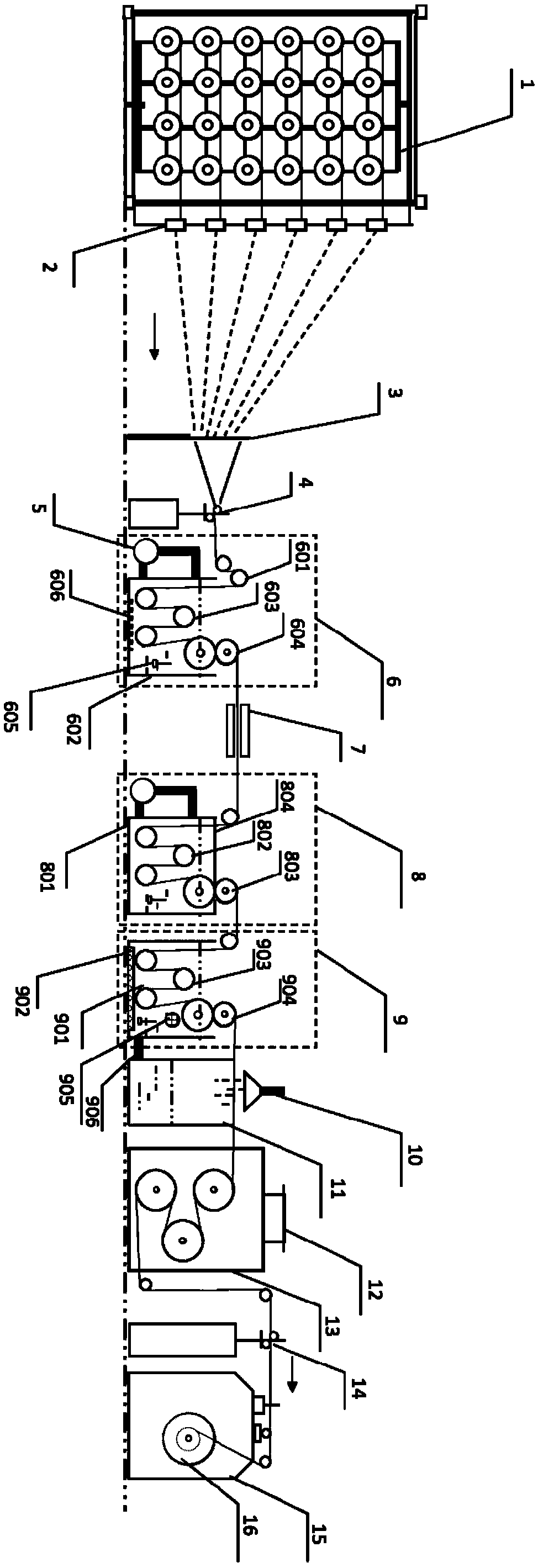

Surface polymerization and continuous treatment warping machine for composite conductive yarns

A composite conductive and warping machine technology, applied in warping machine, textile material processing, liquid/gas/vapor yarn/filament processing and other directions, can solve the problem of low utilization rate of raw materials, low yield, and limited application of conductive yarns and other problems, to achieve the effect of improving conductivity and stability, improving conductivity and stability, and efficient and practical processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

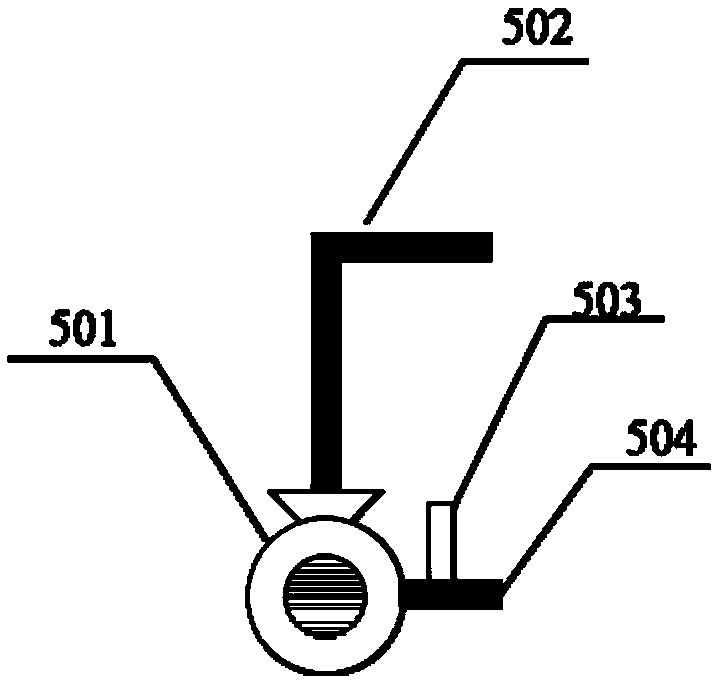

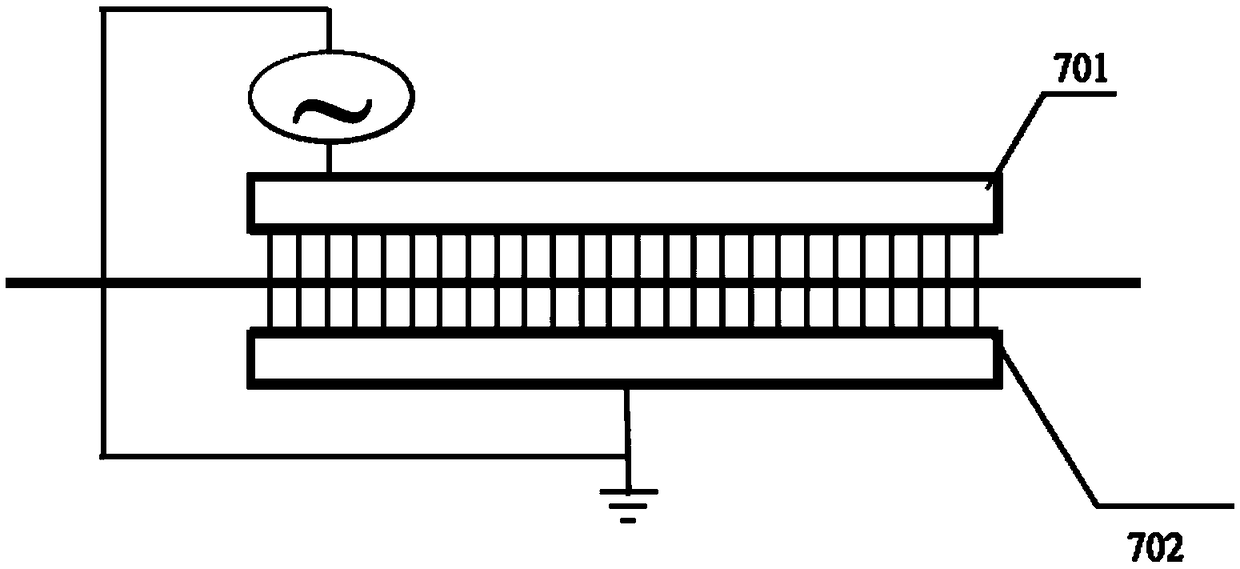

Method used

Image

Examples

Embodiment 1

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the description of the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0027] Conventional conductive material polymerization process: cotton yarn specification is 32 S , yarn running speed 2m / min, cotton yarn rinsing time 40min, Na 2 CO 3 3g / L, detergent 5g / L, bath ratio 1:50, temperature 80°C; cotton yarn impregnation treatment time 1h; conductive material monomer 0.4mol / L, bath ratio 1:50-100, normal temperature; in-situ polymerization tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com