Quantitative analysis method of metal phase volume fraction gradient distribution of cutting surface layer of duplex titanium alloy

A cutting and volume fraction technology, applied in material analysis using measurement of secondary emissions, material analysis, material analysis using wave/particle radiation, etc. resolution and other issues, to achieve the effect of high-precision identification, significant progress, and highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

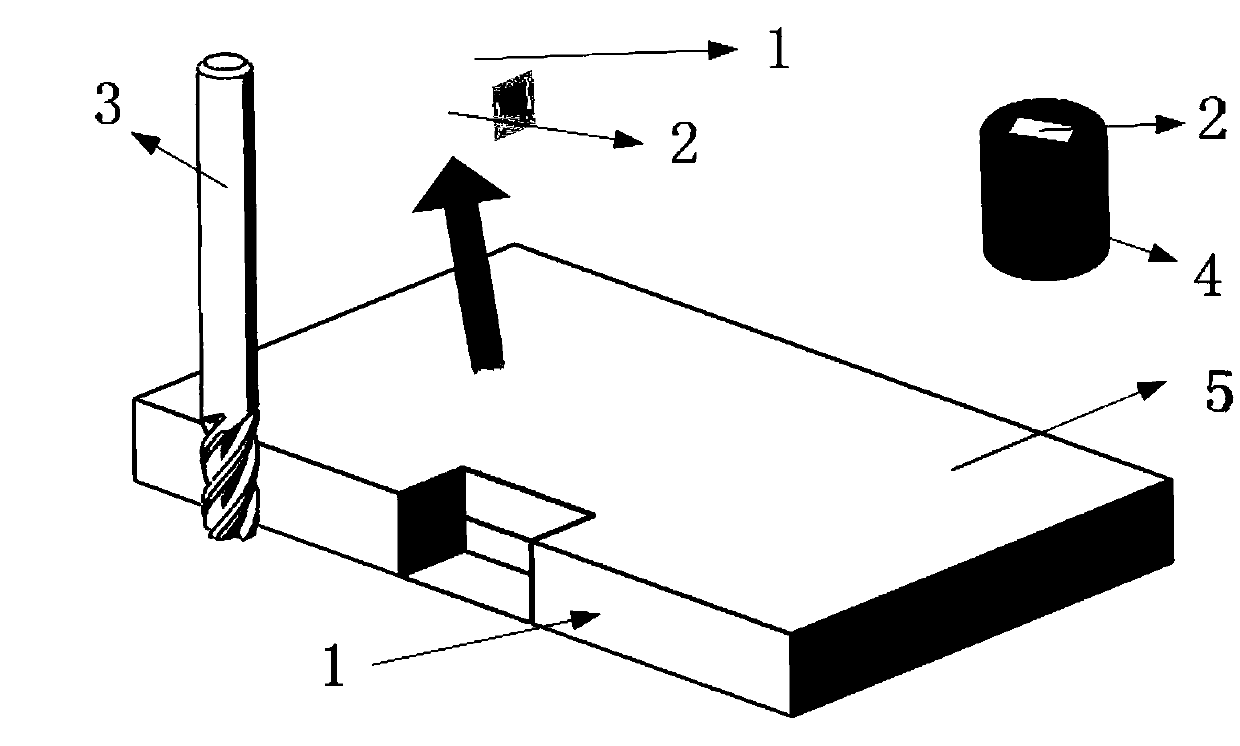

[0043] The middle area of the processed surface of the workpiece is selected to make a rectangular sample by wire cutting, and the side sections are respectively used as the detection surface to inlay the test block. The schematic diagram of the test block sampling process is as follows: figure 1 shown. figure 1 The middle arrow 1 points to the cutting surface, the arrow 2 points to the side profile, the arrow 3 points to the cutting tool, the arrow 4 points to the mosaic test block, and the arrow 5 points to the processed titanium alloy material.

[0044] After grinding (2000 mesh sandpaper) and polishing, the test piece test surface was put into the corrosive solution at room temperature for 10 seconds. The formula and performance parameters of the corrosive solution are listed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com