Heat treatment process method for duplex stainless steel

A technology of duplex stainless steel and process method, applied in the field of material heat treatment, can solve the problems of poor mechanical properties and easy precipitation of σ equal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of heat treatment process method of duplex stainless steel, it comprises the following steps:

[0025] Step 1: Place the duplex stainless steel casting 1.4469 in a high-pressure gas-quenching vacuum furnace, raise the temperature to 1100°C within 3 hours under the protection of nitrogen, and keep it warm for 3 hours;

[0026] Step 2: In a nitrogen environment with a purity of 99.99% and a pressure of 800Kpa, use nitrogen as a cooling medium to air-cool and quench the heated workpiece, drop it to 960°C after 2s, and then drop it to 460°C after 48s. Then continue cooling to room temperature.

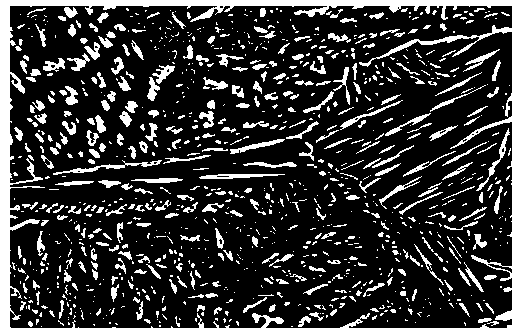

[0027] The metallographic diagram of the treated duplex stainless steel casting 1.4469 is as follows image 3 , Figure 4 As shown, there is no σ phase precipitation, and the metallographic structure is uniform.

[0028] Carry out mechanical property test to two samples processed by the above steps:

[0029] Sample 1: ultimate tensile strength 718Mpa, yield ...

Embodiment 2

[0032] Embodiment 2: a kind of heat treatment process method of duplex stainless steel, it comprises the following steps:

[0033] Step 1: Place the duplex stainless steel casting 1.4469 in a high-pressure gas quenching vacuum furnace, raise the temperature to 1140°C within 3 hours under the protection of nitrogen, and keep it warm for 4 hours;

[0034] Step 2: In a nitrogen environment with a purity of 99.999% and a pressure of 1000Kpa, use nitrogen as a cooling medium to air-cool and quench the heated workpiece, and drop it to 920°C after 1.5s, and then drop it to 300°C after 28.5s °C, and then continued to cool to room temperature.

[0035] The metallographic diagram of the treated duplex stainless steel casting 1.4469 is as follows Figure 5 , Figure 6 As shown, there is no σ phase precipitation, and the metallographic structure is uniform.

[0036] Carry out mechanical property test to two samples processed by the above steps:

[0037] Sample 1: ultimate tensile stre...

Embodiment 3

[0040] Embodiment 3: a kind of heat treatment process method of duplex stainless steel, it comprises the following steps:

[0041] Step 1: Place the duplex stainless steel casting 1.4469 in a high-pressure gas quenching vacuum furnace, raise the temperature to 1120°C within 3 hours under the protection of nitrogen, and keep it warm for 3.5 hours;

[0042] Step 2: In a nitrogen environment with a purity of 99.995% and a pressure of 900Kpa, use nitrogen as a cooling medium to air-cool and quench the heated workpiece, and drop it to 920°C after 2s, and then drop it to 350°C after 38s. Then continue cooling to room temperature.

[0043] The metallographic diagram of the treated duplex stainless steel casting 1.4469 is as follows Figure 7 , Figure 8 As shown, there is no σ phase precipitation, and the metallographic structure is uniform.

[0044] Carry out mechanical property test to two samples processed by the above steps:

[0045] Sample 1: ultimate tensile strength 735Mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com