Solid-state light source lighting system integrated packaging structure and manufacturing method

A light-emitting system, solid-state light source technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as unfavorable lighting effects, large circuit board area, etc., to reduce the area, improve product consistency and stability, reduce high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

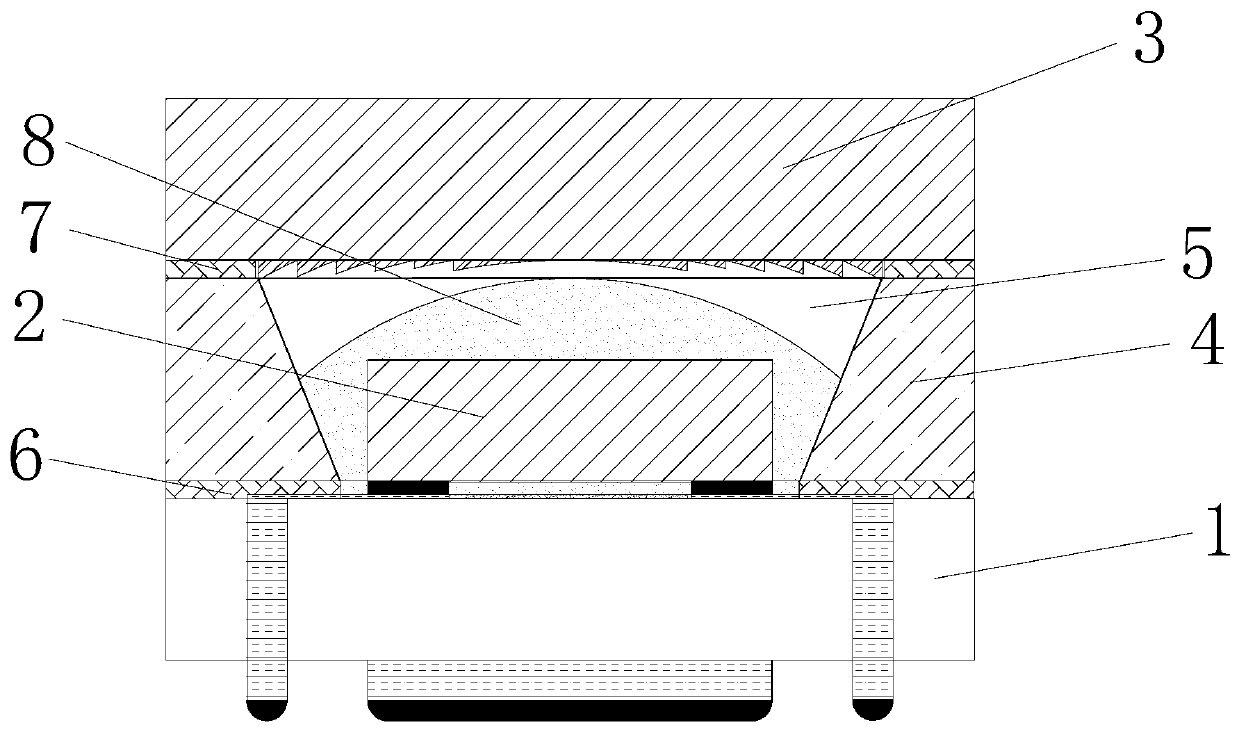

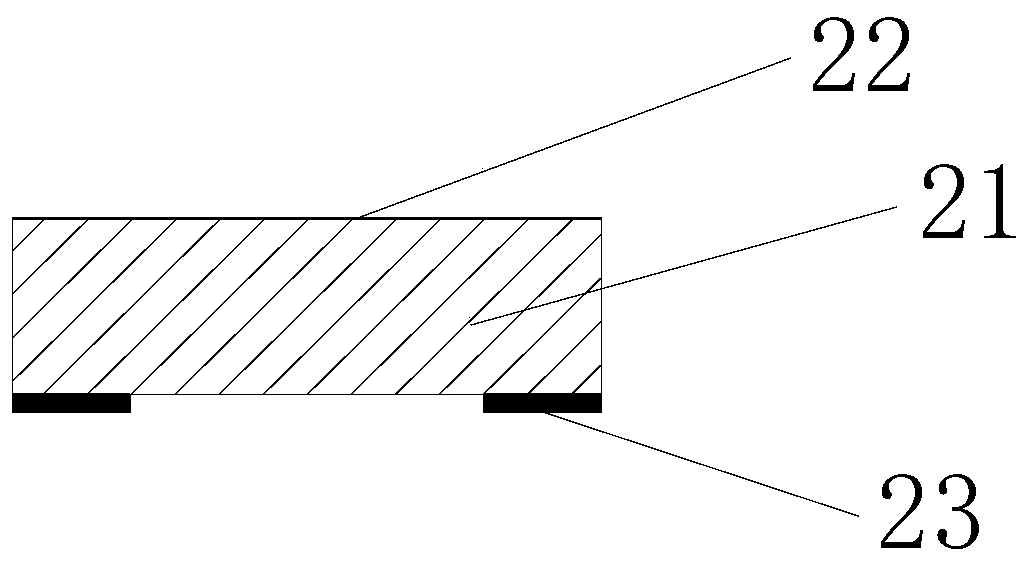

[0065] Such as Figure 1 to Figure 5 As shown, this embodiment provides an integrated packaging structure for a solid-state light source lighting system, the packaging structure includes a light source driver chip 1, a solid-state light-emitting light source chip 2 and a lens 3, and the light source