A kind of anti-fouling and hydrophobic ceramic utensil and its manufacturing method

A technology for ceramics and utensils, which is applied in the field of anti-fouling and hydrophobic ceramic utensils and its production. It can solve the problems that water stains are easy to stay on the surface of utensils, water stains penetrate into the interior of ceramic utensils, and stain repellency is not strong, etc., to achieve significant anti-fouling and hydrophobicity. Ability, strong anti-fouling and hydrophobic ability, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

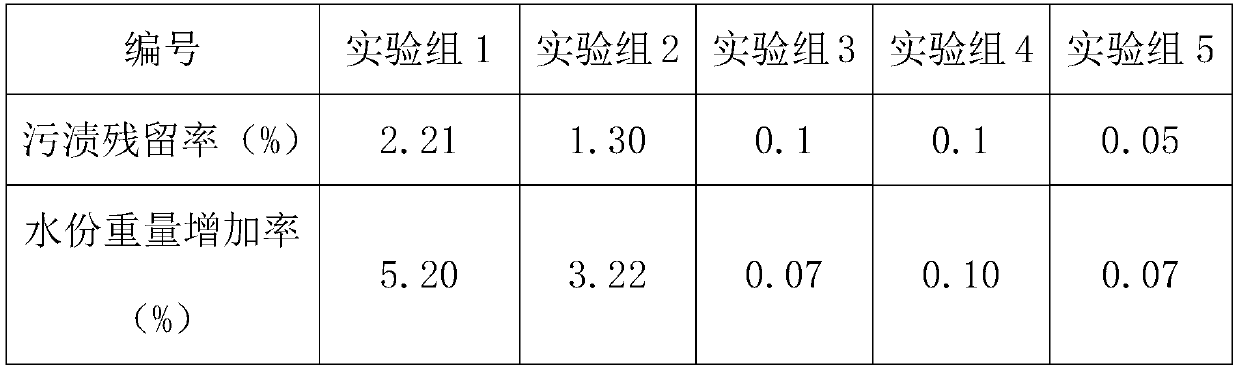

Examples

Embodiment 1

[0037] This embodiment provides a kind of anti-fouling and hydrophobic ceramic utensil and its manufacturing method:

[0038] 1. The raw materials of the anti-fouling and hydrophobic ceramic utensils include: 96.00% of clay, 3.00% of silicon dioxide, 0.09% of aluminum oxide, and 0.91% of methyltrioxyethylsilane in terms of weight percentage.

[0039] 2. Production method:

[0040] S1. Forming of symmetrical ceramic utensils: Weigh the raw materials according to the proportion of the formula, add water ball mill, press filter, rough refining, stale, refining, rolling forming, and obtain the ceramic green body;

[0041] S2. Drying: microwave drying technology is used to dry the ceramic body, and the microwave frequency is 250 MHz;

[0042] S3. Blank trimming: Trimming the dried ceramic body by means of friction;

[0043] S4. Water replenishment: After soaking the trimmed ceramic body with clear water, rub the ceramic body;

Embodiment 2

[0052] This embodiment provides a kind of anti-fouling and hydrophobic ceramic utensil and its manufacturing method:

[0053] 1. The raw materials of the anti-fouling and hydrophobic ceramic utensils include, by weight percentage: 93.50% kaolin, 5.26% silicon dioxide, 0.18% aluminum oxide, and 1.06% methyltrioxyethylsilane.

[0054] 2. Production method:

[0055] S1. Irregular ceramic utensil molding: Weigh the raw materials according to the formula ratio, add water ball mill, press filter, rough refining, stale, refining, high-pressure grouting molding, and obtain the ceramic body;

[0056] S2. Drying: microwave drying technology is used to dry the ceramic body, and the microwave frequency is 295 MHz;

[0057] S3. Blank trimming: Trimming the dried ceramic body by means of friction;

[0058] S4. Water replenishment: After soaking the trimmed ceramic body with clear water, rub the ceramic body;

[0059] S5. Glazing: use a ceramic glazing machine to glaze the water-replenish...

Embodiment 3

[0067] This embodiment provides a kind of anti-fouling and hydrophobic ceramic utensil and its manufacturing method:

[0068] 1. The raw materials of the anti-fouling and hydrophobic ceramic utensils include: 94.28% of a mixture of kaolin and clay (any ratio is required), 4.75% of silicon dioxide, 0.12% of aluminum oxide, and 0.85% of methyltrioxyethylsilane .

[0069] 2. Production method:

[0070] S1. Forming of symmetrical ceramic utensils: Weigh the raw materials according to the proportion of the formula, add water ball mill, press filter, rough refining, stale, refining, rolling forming, and obtain the ceramic green body;

[0071] S2. Drying: microwave drying technology is used to dry the ceramic body, and the microwave frequency is 280 MHz;

[0072] S3. Blank trimming: Trimming the dried ceramic body by means of friction;

[0073] S4. Water replenishment: After soaking the trimmed ceramic body with clear water, rub the ceramic body;

[0074] S5. Glazing: use a ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com