A two-stroke hybrid-drive micro-nano indentation/scratch testing device

A technology of hybrid drive and scratch testing, which is applied in the direction of measuring devices, testing material hardness, instruments, etc., can solve the problems that the two loading modes of high precision and large stroke cannot be realized at the same time, so as to achieve improvement, optimization, maintenance, Compact layout for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

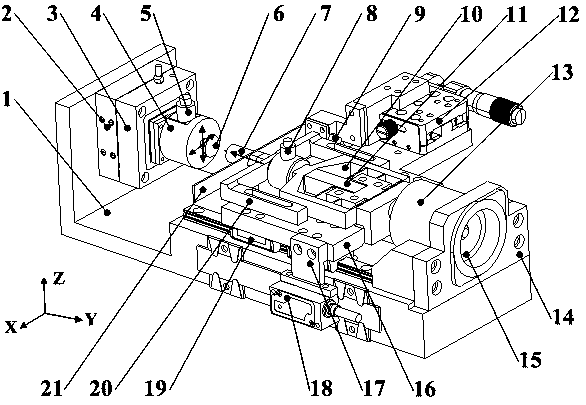

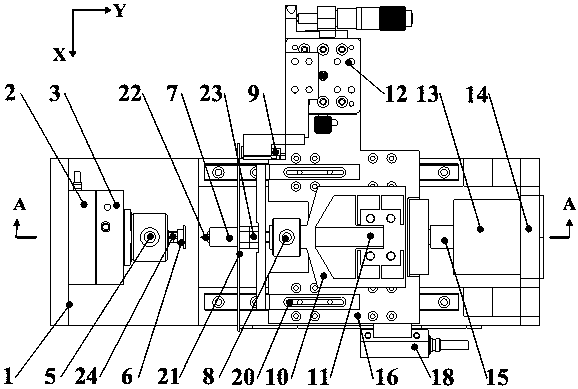

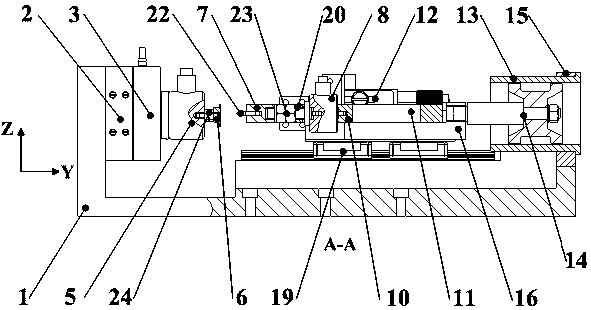

[0023] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1 to Figure 5 As shown, the dual-stroke hybrid drive micro-nano indentation / scratch test device of the present invention can not only realize conventional nano-indentation / scratch tests on bulk metal materials, thin film materials, and composite materials, but also on biological tissues, etc. Soft materials are subjected to a large-stroke loading test, which is more practical. The invention utilizes the voice coil motor, piezoelectric stack-flexible hinge to realize hybrid drive, adjusts the assembly relationship between the shield (frame) and the force sensor, adopts the segmented load detection and range switching mode, and combines the displacement detection unit to realize different loading strokes And the accurate measurement of the indentation load, and the integrated sample moving unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com