pH value at 9±0.05. Record the amount of alkali added each time, and calculate the total amount, and use the pH-stat method to ...

Embodiment 3

[0030] (1) The egg white powder is formulated into an aqueous solution with a mass fraction of 8%, and then the egg white powder solution is placed in a vacuum bag for sealing. Put the packaged egg white powder solution under the pressure of 400Mpa, keep the temperature at 30°C, reach the set pressure after 1-2 minutes, keep the pressure for 20 minutes, and release the pressure for 1-2 minutes after the treatment time is over.

[0031] (2) Enzymolyze the sample after ultra-high pressure treatment: adjust the pH value to 9 with 0.2mol / L sodium hydroxide solution, place it in a constant temperature water bath at 56°C, add 5% Alcalase protease for enzymolysis, and enzymolysis 3 Hour. During the enzymatic hydrolysis process, a stirrer should be used to continuously stir, and 0.2 mol / L sodium hydroxide solution should be added every half hour to maintain the pH value at 9±0.05. Record the amount of alkali added each time, and calculate the total amount, and use the pH-stat method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com