driver chip 1 and the lens 3 are connected through a filler 4 The filler 4 forms a cavity 5 between the light source driving chip 1 and the lens 3 , the solid state light emitting source chip 2 is mounted on the back of the light source driving chip 1 , and the solid state light emitting light source chip 2 is located in the cavity 5 .

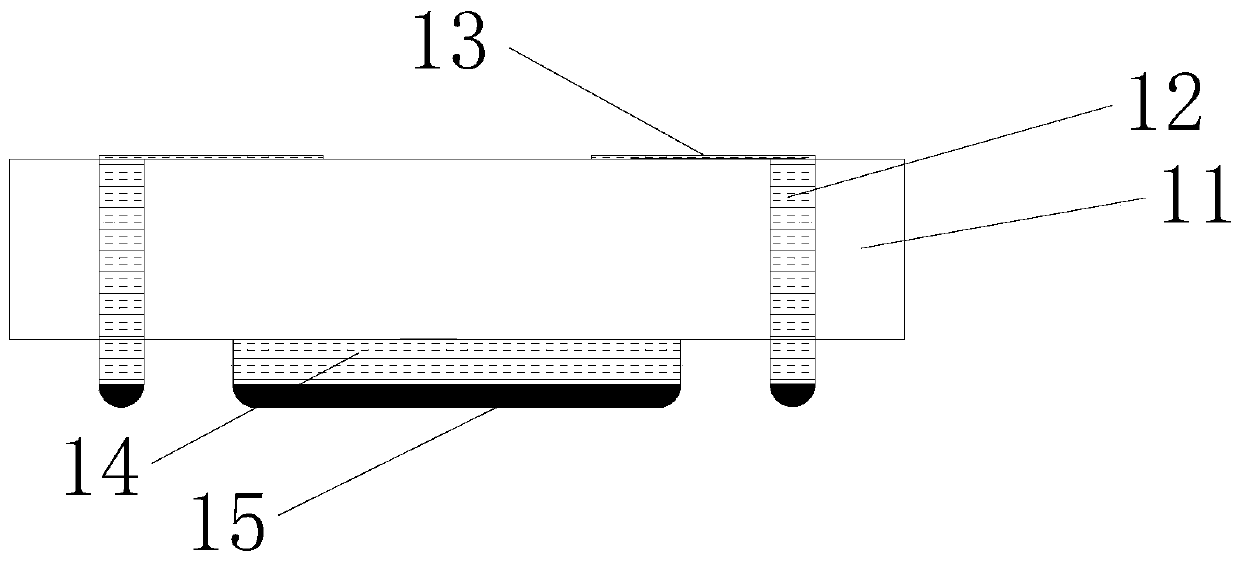

[0066] The light source driving chip 1 is used to control the current and voltage of the solid-state light-emitting light source chip 2, and adjust the luminous intensity of the solid-state light-emitting light source chip 2. It includes a driving chip body 11, and a through hole 12 is provided on the driving chip body 11. Specifically, The through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com